Securing the load

Page 52

Page 53

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

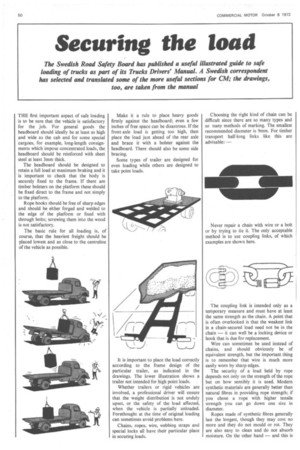

THE first important aspect of safe loading is to be sure that the vehicle is satisfactory for the job. For general goods the headboard should ideally be at least as high and wide as the cab and for some special cargoes, for example, long-length consignments which impose concentrated loads, the headboard should be reinforced with sheet steel at least 3mm thick.

The headboard should be designed to retain a full load at maximum braking and it is important to check that the body is securely fixed to the frame. If there are timber bolsters on the platform these should be fixed direct to the frame and not simply to the platform.

Rope hooks should be free of sharp edges and should be either forged and welded to the edge of the platform or fixed with through bolts; screwing them into the wood is not satisfactory.

The basic rule for all loading is, of course, that the heaviest freight should be placed lowest and as close to the centreline of the vehicle as possible. Make it a rule to place heavy goods firmly against the headboard; even a few inches of free space can be disastrous. If the front-axle load is getting too high, then place the load just ahead of the rear axle and brace it with a bolster against the headboard. There should also be some side bracing.

Some types of trailer are designed for even loading while others are designed to take point loads.

It is important to place the load correctly according to the frame design of the particular trailer, as indicated in the drawings. The lower illustration shows a trailer not intended for high point loads.

Whether trailers or rigid vehicles are involved, a professional driver will ensure that the weight distribution is not unduly upset, or the safety of the load affected, when the vehicle is partially unloaded. Forethought at the time of original loading can sometimes avoid problems here.

Chains, ropes, wire, webbing straps and special locks all have their particular place in securing loads.

Choosing the right kind of chain can be difficult since there are so many types and so -nany methods of marking. The smallest recommended diameter is 9mm. For timber transport half-long links like this are advisable: —

Never repair a chain with wire or a bolt or by trying to tie it. The only acceptable method is to use coupling links, of which examples are shown here.

The coupling link is intended only as a temporary measure and must have at least the same strength as the chain. A point that is often overlooked is that the weakest link in a chain-secured load need not be in the chain — it can well be a locking device or hook that is due for replacement.

Wire can sometimes be used instead of chains, and should obviously be of equivalent strength, but the important thing is to remember that wire is much more easily worn by sharp edges.

The security of a load held by rope depends not only on the strength of the rope but on how sensibly it is used. Modern synthetic materials are generally better than natural fibres in providing rope strength; if you chose a rope with higher tensile strength you can go down one size in diameter.

Ropes made of synthetic fibres generally last the longest, though they may cost no more and they do not mould or rot. They are also easy to clean and do not absorb moisture. On the other hand — and this is not sufficiently well known — they can suffer a degree of deterioration by being stored in sunlight for a long time; they are also sensitive to cold and certain kinds of chemicals.

A high degree of tensile strength is not the same thing as good resistance to wear: some synthetic fibres wear very easily and must be protected at sharp edges. Ropes of synthetic fibre are more elastic than those made of natural fibre. Sometimes this is an advantage (they do not have to be tightened so often). Sometimes this is a disadvantage (the load can move about).

Webbing bands — or stretch bands as we sometimes call them — can be excellent securing devices, especially with boxed and cartoned goods. They are also becoming used more widely for securing building materials such as building blocks. Since there is no uniform marking of these bands it is important to know the strength of each type and grade, and to protect them against sharp edges.

A strong chain will not do its job unless it is properly tightened on the load. A good snug fit, using a reliable tensioner, will produce a result like this, for example:

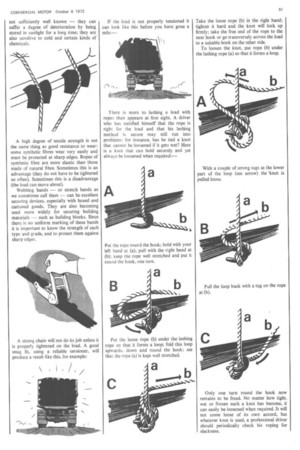

If the load is not properly tensioned it can look like this before you have gone a mile:— There is more to lashing a load with ropes than appears at first sight. A driver who has satisfied himself that the rope is right for the load and that his lashing method is secure may still run into problems: for instance, has he tied a knot that cannot be loosened if it gets wet? Here is a knot that can hold securely and yet always be loosened when required:—

Put the rope round the hook; hold with your left hand at (a); pull with the right hand at (b); keep the rope well stretched and put it round the hook, one turn.

Put the loose rope (b) under the lashing rope so that it forms a loop; fold this loop upwards, down and round the hook; see that the rope (a) is kept well stretched. Take the loose rope (b) in the right hand; tighten it hard and the knot will lock up firmly; take the free end of the rope to the next hook or go transversely across the load to a suitable hook on the other side.

To loosen the knot, put rope (b) under the lashing rope (a) so that it forms a loop.

With a couple of strong tugs at the lower part of the loop (see arrow) the 'knot is pulled loose.

Pull the loop back with a tug on the rope at (b).

Only one turn round the hook now remains to be freed. No matter how tight, wet or frozen such a knot has become, it can easily be loosened when required. It will not come loose of its own accord, but whatever knot is used, a professional driver should periodically check his roping for slackness. A tarpaulin sheet is intended primarily to protect the load from dust and damp, and not to support it. The load should be secured before sheeting commences.

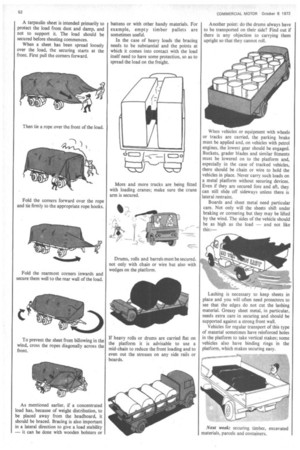

When a sheet has been spread loosely over the load, the securing starts at the front. First pull the corners forward.

As mentioned earlier, if a concentrated load has, because of weight distribution, to be placed away from the headboard, it should be braced. Bracing is also important in a lateral direction to give a load stability — it can be done with wooden bolsters or battens or with other handy materials. For example, empty timber pallets are sometimes useful.

In the case of heavy loads the bracing needs to be substantial and the points at which it comes into contact with the load itself need to have some protection, so as to spread the load on the freight.

If heavy rolls or drums are carried flat on the platform it is advisable to use a mid-chain to reduce the front loading and to even out the stresses on any side rails or boards. Another point: do the drums always have to be transported on their side? Find out if there is any objection to carrying them upright so that they cannot roll.

When vehicles or equipment with wheels or tracks are carried, the parking brake must be applied and, on vehicles with petrol engines, the lowest gear should be engaged. Buckets, grader blades and similar fitments must be lowered on to the platform and, especially in the case of tracked vehicles, there should be chain or wire to hold the vehicles in place. Never carry such loads on a metal platform without securing devices. Even if they are secured fore and aft, they can still slide off sideways unless there is lateral restraint.

Boards and sheet metal need particular care. Not only will the sheets shift under braking or cornering but they may be lifted by the wind. The sides of the vehicle should be as high as the load — and not like this:—

Lashing is necessary to keep sheets in place and you will often need protectors to see that the edges do not cut the lashing material. Greasy sheet metal, in particular, needs extra care in securing and should be supported against a strong front wall.

Vehicles for regular transport of this type of material sometimes have reinforced holes in the platform to take vertical stakes; some vehicles also have binding rings in the platform, which makes securing easy.