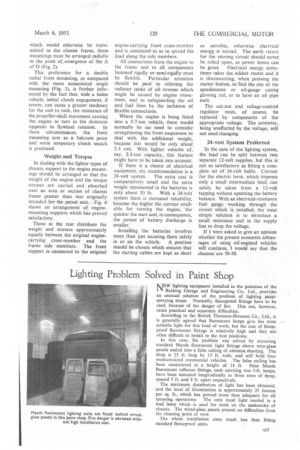

Lighting Problem Solved in Paint Shop

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

NEW lighting equipment installed in the premises of the Barking Garage and Engineering Co., Ltd., provides an unusual solution of the problem of lighting paintspraying shops. Normally, flameproof fittings have to be used, because of the danger of fire. This can, however, cause practical and economic difficulties.

According to the British Thomson-Houston Co., Ltd., it is generally agreed that fluorescent lamps give the most suitable light for this kind of work, but the cost of flameproof fluorescent fittings is relatively_ high and they are often difficult to install in the best positions. In this case, the problem was solved by mounting standard Mazda fluorescent light fittings above wire-glass panels sealed into a false ceiling of asbestos sheeting. The shop is 25 ft. long by 15 ft. wide, and will hold_ four medium-sized commercial vehicles. The false ceiling has been constructed at a height of 14 ft. Nine Mazda fluorescent reflector fittings, each carrying two 5-ft. lamps, have been mounted longitudinally in three rows of three, spaced 5 ft. and 8 ft. apart respectively.

The maximum distribution of light has been obtained, and the level of illumination is approximately 25 lumens per sq. ft., which has proved more than adequate for all spraying operations. The only local light needed is a lead lamp which is used for work on the undersides of chassis. The wired-glass panels present no difficulties from the cleaning point of view.

The whole installation costs much less than fitting standard flameproof units.