TIP FOR THE TOP

Page 38

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

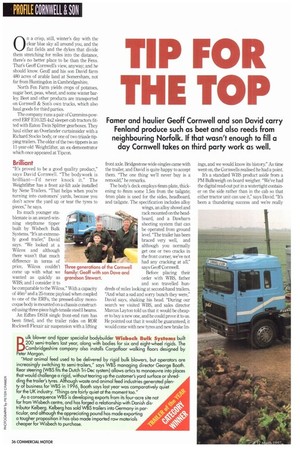

Famer and haulier Geoff Cornwell and son David carry Fenland produce such as beet and also reeds from neighbouring Norfolk. If that wasn't enough to fill a day Cornwell takes on third party work as well.

0 n a crisp, still, winter's day with the clear blue sky all around you, and the flat fields and the dykes that divide them stretching for miles into the distance, there's no better place to be than the Fens. That's Geoff Cornwell's view, anyway; and he should know. Geoff and his son David farm 480 acres of arable land at Somersham, not far from Huntingdon in Cambridgeshire.

North Fen Farm yields crops of potatoes, sugar beet, peas, wheat, and some winter barley. Beet and other products are transported on Cornwell & Son's own trucks, which also haul goods for third parties.

The company runs a pair of Cummins-powered ERF E10.325 4x2 sleeper-cab tractors fitted with Eaton Twin Splitter gearboxes. They haul either an Overlander curtainsider with a Richard Stocks body, or one of two triaxle tipping trailers. The older of the two tippers is an 11-year-old Weightlifter, an ex-demonstrator which once appeared at Tipcon.

Brilliant

"It's proved to be a good quality product," says David Cornwell. "The bodywork is brilliant—I'd never knock it." The Weightlifter has a front air-lift axle installed by Nene Trailers. "That helps when you're turning into customers' yards, because you don't screw the yard up or tear the tyres to pieces," he says.

Its much younger .stablemate is an award-winning stepframe tipper built by Wisbech Bulk Systems. "It's an extremely good trailer," David says. "We looked at a Wilcox and although there wasn't that much difference in terms of price, Wilcox couldn't come up with what we wanted as quickly as WBS; and I consider it to be comparable to the Wilcox." With a capacity of 46m3 and a 25-tonne payload when coupled to one of the ERFs, the pressed-alloy monocoque body is mounted on a chassis amstructed using three-piece high-tensile steell-beams.

An Edbro DS18 single front-end ram has been fitted, and the trailer rides on ROR Rockwell Flexair air suspension with a lifting Three generations family: Geoff with grandson Stewart front axle. Bridgestone wide-singles came with the trailer, and David is quite happy to accept them. "The one thing we'll never buy is a remould," he remarks.

The body's deck employs 6mm plate, thickening to 8mm some 1.5m from the tailgate; 4mm plate is used for the sides, headboard, and tailgate. The specification includes alloy wings, an alloy shovel and rack mounted on the headboard, and a Dawbarn sheeting system that can be operated from ground level. "The trailer has been braced very well, and although you normally get one or two cracks in the front corner, we've not had any cracking at all," says Geoff Cornwell.

Before placing their order with WBS, father and son travelled hundreds of miles looking at second-hand trailers. "And what a sad and sorry bunch they were," David says, shaking his head. "During our search we visited WBS, and sales director Marcus Layton told us that it would be cheaper to buy a new one, and he could prove it to us. He pointed out that it would be guaranteed, it would come with new tyres and new brake lin of the Cornwell son Dave and ings, and we would know its history." As time went on, the Cornwells realised he had a point.

It's a standard WBS product aside from a PM Bulkweigh on-board weigher. "We've had the digital read-out put in a watertight container on the side rather than in the cab so that either tractor unit can use it," says David. "It's been a thundering success and we're really pleased with it. Fitting one to the Weightlifter is very much in our minds."

The Cornwells have been "involved in transport for well over 40 years," David explains. "Up until 10 years ago we ran a dozen vehicles, and had 15,240m2 of warehousing." But the business needed more investment, and Geoff Cornwell, now retired, had to decide whether to put money into lorries or farming. He chose trucks, the warehousing was disposed of, and the fleet shrunk to three: "By the early 'nineties we had one lorry, and things were so bad in haulage that we decided to give the driver his notice," David recalls. "And he'd been with us almost 18 years."

Harvest

The driver couldn't find another job, so the Cornwells re-employed him and decided to put the truck on to container haulage until harvest time. Then one of the firms which had taken on some of their warehousing offered them work, and for the past three years they've been running two vehicles.

"The ERFs we now have were three years old when we bought them from an ad in CM," says David. "They've been quite good motors, although one had a camshaft break which meant we had to replace the engine." The trucks tackle groupage to the North of England and running beet into the local British Sugar factory. "The beet season runs from the end of September to the end of February," says David. "We also bring in 20 or 30 loads of Norfolk reed every year on a rented tandem-axle flatbed. The reed is used by thatchers, and it's a different sort of a job because you go out into the Norfolk Broads and a gang of men load the trailer by hand. There's no weight involved—five or six tonnes of reeds looks like a giant mobile haystack going down the road.

"We do a small amount of work for London Brick too," he adds. "Not much, because the way the rates are structured doesn't encourage us to go in there too often."

The Cornwells do all their own servicing but major repairs are tackled by Peterborough ERF distributor Sellers & Batty, or Welch's of Cambridge. David agrees that the trucks are probably over-maintained, but make no apologies for it: "Dad always says that grease is cheaper than metal, and he's right," he says.

If you really want to upset David Cornwell, start talking about farmers using agricultural tractors and trailers to compete with legitimate haulage operations like his. "Some of these guys are working 18 hours a day, and there's nothing to stop them," he fumes. "It shouldn't be allowed, and it's about time the authorities woke up to it."

El by Steve Banner