Distributor Pump on Latest Chieftain

Page 68

Page 69

If you've noticed an error in this article please click here to report it so we can fix it.

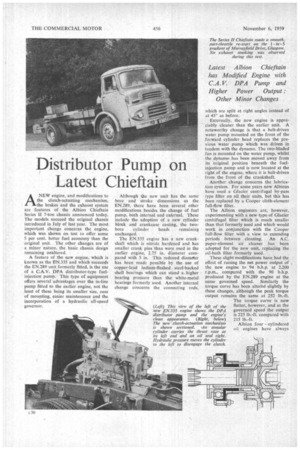

ANEW engine, and modifications to the clutch-actuating mechanism, the brakes and the exhaust system are features of the Albion • Chieftain Series II 7-ton chassis announced today. The models succeed the original chassis introduced in July of last year. The most important change concerns the engine, which was shown on test to offer some 5 per cent, better fuel economy than the original unit. The other changes are of a minor nature, the basic chassis design remaining unaltered.

Afeature of the new engine, which is known as the EN.335 and which succeeds the EN.289 unit formerly fitted, is the use of a C.A.V. DPA distributor-type fuelinjection. pump. This type of equipment offers several advantages over the in-line pump fitted to the earlier engine, not the least of these being its smaller size, ease of mounting, easier maintenance and the incorporation of a hydraulic all-speed governor.

Although the new unit has the same bore and stroke • dimensions as the EN.289,• there have been several other modifications besides the change of fuel pump, both internal and external. These include the adoption of a new cylinder block and crankcase casting, the two bore cylinder heads remaining unchanged.

The EN.335 engine has a new crankshaft which is. nitride hardened and has smaller crank pins than were used in the earlier engine, 2.75 in. diameter compared with 3 in. This reduced diameter has been made possible by the use of copper-lead indium-flashed steel-backed shell bearings which can stand a higher bearing pressure than the white-metal bearings formerly used. Another internal change concerns the connecting rods,

which are split at right angles instead of at 450 as before.

Externally, the new engine is appreciably cleaner than the earlier unit. A noteworthy change is that a belt-driven water pump mounted on the front of the forward cylinder head replaces the previous water pump which was driven in tandem with the dynamo. The two-bladed fan is mounted on the water pump, whilst the dynamo has been moved away from its original position beneath the fuelinjection pump and is now located at the right of the engine, where it is belt-driven from the front of the crankshaft.

Another change concerns the lubrication system. For some years now Albions have used a Glacier centrifugal by-pass type filter on all their units, but this has been replaced by a Cooper cloth-element full-flow filter.

• The Albion engineers are, however, experimenting with a new type of Glacier centrifugal filter which is much smaller than that formerly used and which would work in „conjunction with the Cooper full-flow filter with a view to extending periods between cleaning. An AC. paper-element air cleaner has been adopted for the new unit, replacing the oil-bath filter formerly used.

These slight modifications have, had the effect of raising the net power output Of the new engine to 94 b.h.p. at 2,200 r.p.m., compared with the 90 b.h.p. produced by the EN.289 engine at the same governed speed. Similarly the torque curve has been altered slightly by these changes, although the peak torque output remains the same at 252 lb.-ft. The torque curve is now flatter, however, and at the governed speed the output is 225 lb.-ft. compared with 215 lb-ft.

Albion four cylinidered oil engines have always been renowned for their lusty note, and the 1958 chassis was no exception in this respect, having a short transverse exhaust system with a diminutive tail pipe.

This wsthetic shortcoming is alleviated on the latest models, which have tail-pipe extensions to bring the exhaust outlet immediately ahead of the off-side . rear wheels. This extension both quietens the exhaust note and smooths the beat.

A novel method of clutch actuation has been adopted in the new engine. The EN.289 unit had a hydraulically operated clutch with an external slave cylinder which is worked through a lever and cross-shaft. This arrangement has been cleaned up by a patented Albion method, which employs an annular hydraulic cylinder which can slide to and fro along the cylindrical boss which surrounds the clutch shaft.

This cylinder carries the thrust race at its forward end whilst at the rear end there is an annular oil seal. The space behind this seal is in circuit with the clutch-actuating hydraulic circuit, thus all the moving parts of the clutch withdrawal mechanism are totally enclosed within the clutch bell housing. This system has been tested by the Albion engineers for many millions of cycles and has now 'reached the stage of being practically faultless.

Separate Reservoir With regard to the braking system, the Clayton Dewandre HS.I/950 Hydrovac vacuum servo used on the original Chieftain, in conjunction with a separate vacuum reservoir, has been replaced by an HSR.1/950 servo, which has -an integral reservoir. This new servo has been adopted mainly because of the difficulty of finding room for a separate reservoir on the short-wheelbase Chieftain chassis.

A minor modification affecting the braking system is that the mechanical stop-light switch formerly fitted is replaced by a hydraulic pressure unit for greater reliability.

The standard tyre equipment on the previous Chieftain chassis was 8.25-20-in. (12-ply), which allowed a gross vehicle weight of 10 tons 4 cwt. This weight rating has now been increased to 101 tons by fitting as standard 8.25-20-in. (14-ply) tyres.

In all other respects the Chieftain chassis as originally introduced in July, 1958, are unchanged. This applies to the standard all-steel cab also, except that a three-bolt fixing has been adopted for the mirror mountings on the cab doors, this arrangement being less prone to vibration than the two-bolt arrangement formerly used:

I was granted the exclusive facility of obtaining performance figures on the first of these new Chieftains (writes John F. Moon). The vehicle offered to me had basically the same specification as the example tested earlier (The Commercial Motor, July 4, 1958) and had been loaded up to the same gross weight10 tons 17 cwt. The rear-axle ratio also was the same-6.25 to 1—and, as in 1958, the overdrive-top gearbox was fitted As a test for engine power, the Series II -Chieftain was taken to Murrayfield Drive, Westerton, blasgow, which has a slope of 1 in 5. On this gradient an easy partthrottle restart was made in bottom gear although an attempt to move away in second gear was unsuccessful.

From Glasgow, the 7-tonner was taken out to Buchlyvie for a fuel-consumption run, thisbeing the same course over which 19.2 m.p.g. was obtained last year at an average speed of 30 m.p.h.

On this occasion, the 10-mile course was -completed at an average speed of 34.9 m.p.h. and the consumption rate was 20 m.p.g. These results gave a gross ton-m.p.g. figure of 217 and a time-loadmileage factor of 7,600, compared with the figures of 209 and 6,270 obtained last year. This is a worthwhile improvement.

Other fuel-consumption tests carried out over an undulating course gave average figures of 18.5 m.p.g. at an average spied of 34.4 m.p.h.—truly out standing economy for a vehicle of this weight.

Acceleration figures taken with the new Chieftain showed its performance through the gears between a standstill and 40 m.p.h. to be almost identical, whilst it took 4 sec.longer to reach 30 m.p.h. from 10 m.p.h. in direct drive.

Hill climbing was shown to be improved, however, . an ascent of the 1.3-mile climb of Gleniffer Braes, Paisley, being completed in 5 min. 55 sec. which is 1 mm. 5 sec. faster than the ascent made last year. On this occasion, the lowest gear employed was third, whilst in 1958 second gear was used for 11 sec.

A higher final engine-coolant temperature was recorded, the thermometer reading being 190° F., but this would be because a different thermostat is used in the new engine and this opens at 185° F. compared with 165° F. This higher opening temperature increases both engine and cab-heater efficiency.