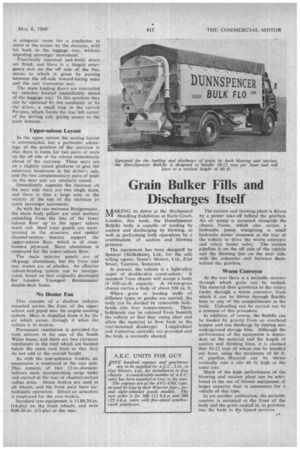

Grain Bulker Fills and Discharges Itself

Page 99

If you've noticed an error in this article please click here to report it so we can fix it.

M1AKING its debut at the Mechanical ' Handling Exhibition at Earls Court, London, this week, the DunnSpencer Bulkflo body is capable of loading by suction and discharging by blowing, as well as performing both operations by. a combination of suction and blowing pressure.

The equipment has been designed by Spencer (Melksham), Ltd., for the sole selling agents, Dunn's Motors, Ltd., East Street, Taunton, Somerset.

In essence. the vehicle is a light-alloy tipper of double-skin construction. A standard 7-ton chassis will accept a body of 450-cu.-ft. capacity. .A 14-ton-gross chassis carries a body of about 500 cu. ft.

Where grain or feeding stuffs of different types or grades are carried, the body can be divided by removable bulkheads into four compartments. These bulkheads can be released from beneath the vehicle so that they swing clear and allow the material to flow back to the rear-mounted discharger. Longitudinal and transverse catwalks are provided, and the body is normally sheeted. The suction and blowing plant is driven by a power take-off behind the gearbox. An air pump is mounted alongside the chassis frame, which also carries a hydraulic pump energizing a small hydraulic motor mounted at the rear of the vehicle to drive the worm conveyor and rotary feeder valve. The suction pipeline is on the off side of the vehicle and the blowing line on the near •side, with the exhauster unit between them. behind the gearbox.

Worm Conveyor

At the rear there is a portable receiver through which grain can be sucked. The material then gravitates to the rotary feeder through a worm conveyor, from which it can be blown through flexible hose to any of the compartments in the body. Unloading can be carried out by a reversal of this procedure.

In addition-, of course, the Bulkflo can be loaded by gravity from an overhead hopper and can discharge by tipping into underground storage bins. Although the performance of the eauipment is dependent on the material and the length of suction and blowing lines, it is claimed that 10-12 tons of wheat can be handled per hour, using the maximum of 60 ft. of pipeline. Material can be blown vertically into a silo 40 ft. high at the same rate.

Much of the high performance of the blowing and suction plant can be attributed to the use of blower equipment of larger capacity than is customary for a vehicle of this type.

In yet another application, the portable receiver is mounted at the front of the body and the grain sucked in, to gravitate into the body in the tipped position. •