LOCK ACTUATOR

Page 64

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

or SPRING BRAKE?

A braking-equipment maker assesses the relative merits.

By P. A. C. Brockington, AMIMechE

Mt-1E relative merits of the lock actuator and spring brake, and whether the use of either could be dispensed with by employing a power-assisted handbrake, are an immediate concern of makers of braking equipment.

At the moment most operators will readily accept any system that provides satisfactory braking; but developments and applications in the very near future will launch trends which will influence design standards.

Braking equipment makers' views on the subject are of special interest, and Clayton Dewandre is one manufacturer with something relevant to say.

This company points out that a conventional power-assisted handbrake acting on the driving axle of an articulated vehicle may not provide sufficient parking-brake performance to satisfy the Code of Practice —because of the limited adhesion afforded by two wheels. Otherwise it would represent the simplest and cheapest method to use, in conjunction with service and secondary brakes based on doubleor triple

diaphragm actuators.

In general, it will be necessary to apply a parking brake to the front axle as well as the driving axle of heavier tractive units, and this can best be done with a lockactuator or spring brake because mechanical linkage is undesirable. In practice, one or the other will commonly be used for both axles and will also be applied to rigid vehicles. Each has relative advantages, says Clayton Dewandre; initially the choice will be made by vehicle manufacturers, but later the decision may well be influenced by operators' opinions.

A spring brake releases its energy in the event of air-pressure failure, and this is regarded as an outstanding advantage by some vehicle makers and users. Clayton Dewandre points out that air failure could, however, occur when the vehicle was travelling at speed in traffic and the resultant sudden braking could be highly dangerous. Moreover, in the event of fire at a depot, it might be impossible to move a vehicle fitted with spring brakes if the engine could not be started. Over a period air leakage would automatically apply the brakes of a vehicic with its brakes left off.

A lock actuator is relatively light and car easily be applied to any type of diaphragrr or piston-diaphragm actuator, says Clayton Although it is impossible to apply the brakt in the event of air-pressure failure, its us( does not involve the danger of self application. Lock actuators produced b3 Clayton Dewandre are of Bendix Westinghouse design.

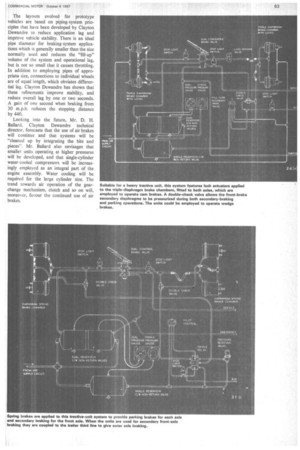

Built under licence to the Gustin Bacot company of America, the spring brake: are of the Maxibrake type, in which tit( diaphragm is located on the outside tc provide easy removal; location of the sprinl on the inside facilitates stable mounting, b3 virtue of the weight concentration it afford relatively close to the mounting studs. Thl spring force can be employed for parkini only, or for both parking and secondary brake application.

When it is used as a secondary brake, till release of air from the piston chamber i graduated by movement of the hand leve according to the braking force required. The layouts evolved for prototype vehicles are based on piping-system principles that have been developed by Clayton Dewandre to reduce application lag and improve vehicle stability. There is an ideal pipe diameter for braking-system applications which is generally smaller than the size normally used and reduces the "fill-up" volume of the system and operational lag, but is not so small that it causes throttling. In addition to employing pipes of appropriate size, connections to individual wheels are of equal length, which obviates differential lag. Clayton Dewandre has shown that these refinements improve stability, and reduce overall lag by one or two seconds. A gain of one second when braking from 30 m.p.h. reduces the stopping distance by 44ft.

Looking into the future, Mr. D. H. Ballard, Clayton Dewandre technical director, forecasts that the use of air brakes will continue and that systems will be "cleaned up by integrating the bits and pieces". Mr. Ballard also envisages that smaller units operating at higher pressures will be developed, and that single-cylinder water-cooled compressors will be increasingly employed as an integral part of the engine assembly. Water cooling will be required for the large cylinder size. The trend towards air operation of the gearchange mechanism, clutch and so on will, moreover, favour the continued use of air brakes.