Practical Aspects of

Page 38

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

ENGINE BALANCE

TECHNICALITIES of balancing, as applied to reciprocating engines, hae represented an established text-book subject, based on known mathematical analyses„ since the early days of the internal-combustion power unit. There have been no startling new developments to upset accepted data, but those who do not keep in daily touch with related problems are often prone to confused thinking when practical applications are considered. Some text-book authors over-simplify the factors involved; others treat the subject mathematically throughout, and the essentials cannot be grasped without exhaustive refresher work on the part of the reader. This article is an attempt to fill the gap between the two extremes.

A fully balanced engine is one which, theoretically, does not vibrate on its mountings except under the influence of torque reactions. The crankshaft of a multi-cylindered engine may be " balanced" or "unbalanced " without affecting the balance of the engine as a unit, and it is necessary to differentiate between part balancing and unit balancing. Whilst weights are often added to the crank webs of a single-cylindered engine to improve balance, the main object of using these weights in both single and multi-cylindered engines is to reduce the maximum inertia loading on the main bearings and to regulate the loading diagram to meet both stress and lubrication requirements. For this purpose, consideration is sometimes given to gas pressures which do not influence the balance of the engine as a whole because they produce a reaction force on the head equal to the force on the piston.

Vibrations which are in practice caused by power impulses, are the result of internal deflection, or distortion of the components, the most serious being torsional vibrations which result from crankshaft twisting and untwisting. Stress vibrations cannot be balanced. Their amplitude is reduced to a minimum by stiffening the parts, which is desirable both to reduce vibration and to avoid premature. fatigue fractures. In a highspeed engine, the torsional vibrations of the crankshaft may reach a frequency which corresponds to the natural frequency of the shaft, and resonance occurs_ Amplitudes then, theoretically, become infinite unless a damper be fitted to control the deflections. Whilst damping, or vibration absorption, is related to balancing, its treatment as a subject must be considered separately.

Balancing a multi-cylindered engine is complicated by the angularity of the connecting rod. If this part were of infinite length, the piston would have a simple harmonic motion; its maximum speed would occur at 90 degrees of crankshaft rotation after t.d.c., and the second half of the stroke would be similar, in a reverse,' sense, to the top half. In terms of inertia loading, the force would be applied and reversed at the same rate, and the resultant vibration (of an unbalancd engine) would be of simple form with a frequency equal to that of the crankshaft speed.

Because of connecting-rod angularity, maximum piston speed is reached when the connecting rod and crank are at right angles and the crank has moved through less than 90 degrees from t.d.c. During the stroke of the piston a force is therefore applied through

bout 76 degrees and is reversed through the remaining ngIe of 104 degrees. Whilst t.d.c. and b.d.c. are both ko lilts of maximum acceleration in the respective parts I the oscillating cycle, it follows that the accelerating orce at b.d.c. is less than the force at t.d.c.

The effect of this is extremely complex. Forces are enerated, supplementary to the primary force, which re represented by an infinite series (the Fourier series') f decreasing magnitude but of increasing frequency. Iarmonics are produced akin to the percussion bar'Ionics of a violin Or piano string which determine the tone' of the note. Fortunately, all unbalanced forces fter the secondary are of such small magnitude that Icy need not be taken into account. The secondary as a frequency double that of the primary and of bout a quarter the magnitude.

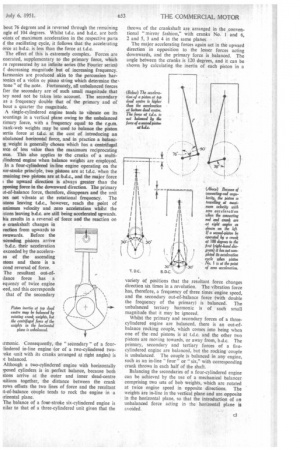

A single-cylindered engine tends to vibrate on its iountings in a vertical plane owing to the unbalanced rimary force, with a frequency equal to the rpm. 'Tank-web weights may be used to balance the piston iertia force at t.d.c at the cost of introducing an nbalanced horizontal force, and in practice a balaticig weight is generally chosen which has a centrifugal 'me of less value than the maximum reciprocating nee. This also applies to the cranks of a multiylindered engine when balance weights are employed. in a four-cylindered in-line engine operating on the mr-stroke principle, two pistons are at t.d.c. when the .tmaining two pistons are at b.d.c., and the major force the upward direction is always greater than the pposing force in the downward direction. The primary ut-of-balance force, therefore, disappears and the unit oes not vibrate at the rotational frequency. The stons leaving t.d.c., however, reach the point of aximum velocity and zero acceleration whilst the [stons leaving b.d.-c. are still being accelerated upwards. his results in a reversal of force and the reaction on e crankshaft changes in motion from upwards to Dwrovards. Before the ,seending pistons arrive b.d.c. their acceleration exceeded by the acceleraon of the ascending stons and there is a cond reversal of force. The resultant out-ofdance force has a equency of twice engine Iced, and this corresponds that of the secondary irmonic. Consequently, the " seCondary " of a fourlindered in-line engine (or of a two-cylindered two-oke unit with its cranks arranged at right angles) is )t balanced.

Although a two-cylindered engine with horizontally ,posed cylinders is in perfect balance, because both stons arrive at the outer and inner dead-centre isitions together, the distance between the crank rows offsets the two lines of force and the resultant it-of-balance couple tends to rock the engine in a Irizontal plane.

The balance of a four-stroke six-cylindered engine is nilar to that of a three-cylindered unit given that the throws of the crankshaft are arranged in the conventional "mirror fashion," with cranks No. 1 and 6, 2 and 5, 3 and 4 in the same planes.

The major accelerating forces again act in the upward direction in opposition to the lesser forces acting downwards, and the primary force is balanced. The angle between the cranks is 120 degrees, and it can be shown by calculating the inertia of each piston in a variety of positions that the resultant force changes direction six times in a revolution. The vibration force has, therefore, a frequency of three times engine speed, and the secondary out-of-balance force (with double the frequency of the primary) is balanced. The unbalanced tertiary harmonic is of such small magnitude that it may be ignored.

Whilst the primary and secondary forces of a threecylindered engine are balanced, there is an out-ofbalance rocking couple, which comes into being when one of the end pistons is at t.d.c. and the other two pistons are moving towards, or away from, b.d.c. The primary, secondary and tertiary forces of a fivecylindered engine are balanced, but the rocking couple is unbalanced. The couple is balanced in any engine, such as an in-line " four " or "six," with corresponding crank throws in each half of the shaft.

Balancing the secondaries of a four-cylinderecl engine can be achieved by the use of a mechanical balancer comprising two sets of bob weights, which are rotated at twice engine speed in opposite directions. The weights are in-line in the vertical plane and are opposite in the horizontal plane, so that the introduction of an unbalanced force acting in the horizontal plane is avoided.