IMPROVEMENTS IN REAR AXLE CONSTRUCTION.

Page 32

If you've noticed an error in this article please click here to report it so we can fix it.

A Resume of Recently Published Patent Specifications.

THE ideal of the perfect rear axle has not yet been reached. All the types in use to-day have their good and bad points. The pinion and rack ring type has, like other types, certain features which commend it, whilst certain defects seem to be inseparable from this form of axle and drive, as we have known them in the past. The engineers of the London General Omnibus Co., however, seem to have made great strides in their adaptation of this form of drive, and we believe they will go further. The specification of Jacques Gerin, of Paris, No. 226,542 shows a somewhat new application of the rack

• ring and pinion.

In the present invention, the shaft which carries the pinion is borne by a bearing which is rigidly attached to the chassis frame. Upon the boss of this bearing is mounted a strong lever, which can swing on the boss as a bearing. At the end of this lever farthest from the boss is mounted a stub axle which carries the wheel. These levers obviously lie in a horizontal position, otherwise the spring action could not take place, although the specification describes them as being situated vertically.

Each of the levers is provided with a spring, and it will be seen that as the springs give to the unevenness of the road, the lever will pivot around the axis of the pinion, and so the latter will be always in correct mesh with the rack ring. The drawing is, of course, merely (Ungrammatical, and no particular arrangement is shown for attaching the springs, which might be arranged at either the stub axle end of the lever, or could be mounted on an extension of the lever where shown broken off.

Improvements in the Manufacture of Fuel Similar to Petrol

AN improved process for manufac turing a liquid fuel having the general characteristics of petrol or benzol, is described in specification No. 238,921 by Eugene Prudhomme, of Antibes, France. The process described consists (1) of adding gases rich in hydrocarbons to water gas or Dowson gas issuing from a gas producer, such rich gases being of the acetylene series ; and (2) in passing a complex gas mixture thus obtained over a hydrogenation catalyst, then over a dehydronation catalyst and finally a special form of catalyst, which is described, to effect polymerisation of the acetylene hydrocarbon's. The process is one in which the solid fuel submitted to a low-temperature process of distillation under the action of the current of hot gas is a lignite or peat, such lignite or peat leaving after distillation a kind of wood charcoal, which can be readily gasified in a gas generator in order to pass the gas so produced through fresh masses of lignite or peat to be distilled.

An Improvement in Brake Construction.

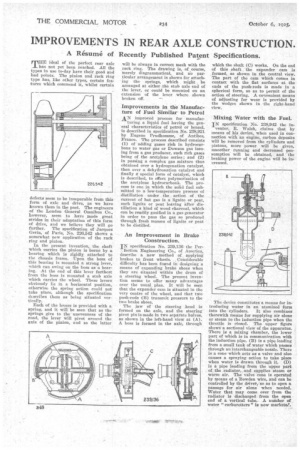

IN specification No. 239.136 the Per

fection Engineering Co., of America, describe a new method of applying brakes to front wheels. Considerable difficulty has been foltnd in designing a means of expanding brake shoes when they are situated within the drum of a steering wheel. The present invention seems to offer many advantages over the usual plan. It will be seen that the expander cam is situated in the very centre of the wheel, and that two push-rods (B) transmit pressure to the two brake shoes.

The jaw of the steering head is formed on the axle, and the steering pivot pin is made in two separate halves, as shown in the left-hand view at (A). A boss is formed in the axle, through

which the shaft (C) works. On the end of this shaft the expander cam is formed, as shown in the central view. The part of the cam which comes in contact with the fiat surfaces at the ends of the push-rods is made in a spherical form, so as to permit of the action of steering. A couvenient means of adjusting for wear is provided by the wedges shown in -the right-hand view.

Mixing Water with the Fuel.

IN specification No. 238,942 the in ventor, R. Walsh, claims that by means of his device, when used in connection with an engine, carbon deposits will be removed from the cylinders and pistons, more power will be given, smoother running and decreased consumption will be obtained, and the braking power of the engine will be increased.

The device constitutes a means for introducing water in an atomized form

into the cylinders. It also combines therewith means for supplying air alone or steam to the induction pipe when the throttle is closed. The upper figure shows a sectional view of the apparatus. There is a mixing chamber, the lower part of which is in communication with the induction pipe. (B) is a pipe leading from a small tank of water which passes through an interchangeable nozzle. There is a cone which acts as a valve and also causes a spraying action to take place when water is drawn through it. (D) is a pipe leading from the upper part of the radiator, and supplies steam or warm air. The valve cone is operated by means of a Rowden wire, and can be controlled by the driver, so as to open a passage for air alone when needed. Water that may come over from the radiator is discharged from the open end of a vertical tube. A number of water " carburetters " is now marketej.