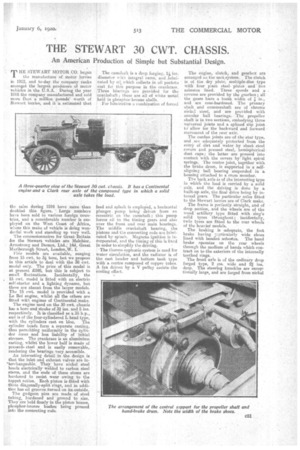

THE STEWART 30 CWT. CHASSIS.

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

An American Production of Simple but Substantial Design.

THE STEWART MOTOR CO: began the manufacture of motor lorries in 1912, and to-day the company ranks amongst the largest producers of motor vehicles in the U.S.A. During the year 1918 the company manufactured and sold more Chan a million pounds' worth of Stewart lorries, and it LS estimated that

the sales during 1919 have mere than doubled this figure. ' Large numbers have been sold in various foreign countries, and a considerable number is employed on the West Coast of Africa, where this make of vehicle is doing wonderful work and standing up very well..

The concessionnaires for Great Britain for the Stewart vehicles are Melchior, Armstrong and Dessau Ltd.' 14d, Great Marlborough Street, LO'ndon,W. 1.

Five models are available, ranging from 15 cwt. to 3i tons, but we propose in this article to deal with the 30 cwt. model only. The price of this model is at present £595, but this is subject to small fluctuations. Incidentally, the 15 cwt.. model is fitted with an electric self-starter and a lighting dynamo, but these are absent from the larger models. The 15 cwt. model is provided with a Le Roi engine, whilst all the others are fitted with engines of Continental make.

The engine used on the 30 cwt. chassis has a bare and stroke of 3R ins. and 5 ins. respectively. It 'is classified as a 35 hp., and is of the four-eylindered L head type, with the cylinders cast en bloc. The cylinder heads form a separate casting, thus permitting uniformity in the cylinder cares and less liability of initial stresses. The crankcase is an aluminium casting, whilst the lower half is made of pressed. steel and is easily removable, rendering the bearings very accessible.

An interesting detail in the design is that the inlet and exhaust valves are interchangeable. They have nickel steel heads electrically welded to carbon steel stems, and the ends a these stems are hardened to resist wear owing to the tappet action. Each piston is fitted with three diagonally-split rings, and in addition has oil grooves turned on its outside.

The gudgeon pins are made of steel tnlaing, hardened and ground to size. They are held firmly in the piston bosses, phosphor-bronze bushes being pressed into the connecting rods. The camshaft is a drop forging, 1k„ ins, diameter with integral cams, and ,lubricated by oil which collects in oil pockets cast for this purpose in the crankcase. Three hearings are provided for the crankshaft; these are all of white metal held in phosphor-bronze

For lubrication a -combination of forced feed and splash is employed, a horizontal plunger pump beingdriven from an eccentric on the camshaft ; this pump forces oil to the timing gears and also over the front and rear main bearings. The middle crankshaft bearing, the pistons and the connecting rods-are lubricated by splash. Magneto ignition is incorporated, and the timing of this is fixed in order to simplify the driving.

The thermo-syphonic system is used for water circulation, and the radiator is, of the cast header and bottom tank type with a centre composed of copper tubes. A fan driven by a V pulley assists\ the cooling effect. Theengine, clutch, and gearbox are arranged on the unit system. The clutch is of the dry plate, multiple-disc type with four plain steel plates and rive asbestos lined. Three speeds and a reverse are provided by the gearbox; all the gears have a tooth width of in., and are case-hardened. The primary shaft and counteeshaft are of chrome nickel steel, and are provided with annular ball bearings.The propeller shaft is in two sections, embodying three -universal joints and a splined slip joint to allow for the backward and forward movement of the rear axle.

The cardan joints are of the star type, and are adequately protected from the entry of dirt and water by sheet steel covers and pressed steel, hemispherical . dust, caps; the latter are pressed into contact with the covers bylight spiral springs. The centre joint, together with the brake drum, is supported in a selfaligning ball bearing suspended in a housing attached to a cross member.

The back. axle is of the interesting type in which the load is carried by a solid axle, and the driving is done by a built-up axle, the final drive being by internal gears. The particulat axles fitted' to the Stewart lorries are of Clark make.

The frame is perfectly straight, and of deep section, and the wheels are of the wood artillery type fitted with single solid tyres throughout ; incidentally, twin tyres are fitted to the rear wheels of the laeavid models.'

The braking is 'adequate, the foot brake having e:erticularlv wide shoes lined with bora:fed asbesto`s. The hand b-rake operates on the rear wheels through the medium of bands which contrait on to the exteriors of the internally toothed rings. The front axle is of the ordinary drop forged type, 2 ins. wide and 2i ins. deep. -The steering knuckles are excep; tionally large, and are forged from nickel 18 S.W.G. sheet steel, all the seams and joints being welded. It is coated on the inside and outside with a special material which prevents rust or corrosion through the action of the petrol. The capacity Of 64 tank is 16 gallons, audit is located under the driver s seat. The loading space has a length of 9 ft., and a width of 45 ins. but the vehicle is Bold as a chassis only, and. ,purchasers must fit their own bodies. ,

Careful attention has been paid to the question of springing. The front springs are 40 ins, long and"2 ins. wide, ;whilst the rear springs are 54 ins. long and 3 ins. wide. Both the. front and rear springs are fitted 'withrebound 'plates, the second leaf of each spring being tho main one and being turned over at the ends to form the spring eyes.

Noteworthy features about the rear axle are that it &rives exceptional ground clearance, is considerably lighter than the ordinary type, and can be made with a smaller differental because the Chief gear reduction is between the internal gears of the final drive.

The company can give very quick delivery of any of the Stewart models, and inquiries should be forwarded to the London office, the address of which we gave at the commencement of the article.