Easy-maintenance middleweights

Page 134

Page 136

If you've noticed an error in this article please click here to report it so we can fix it.

ALL COMMERCIAL vehicle maufacturers in Western Europe are well aware that the acceptance of their products depends as much on the supporting service network as on the vehicles themselves.

Sharp-eyed fleet engineers, owneroperators and transport managers are quick to detect any shortcomings and the effect it will have on their business.

Mercedes Benz, too, recognises the value of an efficient support system and to that end has established a back-up service which is worldwide.

Its service dealers in Britain are well equipped and trained to carry out contractual and other maintenance and repairs. In support of the new middle-weight range, the company has prepared two sets of courses at its training school in Hayes. Middlesex, one for its own dealers' mechanics, the other for the operators' tradesmen. Both deal in depth with the new 0M364 and 0M366 engines, although the school has allowed for a great deal of flexibility. This is necessary to compensate for mechanics' different previous training and background.

For servicing Mercedes stipulates that only tested and recommended lubricants must be used. Where warranty claims are encountered oil samples are taken to ensure that they meet an agreed specification.

Engine oil and filter change frequency depends partly on the type of oil used. With SAE15 W40 multigrade oil at least once a year is recommended, otherwise at least twice a year is normal.

After the initial 500 to 1.500km (300-900 miles) service, oil change frequency also depends upon operating conditions and annual mileages. Intervals are extended if vehicles are covering more than 100,000km (60,000 miles) annually.

Greasing has been reduced to seven nipples on UK models, four on the front axle king pins and the remainder on thepropeller shafts. Despite a modern self-adjusting clutch Mercedes, still fits a grease cup to lubricate the release bearing.

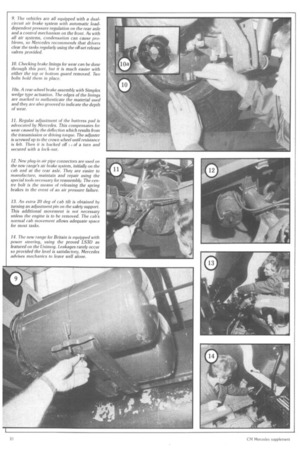

9. The vehicles are all equipped with a dualcircuit air brake system with automatic loaddependent pressure regulation on the rear axle and a control mechanism on the front. As with all air systems, condensation can cause problems, so Mercedes recommends that drivers clear the tanks regularly using the off-set release valves provided.

10. Checking brake linings for wear can be done through this port, but it is much easier with either the top or bottom guard removed. Two bolts hold them in place.

10a. A rear-wheel brake assembly with Simplex wedge type actuation. The edges of the linings are marked to authenticate the material used and they are also grooved to indicate the depth of wear.

11. Regular adjustment of the buttress pad is advocated by Mercedes. This compensates for wear caused by the deflection which results from the transmission or driving torque. The adjuster is screwed up to the crown wheel until resistance is felt. Then it is backed off 1 of a turn and secured with a lock-nut.

12. New plug-in air pipe connectors are used on the new range's air brake system, initially on the cab and at the rear axle. They are easier to manufacture, maintain and repair using the special tools necessary for reassembly. The centre bolt is the means of releasing the spring brakes in the event of an air pressure failure.

13. An extra 20 deg of cab tilt is obtained by turning an adjustment pin on the safety support. This additional movement is not necessary unless the engine is to be removed. The cab's normal cab movement allows adequate space for most tasks.

14. The new range for Britain is equipped with power steering, using the proved LS3D as featured on the Unimog. Leakages rarely occur so provided the level is satisfactory, Mercedes advises mechanics to leave well alone.