MAKING BEST USE OF• THE• FORD.

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport, Which will Appeal to• the Owner, Driver and Repairer.

IN THIS series of hints concern_Ling the Ford light chassis and ton truck, we endeavour to deal with the subject from every viewpoint, so that the advice will appeal to the owner, driver, maintenance engineer or mechanic.

We shall welcome for inclusion amon:g the hints those which have proved of value to individual users, and will make suitable remuneration for any which are published.

349.—Troubles with the Firstspeed Band.

Continued neglect to adjust the firstspeed band may cause trouble. If the pedal travels too far forward the moving cam on the slow-speed shaft may come out of engagement with „the stationary cam mounted on the side of the transmission cover. It will then jam and hold the first speed in engagement, which in traffic may lead to accident

Failure of the slow speed is some times due to a cracked drum. The cracking is sometimes due to weakening of the drum caused by excessive wear on it, and in this connection it should be noted that the makers deprecate the employment of wire-woven bands. Their own bands are not even bonded.

350.—Doubling the Cooling Fan.

The ermines on some vehicles become overheated in a very short space of time, particularly in hot weather, with the result that boiling of the water in the radiator occurs; even if this be not the case, the radiator requires constant replenishment, To overcome the difficulty, the introduction of a double fan is suggested, and to make this, four blades, exact duplicates of those already in use, should be obtained. The rivets holdingthe first set of fan blades should be removed and replaced by longer ones, and the additional blades are then riveted jointly with the original set, but on the opposite side of the arms reaching from the fan huh. 'By bending the blades, each pair should have its units separated until they are about 14 ins, apart, thus greatly increasing the efficiency of the fan.

351.—Economizing Fuel on the Ton Truck.

One purchaser of a ton truck fund that when it was new he was only ohtaming eight or nine miles to the gallon. He 'thought that the mileage should be greater than this, and eventually fitted an extra air pipe from under the steering wheel, along the steering

column to the fillet pipe, this being"controlled by a tap under the steering wheel. This means brought the mileage per gallon up to an average lying between 12 and 14, this being qnite good, especially in the hilly districts of Cornwall where the vehicle was employed.

Later, he was asked to try a new piston ring called the "Three-in-One " ring, which, it was claimed, would increase the mileage. Twelve of these rings were used, and with these, it should be noted, a very fine gap is needed, as there are three slots to allow for expansion, there being an inner ring with grooves to act as guides for the two outer rings, slots in which are opposite, and the rings being pinned to avoid movement. With these rings the petrol consumption was reduced to a gallon per 20. miles, and, apart Irons this, there was a considerable saving in oil. These rings can be obtained from II. S. Hatch, 5, Worthy Lane, Winchester.

352.—A Worm-driven Magneto Conversion.

Although the ignition system employed on the Ford is simple and generally quite efficient, it is somewhat unusual, and certain users prefer to employ a more conirentional h.t. magneto.

For this there is a number of Conversion devices on the market. One of the best amongst these is the Apson wormdrive magneto conversion marketed by the London Magneto Repairing and Winding Co., Ltd., 78, Hampstead Road, London, N.W.I. This is designed to take practically any malee-of magneto with a centre height of 45 mm. It has machine-cut gearing and, when fitted, forms an actual component of the engine.

To install it the existing timing case is replaced by a new oil-tight casting, of which the magneto bracket and driving-shaft housing form an integral part The driving gears are totally enclosed and lubricated from the crankcase, and the driving spiral is screwed on to the end of the existing camshaft, where it is locked to prevent any possibility of loosening in the ease of a back-fire. The spiral engages with a pinion on the magneto driving shaft, the end thrust being taken up by an adjustable ball bearing. A valuable feature is the improved Watford vernier coupling, which is flexible, and makes possible easy and fine adjustment of the timing..

The set retails at £3 15s., including the coupling, but, of course, without the magneto. It can be supplied for either clockwise or anti-clockwise magnetos.

353.—Removing Steering Arm Bushes.

A practical reader points out that he finds the best method of removing the bushee from the steering arms is to make a saw-cut opposite the joint of each bush and to use an old brake or transmission band -spindle as a drift, this exactly fitting the steering arm bush. Once the bush is removed it is an easy matter to fit a new one, using the bench vice as a press.'

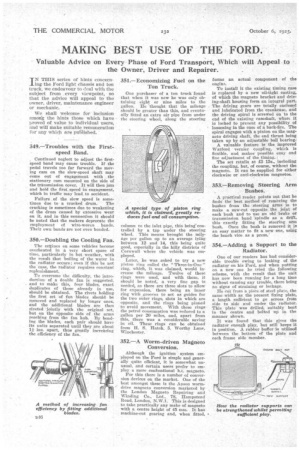

354.—Adding a Support to the Radiator.

One of our readers has had considerable trouble owing to leaking of the radiator on his Ford, and when putting on a new one he tried the following scheme, with the result that the unit has now been running for a long time without causing any trouble, there being no signs of straining or leakage.

He cut from a piece of steel plate, the same width as the present fixing plate, a length sufficient to go across from side to side and under the radiator. This plate was drilled, suitably bent in the centre and bolted up in the manner shown.

It was found that this gives the radiator enough play, but still keeps it in position. A rubber buffer is utilized between the bottom of the plate and each frame side member.