The Sentinel

Page 38

Page 39

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

Under Stearn Again

BY L. J. COTTON

MY test of the Sentinel sixwheeler was my first encounter with a steam wagon, and it convinced me that the steam-engine power characteristics, affording high torque at low revolutions, are excellent in road vehicles, for they give rapid and smooth acceleration from rest to maximum speed. The manufacturer gave " The Commercial Motor" the first opportunity of making a comprehensive road test of a left-handdrive machine weighing 22 tons gross, one of the first of the shaft-driven steamers which are to be operated in the Argentine.

Suspended horizontally in the frame behind the cab, like the present Sentinel oil engine, the four-, cylindered single-acting steam engine has the cylinder blocks and heads arranged towards the right of the chassis. Pistons, connecting-rods and crankshafts of internal-combustion pattern are employed, but because every revolution of the crankshaft gives four power strokes, each pair of crank journals is set at an angle of 90 degrees. Weight has been greatly reduced by using light alloys in the construction of the crankcase and sump.

Developing a maximum of 124 b.h.p., the engine •is equipped withpoppet valves in a T-head formation, and the camshaftis arranged for . three cut-off positions and reverse.

B4 The foot control to the steam valve takes the form of an accelerator pedal, and the camshaft is turned to the cut-off position by a lever close to the driver.

Pressure lubrication is provided for the camshaft bearing and, through the connecting-rods, for the gudgeon pins. A weir-type separator attached to the side of the sump ensures that any water reaching the base is automatically drained from the lubricant.

A slow-running double-acting feed pump is incorporated in the engine, and supplies, through a valve controlled by the driver, a flow of water to the boiler. The boiler is of Sentinel vertical water-tube pattern mounted between the frame side members and placed vertically at the back of the cab, It operates at a working pressure of 255 lb. per sq. in. and incorporates a double superheater.

Rectangular water tanks are arranged behind the seats on each side of the boiler, and two bunkers, carrying a total of 61cwt. of coal, are fitted above the tanks. These bunkers :tre filled through hatches in the cab roof, and apertures are provided at their bases for hand firing of the boiler. Coal is fed into the top of the boiler, and rocking fire bars, operated by a lever in the cab, are fitted to assist combustion of lowgrade fuel, such as will be used in the Argentine.

A two-speed sliding spur gear is incorporated in an extension to the crankcase, the output shaft being co-axial with the crankshaft. As gear changes are normally made when the vehicle is stationary, there is no clutch or flywheel, but a large oscillation damper is fitted to the output shaft.

A short Hardy Spicer coupling shaft conveys the drive to the double.. drive bogie, which has three-quarterfloating axle shafts. The final drive is taken through a double-reduction gear comprising a spiral bevel operating a layshaft which, in turn, drives a double-helical crown wheel. Torque and braking reactions are taken by ball-ended radius rods.

The chassis is a conventional channel-section parallel • frame with tubular and pressed-steel cross-members bolted in position, and the bogie is attached by long brackets braced by a tube between the trunnions of the underslung reverse camber springs. These springs, one .on each side of the chassis, have trunnion sWivel eyes to relieve the leaves of any distortion during articulation.

Girling two-leadingshoe brakes are fitted on all wheels, and are operated through a Lockheed hydraulic continuous flow system with an enginedriven pump and a reservoir.

Twin tyres are fitted to the bogie, the standard equipment for all wheels being 42 ins. by 9 ins. The spare wheel is mounted behind the cab and has the Sentinel self-hoisting arrangement for lifting or lowering the carrier.

Fuel for the test was bagged and weighed overnight, the water tanks filled and the grate cleaned, in readiness for an early start on the consumption trial. To enable low-grade Fuel to be used. the fire bars were spaced at intervals of 1 in.. and the surface area of the boiler had been increased, so that 1 did. not expect consumption to be low. Normally, when Welsh steam coal is burned, the firebars are spaced in apart.

Because • the test was conducted with Welsh fuel, a large proportion of partially burned coal was discharged into the ashpan, and because of the rear hinging of the pan', the combination of forced draught' and widely spaced bars caused fuel to be used at an abnormal rate. To help to control the fire, it was started with coke to form clinker over the bars.

A bag of coke weighing 2 cwt. 7 lb. was used to raise steam, and the first pressure was shown on the gauge within 19 minutes of lighting up. The temperature of the feed water in the supply tanks was taken before starting the fire, and the reading of 50 degrees F. was 8 degrees above ambient. Preparations for the run were started at 7.20 a.m. By 8.03 a.m. 125 lb. per sq. in. of steam had been raised, and we drove on to the weighbridge in readiness for the road.

The fire was stoked with coal before leaving the works, and when entering Shrewsbury town, two miles away, the steam pressure was up to 225 lb. per sq. in., a practical working point. It required no mean driv a6 in skill to make a right-angle turn under a low, narrow, semi-circular bridge in the town, with a vehicle 8 ft. wide and 9 ft. 11 ins. high.

After we were clear of the town the Sentinel was speeded up, and although the course along the A5 road was undulating, the speed rarely fell below 25 m.p.h. Traffic on the narrow, tortuous route through Whittington caused a stop, but apart from this the run from the outskirts of Shrewsbury to Llangollen was unhindered.

The. England-Wales border was crossed at the foot of Chirk Hill, where the length and severity of the gradient required a halt to change gear. This was the first occasion which demanded the employment of the low ratio. The Tapley gradient meter was showing 1 in 14.

The steam-engine characteristics of high power at low speeds enabled the vehicle to move smoothly and steadily away from rest on this gradient. The camshaft lever was moved to mid cut-off position within 30 yds of this halt, and the steamer climbed at a steady 8 m.p.h., into Chirk.

The driver and stoker worked well as a team, and the boiler pressure was maintained within working limits without blowing the safety valve. This was some achievement, having regard to the air blast formed by the scoop of the ashpan and the wide spacing of the firebars. Our maximum speed along the Vale of Llangollen was in the region of 35 m.p.h., and 8 kilometres (five miles) were covered in 94 minutes. The distance was checked by milestones. and the speedometer was found to be accurate.

After turning at Llangollena halt was made at a stream across the golf course to replenish the water tanks, a distance of 32 miles having been covered on 140 gallons of water. Up to this point the reserve supply had remainded untouched, but this was a convenient point for replenishing. It took six minutes to refill the tanks, and the trial was resumed without -further delay.

I timed the vehicle over the same stretch of road as on the outward journey, and on the second occasion it took 134 minutes to cover five miles. More power was required on some of the return gradients, and the mid cut-off position of the camshaft lever was employed more extensively.

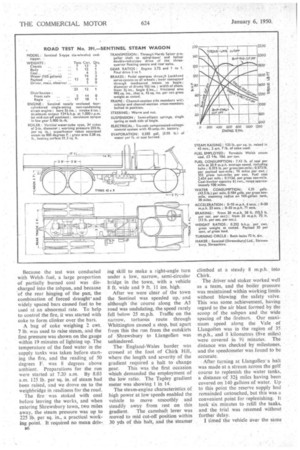

The 624-mile course was completed in 3 hrs. 2 mins., including the stop for water, which corresponds to an average speed of 20.6 m.p.h. A total of 270 gallons of water and 4 cwt. 13 lb. of coal were used, equalling 4.35 gallons of water and 7.43 lb. of coal per mile. The fuel consumption would have been lower had the firebox been designed for the grade of fuel employed and the route less hilly. As Welsh steam coal costs 13 14s. 10d. a ton, supplied at Shrewsbury, the cost of fuel per mile works out at 2.65d.

Coal and water supplies were replenished for the short performance and hill-climbing tests. The stoker built up the fire as we approached Harley Hill, known locally as Wenlock Bank, which is a mile climb of 1 in 13 average gradient.

Good Hill-climbing

Low gear was engaged during the first quarter of a mile and then we steamed steadily up with the camshaft in late cut-off position. Much to the astonishment of its driver, a well-laden 5-tanner was overtaken on the hill. The Sentinel toiled up the hill and appeared to get second wind when climbing over the 1-in-64 section at 4 m.p.h. There was a slight reserve of power on this gradient.

Having negotiated the hill without much difficulty, we refilled the water tanks in Much Wenlock, and started the return journey. Low gear was engaged when descending Harley Hill and the pace was kept under control by occasional use of the foot brake.

Acceleration and braking tests were made on the outward and return journeys, and average results obtained from the readings. The Lockheed braking system with twoleading-shoe application proved fully effective with a 234-ton load, the stopping distances being n ft. from 20 m.p.h. and 75 ft. from 30 m.p.h.

Because it is not customary or easy to change gear on the move when driving a steamer, the acceleration tests were made in high ratio, this enabling a speed of 30 m.p.h. to be reached. Six secs. were needed to reach 10 m.p.h. from rest, 23 sees. to 20 m.p.h., and 71 secs. to 30 m.p.h. On level ground the maximum speed was slightly over 30 m.p.h., but, of course, this is easily surpassed on any slight decline.

Apart from the size of the vehicle and its left-hand control, the steamer was not difficult to drive. Naturally, to steer a large left-hand-drive machine along country roads called for care, but I made rather more stops than necessary just for the pleasure of observing the smooth getaway. To keep a steady flow of water to the boiler was one of my problems, although the mirror on the dash panel reflecting the boiler side glass was helpful, and an accom

plished steamer driver would make a routine check every few minutes.

Towards the end of the day, after much hill-climbing, the cab -temperature crept up to 87 degrees F., but with fully opening windows at the front and sides of the cab, the temperature can be controlled within reasonable limits. As it was a cold afternoon the " fug " raised by having all windows closed was not entirely unwelcome.