THE MAUDSLAY BRAKE.

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

A Résumé of Recently Published Patent Specifications.

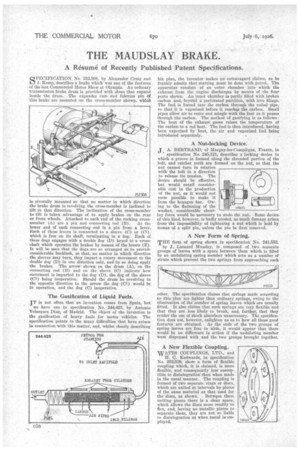

PECIFICATION No. 252,508, by Alexander Craig and :1". Kemp, describes a brake which was one of the features of the last Commercial Motor Show at Olympia. An ordinary

• transmission brake drum is provided with shoes that expand inside the drum. The expander cam and fulcrum pin 01 this brake are mounted on the cross-member showp, wh'ich is pivotally mounted so that no matter in which direction the brake drum is revolving the cross-member is inclined to tilt in that direction. The inclination of the cross-member to tilt is taken advantage of to apply brakes on the rear or front wheels. Attached to each end of the rocking crossmember (A) are a pin and connecting rod (B). At the lower end of each connecting rod is a pin from a lever. Each of these levers is connected to a sleeve (C) or (CI), which is free on its shaft, terminating in a dog. Each of these dogs engages with ,a double dog (D) keyed to a crossshaft which operates the brakes by means of the levers (E). It will be seen that the dogs are so arranged a-s to provide considerable backlash, so that, no matter in which direction the sleeves may turn, they impart a rotary movement to the double kg (D) in one direction only, and by so doing apply the brakes. The arrow shown on the drum (A), on the connecting rod (B) and on the sleeve (C) indicate how movement is imparted to the dog (D), the dog of the sleeve (C1) being inoperative. Should the drum be revolving in the opposite direetion to the arrow the dog (01) would be in operation, and the dog (C) inoperative.

The Gasification of Liquid Fuels.

IT is not often that an invention comes from Spain, but

we have one in specification No. 244,423, by Antonio Velazquez Diaz, of Madrid. The object of the invention is the gasification of heavy fuels for motor vehicles. The specification 'points to the many difficulties that have arisen in connection with this matter, and, whilst clearly describing his plan, the inventor makes no extravagant claims, as he frankly admits that starting must be done with petrol. The apparatus . consists of an outer chamber into which the exhaust from the engine discharges by means of the four. ports shown. An inner chamber is partly filled with broken carbon and, beyond a perforated partition, with iron filings. The fuel is forced into the carbon through the coiled pipe, so .that it is vaporized before it reaches the carbon. Small pipes allow air to enter and mingle with the fuel as it passes through the carbon. The method of gasifying is as follows : The heat of the exhaust gases raises the temperature of the carbon to a red heat. The fuel is then introduced, having been vaporized by heat, the air and vaporized fuel being introduced separately.

A Nut-locking Device: J . A. BERTRAND, of Margrey-les-Compi4ne, France, in specification No. 245,121, describes a locking device in which a groove is formed along the threaded portion of the bolt, and ratchet teeth are formed on the nut, so that the nut cannot turn in relation with the bolt in a direction to release its tension. The device should be effective, but would entail considerable cost in the production of the nut, as it would not seem possible to make it from the hexagon bar. Owing to the flattening of the washer, considerable shearing force would be necessary to undo the nut. Some device of this kind, however, is badly needed, as much damage arises from the imposiibility of tightening a nut which is held by moans of a split pin, unless the pin be first removed.

1:11

A New Form of Spring.

THE form of spring shown in specification No. 241,553,

by J. Leonard Munday, is composed of two separate groups of leaves with a space between them which is filled by an .undulating spring member which acts as a number of struts which prevent the two springs from approaching each

other. The specification claims that springs made according to this plan are lighter than ordinarysprings, owing to the elimination of the number of spring leaves which are usually fitted. It also claims that such springs are very flexible and that they are less likely to break, and, further, that they render the use of shock absorbers unnecessary. The'spetification does not, however, enlighten us as td how all these good• features are obtained. As the ends of the two groups of spring leaves are free to slide, it would appear that there would be no difference in action if the undulating member were dispensed with and the two groups brought together.