PauIs'

Page 74

If you've noticed an error in this article please click here to report it so we can fix it.

PAULS MALT's buy-British policy was forsaken when it decided to purchase an extralight tipping semi-trailer.

Specified at 50cum (65.39 cuyd) capacity, ii was to be under 3.5m (lift 6in) high and less than 11.58m (38f1) long. However, a 25 tonne payload was also wanted, implying a triaxle trailer tare weight below 6.5 tonnes. This was to include a donkey engine to run at the specified load within 38 tonne gcw and coupled to a Seddon Atkinson 401 tractive unit.

LAG (UK) was the only trailer manufacturer which said it could meet the specification using aluminium alloy throughout. The result was a multi-national effort weighing in at 5.8 tonnes.

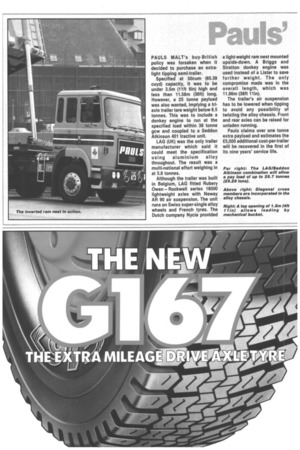

Although the trailer was built in Belgium, LAG fitted Rubery Owen — Rockwell series 18000 lightweight axles with Neway AR 90 air suspension. The unit runs on Swiss super-single alloy wheels and French tyres. The Dutch company Nycia provided a light-weight ram nest mounted upside-down. A Briggs and Stratton donkey engine was used instead of a Lister to save further weight. The only compromise made was in the overall length, which was 11.86m (38f1 11in).

The trailer's air suspension has to be lowered when tipping to avoid any possibility of twisting the alloy chassis. Front and rear axles can be raised for unladen running.

Pauls claims over one tonne extra payload and estimates the £5,000 additional cost-per-trailer will be recovered in the first of its nine years' service life.