WAYS AND MEANS.

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

Useful Contributions From Our Driver and Mechanic Readers.

Removing Dents.

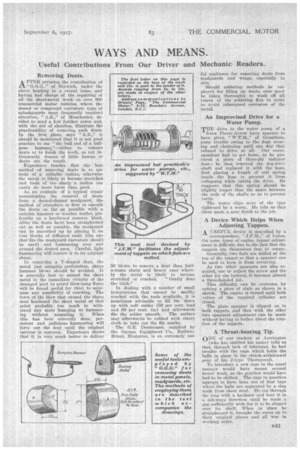

ATER perusing the eontribution of " F' G.G.Gr.," of Norwich, under the above heading in a recent issue, and having had charge of the repairing of all the sheet-metal work on over 600 commercial motor vehicles where the • domed or compound curvature type of splashguards most frequently required attention, " A.E.," of Manchester, decided to send a few further notes and, with the aid of sketches, illustrate the practicability of removing such dents. In the first place, says "A.E.," it should be mentioned that it is not good practice to use "the ball end of a ballpone hammer..."—either to remove dents or to finish the work, as not infrequently dozens of little bumps or dents are the result.

Experience teaches that the 'best method of removing dents is to use tools of a snitable radius, otherwise the metal is likely to become stretched and tools of too sharp a radius can easily do more harm than good.

As an example of a typical repair necessitating the removal of dents from a domed-shaped mudguard, the method of procedure is first to smooth the dents so far as possible with a suitable hammer or wooden mallet, preferably on a hardwood concave block Afterthe dents have been straightened out as well as possible, the mudguard can be smoothed up by placing it on iron blacks of different radii (the one that fits the mudguard curvature should be used) and hammering over and around the dented area. Careful, light • hammering will restore it to its original shape.

In removing a V-shaped dent, the metal just escaping perforation, sharp hammer blows should be avoided. It is generally best to anneal the sheet metal in the immediate vicinity of the damaged part (a petrol blow-lamp flame will be found useful for this) to minimize any possibility of cranking. The force of the blow that caused the sharp dent hardened the sheet metal at that point probably too much to withstand any more bumping dr hammering without annealing it. When this has been correctly clone, persistent and judicious hammering will force out the dent until the original oRntour is restored. Experience shows that it is very much better to deliver

50 blows to remove a dent than halfa-dozen sharp and. heavy ones whereby the metal is likely to become

stretched or cracked. "Gently does the trick.".

En dealing -with a number of small indentations that cannot be readily reached with the tools available, it is sometimes advisable to fill the dents up with soft solder (50 per cent. lead and 50 per cent. tin) and afterwards

file the solder smooth. The surface may afterwards be rubbed with emery cloth to take out the file marks.

The G.E. Denterazer, supplied by the Garage Equipment Co., Railway Street, Braintree, is an extremely use

ful appliance for removing dents from mudguards and wings, especially in situ.

Should soldering methods be employed for filling up dents, care must be taken thoroughly to wash off all traces of the soldering flux in order to • avoid subsequent corrosion of the metal,

An Improvised Drive for a Water Pump.

TnE drive to the water pump of a

• 5-ton Pierce-Arrow lorry appears to have given " W.T.M.," of Grantham, some trouble owing to the dogs wearing and clattering until one day they refused to drive at all. Our correspondent had to get home, so he procured a piece of three-ply radiator hose ; he then removed the dog-drivts shaft and replaced it with the hose, first placing a length of coil spring inside the hose to prevent it from collapsing while taking the drive. He suggests that this spring should be slightly longer than the space between the ends of the shafts so as to prevent rattle.

The water clips were of the type tightened by a worm. He tells us that these made a neat finish to the job.

A Device Which Helps When Adjusting Tappets.

A 'USEFUL device is described by a correspondent, " J.F.M.," of Luton. On some types of engine tappet adjustment is difficult, due to the fact that the tappets are themselves free to rotate. Generally, two flats are milled at the top of the tappet so that a spanner con be used to keep it from revolving.

As two other spanners are also re(mired, one to adjust the screw and the other for the lockrrut, it becomes almost a three-handed job.

This difficulty can be overcome by cuttine.' a piece of plate as shown in a sketch. The engine is turned until both valves of the required cylinder are closed.

The plate spanner is slipped on to both tappets, and then with the other two spanners adjustment can be made without having to bother about the rotation of the tappets.

A Thrust-bearing Tip.

ONE of our readers at Accrington (who has. omitted his name) tells us that, through lack of lubricant, he had trouble with the cape which holds the balls in place in the clutch-withdrawal gear of his J-type Thornycroft.

To introduce a new cage in the usual manuer would have meant several hours' work, as the gearbox would have had to be shifted. The cage in question appears to have been one of that type where the balls are separated by a ring made from sheet steel. Ele cut through the ring with a hacksaw and bent it in a sideways direction until he made a gap sufficiently wide -for it to be slipped over its shaft. When in place he straightened it, brought the races up to their original places and all was in working order.