SPRING SUSPENSIONS PRESENT AND FUTURE.

Page 45

Page 46

If you've noticed an error in this article please click here to report it so we can fix it.

A Continuation of an Article the First Part of which was Publisl.ed Last Week. Some More Types of Spring and Their Practicability for Heavy Vehicles. Considerations of Semi-bogie Construction.

THE OPENING part of this article appeared last week, and we should advise those readers who are about to -commence reading this portion first to go through the previous matter, which contains much of interest and value and gives an excellent idea of the difficulties which are encountered in providing efficient vehicle suspension and, at the same time, forms a review of modern practice.

At the conclusion of last week's portion we made reference to the charaeteristics of the quarter-elliptic spring, pointing out some of its advantages, and we now proceed to discuss some of its disadvantages.

It is very doubtful whether the quarter-elliptic spring will ever become really suitable for front-axle suspension. This can also be said to apply to the full cantilever type. The complication of the front axle, due to the need for making it capable of withstanding the torque reaction due to braking, has almost precluded any possibility of utilizing this form of springing in • its present form, whilst, in addition, the risk of spring • breakage might become a very serious matter unless • some form of safety device be evolved, which would, of course, add to the complication of the "ensemble."

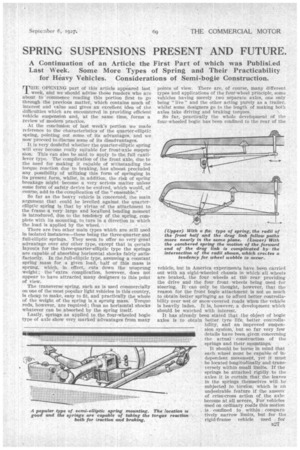

So far as the heavy vehicle is concerned, the main argument that could be levelled against the quarterelliptic spring is that by virtue of the attachment to the franie a very large and localized bending moment is introduced, due to the tendency of the spring, complete with its mounting, to turn in a direction in which the load is applied by the wheel.

There are two other main types which are still used in isolated instances—these being the three-quarter and full-elliptic springs. They seem to offer no very -great advantage over any other type, except that in certain layouts for the three-quarter-elliptic type the springs are capable of absorbing horizontal shocks fairly satisfactorily. In the full-elliPtic type, assuming a constant spring mass for a given load, half of this mass is sprung, which, in effect, cuts down the unsprung weight; the 'extra complication, however, does not appear to have attracted many designers to this point of view.

The transverse spring, such as is used commercially on one of the most popular light vehicles in this country, is cheap to make, easy to fit, and practically the whole of the weight of the spring is a sprung mass. Torque rods, however, are required; thus no horizontal shocks whatever can be absorbed by the spring itself.

Lastly, springs as applied to the four-wheeled bogie type of axle show very marked advantages from many points of view. There are, of course, many different types 'and applications of the four-wheel principle, some Vehicles having merely two separate axles, one only being " live " and the other acting purely as a trailer, whilst some designers go to the length of making both axles take driving and braking torques.

So far, practically the whole development of the four-wheeled bogie has been confined to the rear of the vehicle, but in America experiments have been carried out with an eight-wheeled chassis in which all wheels are braked, the four wheels at the rear providing the drive and -the four front wheels being used for steering. It can only be thought, however, that the reason for the front bogie attachment is not so much to obtain better springing as to afford better controllability over wet or snow-covered roads when the vehicle is heavily laden. It is, however, a development which should be watched with interest.

It has already been stated that the object of bogie axles is to obtain better tyre life, better controllability, and an improved suspension system," but so far very few details have been given concerning the actual construction of the springs and. their mountings.'

It should be borne in mind that each_ wheel must be . cabable of independent movement, yet it must be located longitudinally and-transversely within small limits. If the springs be attached rigidly to the axles it is certain that: the leaves in the springs .themselves will be subjected to torsion; which iszm undesirable', feature if the amoun of criss-cross action. of .the axle:

• become at all severe ForT vehicles used on ordinary roads this motion _ is 'confined to within comparatively narrow limits; but for the . rigid-frame vehicle used for B27

transporting heavy loads over undulating country the criss-cross action becomes so great at times that the plates would undoubtedly become strained—and in time broken—if no compensating mechanism Were included in the system. Although on the surface this compensation seems to be difficult of attainment, it is, in reality, comparatively simple. Usually, in a vehicle of this type the springs are duplicated and placed one above the other, the two being connected by a yoke, which is, in turn, attached to the frame. The springs, which are generally of the inverted, semi-elliptic type, are pivoted at their centres. In one type of compensated mounting trunnion brackets are bolted to the axle casings, with trunnions lying fore and aft on each axle. These brackets join up with horizontal pins passing through the ends of each of the spring eyes, so that they virtually provide universal joints between the springs and the axle casings.

In certain designs a difference of axle level of 12 ins. is allowed, whiLst when each axle is erisg:crossed oppositely a difference of 18 ins. in wheel level can occur. These figures are very big indeed, considering the comparatively small wheelbase between the forward and trailing axles of the bogie; consequently, if provision has not been made to relieve the springs of torsion, net only will the spring -be badly overstressed but the system will undoubtedly work somewhat irregularly. For normal road use there is no need to make any

such provision, because the amount of relative deflection is comparatively small_ By mounting two springs on a single trunnion the rocking motion is allowed, but the springs, and consequently the axles, are located laterally in a perfectly satisfactory manner, the location in actual practice being rather better than with a single semi-elliptic spring, which does, to all intents and purposes, provide a perfectly satisfactory form of location.. There are, of course, other forms of suspension for the four-wheeled bogie type, such as by employing two semi-elliptic springs in line with each other. The springs are located at the centre by a yoke, which allows relative movement between the two axles to take place. The system does not appear to be so simple and symmetrical as some of the types where the bogie is mounted on trunnion bearings, despite the fact that such a type has given excellent service on a number of six-wheeled buses run by a well-known concern in the Midlands.

In a concluding article of this series the trend of future developments will be reviewed. There are many systems of springing in the course of evolution which should lead eventually to definite advantages from the points of view of the user, designer and the public, and it is proposed to give prominence to some of the distinctive features of ideal forms of suspension and to see haw far they can be applied in practice.