MEETING MODERN P ER-VEHICLE NEEDS.

Page 16

Page 17

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

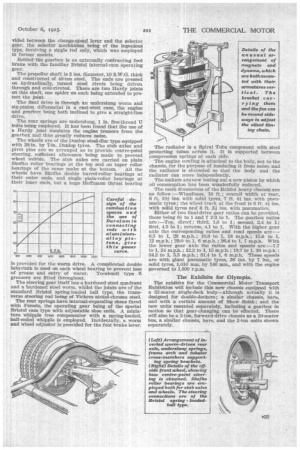

TN DEVELOPING their latest chassis for passenger .vehicles the Bristol Tramways and Carriage Co., Ltd., have adopted a principle which has been advocated by The Commercial Motor for many years. This is to design such chassis without any consideration for .their capacity or suitability as goods-carrying vehicles, constructing them solely from the point of view of the greatest efficiency in passenger transportation. For this reason the chassis—there will eventunlly be two, a heavy and a light, but at present we shall deal with the heavy only—will not be known by their carrying capacity, but merely as heavy and light passenger chassis, the first being suitable for doubledeck buses seating up to 60 persons and the second for single-deck buses with a. seating capacity up to 32.

There is little doubt that this divergence of the passenger vehicle from that designed purely for goods carrying will be more and more accentuated as time goes on. It is too much to expect that a chassis de'signed for the carrying of heavy dead loads should be equally satisfactory when used with live loads and often run at much higher speeds. It may be possible satisfactorily to employ a passenger vehicle for loadcarrying, but the converse seldom holds good.

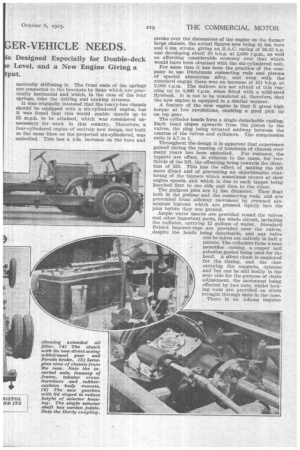

In the Bristol heavy passenger chassis there is an entirely new engine, a modified clutch, and a new gearbox, whilst the rear axle closely resembles that used on the former Bristol bus chassis, but is inverted so that the worm is carried underneath. The frame is also new. Its side members are horizontal until the rear axle, over which they are arched and then carried horizontally at a level 4 ins, below that of the forward portion, thus providing a low platform for the rear entrance. The actual frame level is 2 ft. 1 in. so far as the arch and 1 ft. 9 ins, at the rear of it.

Following latest Bristol practice, provision is made for carrying the body on sound-deadening and shockinsulating rubber cushions, there being eight double rubbers to take the load and rebound, these being carried by frame brackets, and six single compression cushions mounted on the spring brackets.

An interesting feature is the extension of the front cross-member of the frame to form brackets for the front cushions, with centres 5 ft. apart, thus affording adequate -support to the body.

The frame side-members have a maximum depth of 10 ins, and a width of 3 ins., the material em ployed being in. Vickers nickel steel. There are pressed-steel crossmembers at each end, and three tubular cross-members of 5i ins. diameter pressed by hydraulic means into steel brackets for attachment to the frame and riveted to these brackets by mild steel rivets driven in. It is interesting to note that these three cross-members together weigh practically the same as the single main cross-member on the 4-ton model. The side-members are inswept towards the engine, the frame width being 3 ft. 31 ins. before the sweep and 2 ft. 8 ins. after.

The body height is 5 ins, above the frame, giving a platform height of 2 ft. 6 ins.

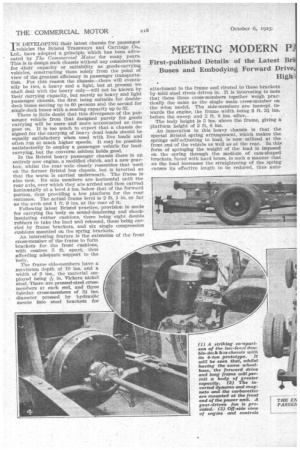

An innovation in this heavy chassis is that the special Bristol spring arrangement, which makes the springs self-adjusting to load, is now, utilized at the front end of the vehicle as well as at the rear. In this form of springing the weight of the load is imposed on the spring through the medium of cam-shaped brackets, faced with hard brass, in such a manner that as the load increases the straightening of the spring causes its effective length to be reduced, thus auto

matically stiffening it. The front ends of the springs are connected to the brackets by links which are practically horizontal and which, in the case of the rear springs, take the driving and braking stresses.

It was originally intended that the heavy-bus chassis should be equipped with a six-cylindered engine, but it was found that this would enable speeds up to 55 m.p.h. to be attained, which was considered -unnecessary for work in this country. Therefore, a four-cylindered engine of entirely new design, but built on the same lines as the projected six-cylindered, was embodied. This has a fin, increase on the bore and

stroke over the dimensions of the engine on the former large chassis, the actual figures now being 41 ins, bore and 6 ins, stroke, giving an R.A.C. rating of 36.15 h.p. and developing about 80 b.h.p. at 2,000 r.p.m., as well as affording considerable economy over that which would have been obtained with the six-cylindered unit.

For some time it has been the practice of the company to use Duralumin connecting rods and pistons of special aluminium alloy, and even with the standard engine there was an increase of 12i b.h.p. at 2,000 r.p.m. The makers are not afraid of this running up to 3,000 r.p.m. when fitted with a mild-steel flywheel. It is not to be wondered at, therefore, that the new engine is equipped in a similar manner.

A feature of the new engine is that it gives high torque at low revolutions, enabling a good pick up on top gear.

The cylinder heads form a single detachable casting. Each head slopes upwards from the piston to the valves, the plug being situated midway between the centres of the valves and cylinders. The compression ratio is 4.7 to 1.

Throughout the design it is apparent that experience gained during the running of hundreds of chassis over many years has been embodied. For instance, the tappets are offset, in relation to the cams, for twothirds of the lift, the offsetting being towards the direction of lift. This has the effect of making the lift more direct and of preventing an objectionable chattering of the tappets which sometimes occurs at slow engine speeds, and which is due to each tappet being knocked first to one side and then to the other.

The gudgeon pins are 1i ins. diameter. They float both in the pistons and the connecting rods, and are prevented from sideway movement by crowned aluminium buttons which are pressed tightly into the pins before they are ground.

Ample water spaces are provided round the valves and other important parts, the whole circuit, including the radiator, carrying 12 gallons of water. Standard Bristol bayonet-caps are provided over the valves, ,despite the heads being detachable, and any valve can he taken out entirely in half a minute. The cylinders form a neat monobloc casting, a copper and asbestos gasket being used for the head. A silent chain is employed for the timing, and the case carrying the magneto, dynamo and fan can be slid bodily to the near side for the purpose of chain adjustment, the movement being effected by two nuts, whilst locking nuts are provided on studs brought through slots in the case. starter on the magneto, which is also driven through a Hardy flexible coupling. Both the Simms magneto and the Smith dynamo are mounted vertically.

Thermo-siphonic circulation is employed for the cooling water, the conduits being 3* ins, bore throughout.

Great attention has been paid to adequate lubrication. There are no small holes anywhere, as trouble was formerly occasionally experienced through such holes, in the gallery supplying the troughs, blocking and causing big-end failure.

In the new system a submerged pump of the gear type delivers the whole of its output to one large conduit supplying oil under pressure to all the main and camshaft bearings. This conduit consists of a steel tube with cleaning plugs at each end, and all the passages are straight. A pipe at one end takes the oil to the timing case from which it runs back across the dipper troughs to strainers. The big-ends are lubricated solely from the dippers, thus avoiding loss of pressure when the big-ends wear.

It is intended that the strainer should never be touched except when the sump is removed, and to permit this there are 110 sq. ins, of strainer surface. All new oil is filtered through a separate strainer in the oil inlet, and access to this strainer can only be obtained by removing two nuts, so that the driver is not tempted to punch holes in it, as sometimes occurs when the strainer is within ready reach.

The valve-operating gear is constantly oiled, the lubricant draining back into the sump. A float is provided for indicating the oil level, and the oil filler is unusually high to render it more accessible.

Cooling is assisted by a fan driven from the timing chain through the medium of a Ferodo friction clutch.

The carburetter is mounted very high, and is bolted to the front end of the cylinder casting. This has been found neceSsary to keep it out of the way of dirt and dust, and to provide accessibility.

The whole unit presents a very clean appearance, particularly on the near side. It is four-point mounted in the chassis, but at the front end a certain amount of flexibility is afforded by utilizing a stout compression spring on each of the fixing bolts.

The successful Bristol clutch with a steel disc carried between two rings of friction material is retained, but it has been modified to permit direct withdrawal instead of using the three toggles formerly employed, for the reason that cases occurred of users finding difficulty in adjusting the three toggles uniformly. The adjustment is now by a simple thumb nut.

A ball-thrust bearing has been provided at the front end of the countershaft to take up counter thrust when the clutch is held out. A 1-16 in. movement of the clutch is sufficient entirely to free it ; further movement brings a Ferodo clutch brake into action. This clutch is one of the lightest to operate which we have ever tested, and compares favourably with those on many private ears.

The clutch plate is 17* ins, diameter and k in. thick. It has I in. radial cuts running to drilled holes near the centre, the design permitting the clutch to run almost red-hot during tests without trouble through distortion. The plate is made of .8 per cent, carbon steel. The clutch shaft has a stout Hardy flexible joint and conveys the drive to a four-speed gearbox three-point mounted in the chassis and with all its gears, including the reverse pinion, having teeth generated by grinding.

Ball bearings are used throughout, except for the floating spigot bush for the primary shaft. The splined shafts are ground on the splines and cores and hardened. The case itself is of cast steel, and the cover is inclined to one side, so permitting a reduction in the overall height, which, in the former gearbox, was increased by the casing for the selector mechanism. Owing to the length of the chassis and the forward position of the driver, a universally jointed shaft is pro

vided between the change-speed lever and the selector gear, the selector mechanism being of the ingenious type, involving a single rod only, which was employed in former models.

Behind the gearbox is an externally contracting foot brake with the familiar Bristol internal-cam operating gear.

The propeller shaft is 3 ins. diameter, 10 S.W.G. thick and constructed of 40-ton steel. The ends are pressed on hydraulically, turned steel rivets being driven through and cold-riveted. There are two Hardy joints on this shaft, one spider on each being extended to protect the joint.

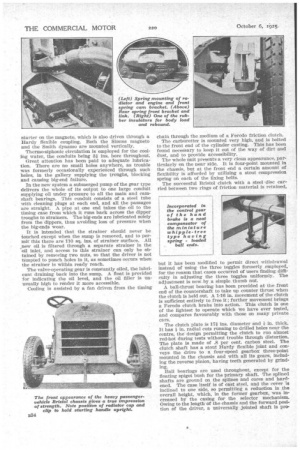

The final drive is through an underslung worm and six-pinion differential in a east-steel case, the engine and gearbox being both inclined to give a straight-line drive.

The rear springs are underslung, 1 in. fine-thread U bolts being employed. It has been found that the use of a Hardy joint insulates the engine tremors from the gearbox and thus greatly reduces noise.

The wheels are of the Dunlop steel-disc type equipped with 38-in. by 7-in. Dunlop tyres. The stub axles and pivot pins are so arranged as to provide centre-point steering, sufficient allowance being made to prevent wheel wobble. The stub axles are carried on plain Skefko roller bearings at the top and on taper roller bearings of the same make at the bottom. All the wheels have Skefloo double barrel-roller bearings at their outer ends, and single plain-roller bearings at their inner ends, but a huge Hoffmann thrust bearing Is provided for the worm drive. A. complicated double labyrinth is used on each wheel bearing to prevent loss of grease and entry of water. Tecalemit type Z greasers are fitted throughout.

The steering gear itself has a hardened steel quadrant and a hardened steel worm, whilst the joints are of the standard Bristol spring-loaded ball type, the transverse steering rod being of Vickers nickel-chrome steel.

The rear springs have internal-expanding shoes faced with Ferodo, the operating gear being of the special Bristol cam type with adjustable shoe ends. A miniature whipple tree compensator with a spring-loaded, ball-ended whipple is employed. Incidentally, a worm and wheel adjuster is provided for the foot brake lever.

The radiator is a Spiral Tube component with steel protecting tubes across it. It is supported between compression springs at each side.

The engine cowling is attached to the body, not to the chassis, for the purpose of insulating it from noise, and the radiator is shrouded so that the body and the radiator can move independently.

The makers are now testing out a new piston by which oil consumption has been wonderfully reduced.

The main dimensions of the Bristol heavy chassis are as follow :—Wheelbase, 16 ft. ; overall width at rear, 6 ft. 101 ins, with solid tyres, 7 ft. 41 ins, with pneumatic tyres ; the wheel track at the front is 6 ft. 41 ins. with solid tyres and 6 ft. 3i ins. with pneumatics.

Either of two final-drive gear ratios can be provided, these being 61 to 1 and 7 2-3 to 1. The gearbox ratios are :—Top, direct ; third, 1.6 to 1; second, 2.4 to 1; first, 4.5 to 1; reverse, 4.1 to 1. With the higher gear axle the corresponding ratios and road speeds are :— 6.5 to 1, 29 m.p.h.; 10.3 to 1, 18 m.p.h. ; 15.9 to 1, 12 m.p.h. ; 29.0 to 1, 6 m.p.h.; 26.4 to 1, 7 m.p.h. With the lower gear axle the ratios and speeds are :-7.7 to 1, 24 ; 12.2 to 1, 15 m.p.h. ; 18.7 to 1, 10 m.p.h.; 34.2 to 1, 5.5 m.p.h.; 31.4 to 1, 6 m.p.h. These speeds are with giant pneumatic tyres, 38 ins. by 7. ins., or solid tyres, 1,010 mm. by 140 mm., and with the engine governed to 1,600 r.p.m.

The Exhibits for Olympia.

The exhibits for the Commercial Motor Transport Exhibition will include this new chassis equipped with a 32-seater single-deck body—although actually it is designed for double-deckers ; a similar chassis, bare, and with a certain amount of Show finish ; and the new units mounted separately, including a gearbox in motion so that gear-changing can be effected. There will also be a 2-ton, forward-drive chassis as a 20-seater bus, a similar chassis, bare, and the 2-ton units shown separately.