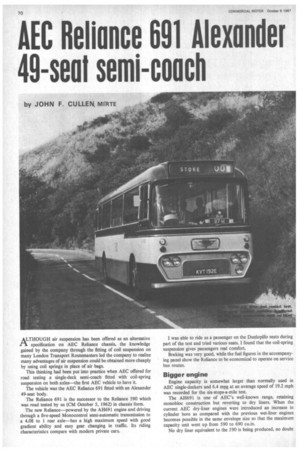

AEC Reliance 691 Alexander 49-seat semi-coach

Page 72

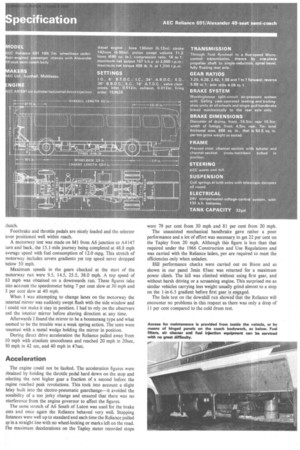

Page 73

Page 77

Page 78

If you've noticed an error in this article please click here to report it so we can fix it.

by JOHN F. CULLEN, MIATE

ATHOUGH air suspension has been offered as an alternative specification on AEC Reliance chassis, the knowledge gained by the company through the fitting of coil suspension on many London Transport Routemasters led the company to realize many advantages of air suspension could be obtained more cheaply by using coil springs in place of air bags.

This thinking had been put into practice when AEC offered for road testing a single-deck semi-coach fitted with coil-spring suspension on both axles—the first AEC vehicle to have it.

The vehicle was the AEC Reliance 691 fitted with an Alexander 49-scat body.

The Reliance 691 is the successor to the Reliance 590 which was road tested by us (CM October 5, 1962) in chassis form.

The new Reliance—powered by the AH691 engine and driving through a five-speed Monocontrol semi-automatic transmission to a 4.08 to 1 rear axle—has a high maximum speed with good gradient ability and easy gear changing in traffic. Its riding characteristics compare with modern private cars. I was able to ride as a passenger on the Dunlopillo seats during part of the test and tried various seats. I found that the coil-spring suspension gives passengers real comfort.

Braking was very good, while the fuel figures in the accompanying panel show the Reliance to be economical to operate on service bus routes.

Bigger engine

Engine capacity is somewhat larger than normally used in AEC single-deckers and 6.4 mpg at an average speed of 19.2 mph was recorded for the six-stops-a-mile test.

The AH691 is one of AEC's well-known range, retaining monobloe construction but reverting to dry liners. When the current AEC dry-liner engines were introduced an increase in cylinder bore as compared with the previous wet-liner engines becomes possible in the same envelope size so that the maximum capacity unit went up from 590 to 690 cu.in.

No dry liner equivalent to the 590 is being produced, no doubt because the goods-vehicle demand has swung over to more powerful engines.

As an alternative for operation where the advantage of a large-capacity power unit operating at a rather lower governed speed is not so apparent, the Reliance 505 is available.

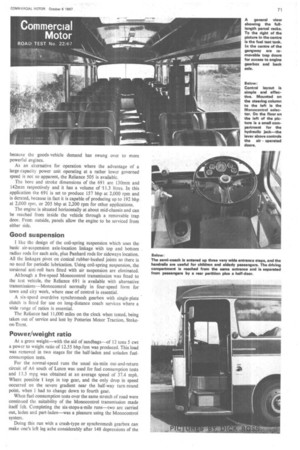

The bore and stroke dimensions of the 691 are 130mm and 142mm respectively and it has a volume of '11.3 litres. In this application the 691 is set to produce 157 bhp at 2,000 rpm and is derated, because in fact it is capable of producing up to 192 bhp at 2,000 rpm, or 205 bhp at 2,200 rpm for other applications.

The engine is situated horizontally at about mid-chassis and can be reached from inside the vehicle through a removable trap door. From outside, panels allow the engine to be serviced from either side.

Good suspension

I like the design of the coil-spring suspension which uses the basic air-suspension axle-location linkage with top and bottom radius rods for each axle, plus Panhard rods for sideways location. All the linkages pivot on Conical rubber-bushed joints so there is no need for periodic lubrication. Using coil-spring suspension, the torsional anti-roll bars fitted with air suspension are eliminated.

Although a five-speed Monocontrol transmission was fitted to the test vehicle, the Reliance 691 is available with alternative transmissions—Monocontrol normally in four-speed form for town and city work, where ease of control is essential.

A six-speed overdrive synchromesh gearbox with single-plate clutch is fitted for use on long-distance coach services where a wide range of ratios is essential.

The Reliance had 11,000 miles on the clock when tested, being taken out of service and lent by Potteries Motor Traction, Stokeon-Trent.

Power/weight ratio

At a gross weight—with the aid of sandbags—of 12 tons 5 cwt a power to weight ratio of 12.55 bhp /ton was produced. This load was removed in two stages for the half-laden and unladen fuelconsumption tests.

For the normal-speed runs the usual six-mile out-and-return circuit of Ab south of Luton was used for fuel consumption tests and 13.3 mpg was obtained at an average speed of 37.4 mph. Where possible I kept in top gear, and the only drop in speed occurred on the severe gradient near the half-way turn-round point. when I had to change down to fourth gear.

When fuel-consumption tests over the same stretch of road were continued the suitability of the Monocontrol transmission made itself felt. Completing the six-stops-a-mile runs—two are carried out, laden and part-laden—was a pleasure using the Monocontrol system.

Doing this run with a crash-type or synchromesh gearbox can make one's left leg ache considerably after 148 depressions of the clutch.

Footbrake and throttle pedals are nicely loaded and the selector Lever positioned well within reach.

A motorway test was made on M1 from A6 junction to A4147 turn and back, the 15.1-mile journey being completed at 48.8 mph average speed with fuel consumption of 12.0 mpg. This stretch of motorway includes severe gradients yet top speed never dropped below 50 mph.

Maximum speeds in the gears checked at the start of the motorway run were 9.5, 14.5, 25.5, 38.0 mph. A top speed of 63 mph was obtained on a downwards run. These figures take into account the speedometer being 7 per cent slow at 30 mph and 3 per cent slow at 40 mph.

When 1 was attempting to change lanes on the motorway the !xternal mirror was suddenly swept flush with the side window and [ could not make it stay in position. I had to rely on the observers Ind the interior mirror before altering direction at any time.

Afterwards I found the mirror to be a boomerang type and what ;eemed to be the trouble was a weak spring action. The tests were resumed with a metal wedge holding the mirror in position.

During direct drive acceleration the Reliance pulled away from 10 mph with absolute smoothness and reached 20 mph in 20sec, 30 mph in 42 sec, and 40 mph in 47sec.

Acceleration

The engine could not be faulted. The acceleration figures were )btained by holding the throttle pedal hard down on the stop and ;electing the next higher gear a fraction of a second before the mgine reached peak revolutions. This took into account a slight ielay built into the electro-pneumatic gearchange—it avoided the Dossibility of a too jerky change and ensured that there was no nterference from the engine governor to affect the figures.

The same stretch of A6 South of Luton was used for the brake :ests and once again the Reliance behaved very well. Stopping iistances were well up to standard and each time the Reliance pulled ip in a straight line with no wheel-locking or marks left on the road. The maximum decelerations on the Tapley meter recorded stops were 79 per cent from 30 mph and 81 per cent from 20 mph.

The unassisted mechanical handbrake gave rather a poor performance and a lot of effort was necessary to get 22 per cent on the Tapley from 20 mph. Although this figure is less than that required under the 1966 Construction and Use Regulations and was carried with the Reliance laden, psv are required to meet the efficiencies only when unladen.

Hill performance checks were carried out on Bison and as shown in our panel 3min 85sec was returned for a maximum power climb. The hill was climbed without using first gear, and without harsh driving or a screaming engine. This surprised me as similar vehicles carrying less weight usually grind almost to a stop on the 1-in-6.5 gradient before first gear is engaged.

The fade test on the downhill run showed that the Reliance will encounter no problems in this respect as there was only a drop of 11 per cent compared to the cold drum test. When a stop was made on the 1-in-6.5 gradient the Reliance would not move off in second gear, but pulled away quite happily in first. The handbrake held comfortably whichever way the Reliance faced. It reversed effortlessly up the hill.

The driving position offers a good view through the large onepiece windscreen, which added to the forward visibility of 7ft makes a good contribution towards road safety. The driver's seat is reached by the three entrance steps and is separated from the passengers' compartment by a half-door.

Transmission

Semi-automatic transmission based on the Self-Changing Gears basic design is becoming common on passenger vehicles and makes driving a pleasure. The AEC Monocontrol version fitted to the Reliance has the usual CAV control switch mounted on an arm on the steering column.

Engine noise was relatively low within the vehicle. Steering (the AEC worm and nut type) was very satisfactory, except at times at roundabouts or sharp bends when a lock had to be put on. The column-mounted instruments are easy to read with switches for lights, trafficators, etc., mounted under the offside front window quite close to the driver's right hand. The seating is arranged for 49 passengers and gives me my only clue as to why this vehicle is termed a semi-coach-from the outside it resembles a single-decker bus but it has the interior finish of a coach.

The seating layout is fairly generously spaced and I noticed an absence of stanchions. Handrails are fitted on the rear of the back rest and along the full length of the interior are two large capacity parcel racks. Interior artificial lighting is provided by three strip lights, and three opal perspex roof vents open for fresh air. Other ventilation is provided through intakes in the front dome directly above the windscreen on either side. No opening windows are provided.

The two entrance doors, of the Petters air-operated Giyder type, are controlled by the driver. On the two days' test, with a fair amount of high wind about, the interior was kept free of draughts by a brush type draught excluder around the door openings.

Twin headlamps are provided, with directional indicators and side-lights mounted immediately above. There is a large luggage boot at the rear. It is reached by a horizontally hinged fibreglass door.