A TRAILER TANK WAGON FOR HIGH SPEEDS.

Page 10

If you've noticed an error in this article please click here to report it so we can fix it.

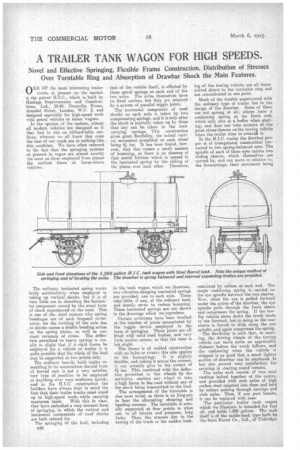

Novel and Effective Springing, Flexible Frame Construction, Distribution of Stresses Over Turntable Ring and Absorption of Drawbar Shock the Main Features.

ONE OF the most interesting trailer trucks at present on the market is the patent H.I.C., which is built by Haulage Improvements and Constructions, Ltd., 39-40, Granville House, Arundel Street, London, W.C. 2, and designed especially for high-speed -work with petrol vehicles or steam wagons.

In the opinion of the makers, almost all modern vehicles 'are designed as if they had to run on billiard-table surfaces, whereas we all know that even the best of our roads are in nothing like, this condition. We have often referred to the fact that the springing systems at present in vogue are almost exactly the same as those employed from almost the earliest times on horse-drawn vehicles.% The ordinary laminated spring works fairly satisfactorily when employed in taking up vertical shocks, but it is of very little Use in absorbing the horizontal component caused by the.usual form of shock experienced on the road. This is one of the chief reasons why spring breakages are of such frequent occurrence, for the twisting of the axle due tO shocks causes a double bending action on the spring plates, as well as constant reversals of stress. The deflection permitted on heavy springs is usually so slight that. if a rigid frame be employed or a vehicle or trailer it is quite possible that the whole of the load may be supported at two points only.

The ordinary heavily built trailer resembling in its construction theeald form of horsed cart is not a very satisfactory type of „machine to be employed at anything over very moderate speeds, and in the H.I.C. construction the builders have always kept in mind the fact, that, their trailer trucks must stand up to high-speed work., while carrying maximum loads. With this in view, they have embodied a very unusual form of springing, in which the vertical and horizontal components of road shocks are both catered for.

The springing of the load, including 82G

that of the vehicle itself, is effected by three spiral springs at. each end of the two axles. The axles themselves have no fixed centres, but. they are retained by a system of parallel toggle joints.

The horizontal component of road shocks on each axle is taken by two compensating springs, and it is only after the shock is partially taken up by these that any can be taken to the loadcarrying springs. This construction gives great flexibility, the actual vertical movement permitted on each wheel being 41 ins. It has been found, however, that this causes a small amount. of bouncing, as there is an absence of that useful friction which is caused in the laminated spring by the sliding of the plates over each other. Therefore, in the tank wagon which we illustrate, two vibration-damping laminated springs are provided, one to each axle. These take little, if any, of the ordinary load, and merely serve to reduce bouncing. These laminated springs are not shown in the drawings which we,reproduce. Certain criticisms have been levelled at the number of joints necessitated by the toggle device employed in the form of springing. These joints are all fitted with mild steel bushes, and very little motion occurs, so that the wear is but slight.

The frame is of welded construction with no bolts or rivets; this also applies to the forecarria.ge. It, is slightly flexible, and, taking it across the corners. it can actually give to the extent of 4; ins. This combined with the deflection permitted to the wheels by the springing, enables any wheel to take a-high hump in the road without any of the shock being transmitted to the load.

The arrangement of the turntable is also most novel, as there is no king-pin to bear the alternating shearing and bending stresses. The turntable i.s actually supported at four pointsin what are, to all intents and purposes, long forks. Thus, the stresses due to the towing of the truck or the sudden brak

ing of the towing vehicle, are all transmitted direct to the turntable ring and not concentrated at one point.

Much of the trouble experienced with the ordinary type of trailer lies in the design of the drawbar. Some of these are not sprung at all; others have a cushioning spring at the front end, which only acts as a buffer when starting; and does not take accotait of the great stress thrown on the towing vehicle when the trailer tries to overrna it.

In the H.I.C. trailer the drawbar proper is of triangulated construction connected to two spring-balanced eyes. The spindle of each of these eyes carries two sliding sleeves, which themselves are carried by, and can move in relation to, the forecarriage, their movement being

restricted by collars at each end. The single cushioning spring is carried oil the eye spindle between the two sleeves. Now, when the eye is pulled forward under the action of the drawbar, the eye spindle pulls through the front sleeve and compresses the spring. If the towing vehicle slows down the truck tends to run forward, but in doing so the rear sleeve is forced to slide along the eye spindle, and again compresses the spring. The flexibility is such that, in starting, the driving wheels of the towing vehicle can move quite an appreciable distance before the truck follows, and the cushioning when the vehicle is stopped is so good that a much lighter section of-drawbar can be employed. It has also proved very satisfactory for assisting in steering round corners.

The axles each consist, of two steel castings bolted together at the centre, and provided with stub axles of high carbon steel spigoted into them and held by cotters passing through castings and stub axles. Thus, if any part breaks, it can he replaced with ease. The particular trailer tank wagon which we illustrate is intended for fuel oil, and holds 1.200 gallons. The tank itself is of the saddle-hack type built by the Steel Barrel Co., Ltd., of Uxbridge.