New 'Walker 5-tonner for Overseas

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

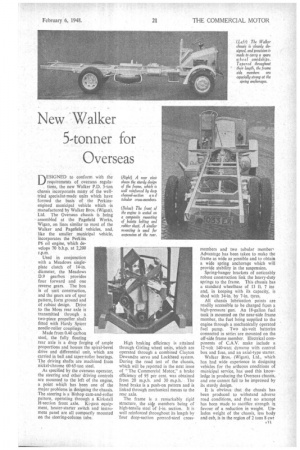

DESIGNED to conform with the requirements of overseas reguIa. tions, the new Walker P.D. 5-ton chassis incorporates many of the welltried specialist-made units which have formed the basis of the Perkinsetigined municipal vehicle which -is manufactured by Walker Bros. (Wigan), Ltd. The Overseas chassis is being assembled at the Pagefield Works, Wigan, on lines similar to most of the Walker and Pagefield vehicles, and, like the smaller municipal vehicle, incorporates the Perkins P6 oil engine, which develops 70 b.h.p. at 2,200 r.p.m.

Used in conjunction with a Meadows singleplate clutch of 14-in. diameter, the Meadows D.9 gearbox provides four forward and one reverse gears. The box is of unit construction, and the gears are of spur pattern, form ground and of robust design. Drive to the Moss rear axle is transmitted through a two-piece propeller shaft fitted with Hardy Spicer needle-roller couplings.

Made from 0.40 carbon steel, the fully floating rear axle is a drop forging of ample proportions and houses the spiral-bevel drive and differential unit, which are carried in ball and taper-roller bearings. The driving shafts are machined from nickel-chrome 60-65-ton steel, As specified by the overseas operator, the steering and other driving controls are mounted to the left of the engine, a point which has been one of the major problems in designing the chassis. The steering is a Bishop cam-and-roller pattern, operating through a Kirkstall H-section front axle. Ki-gass equipment, heater-starter switch and instrument panel are all compactly mounted on the steering-column tube. High braking efficiency is attained through Cirling wheel units, which are operated through a combined Clayton Dewandre servo and Lockheed system. During the road test of the chassis, which will be reported in the next issue of "The Commercial Motor," a brake efficiency of 95 per cent. was obtained from 20 m.p.h. and 30 m.p.h. The hand brake is a push-on pattern and is linked through mechanical means to the rear axle.

The frame is a remarkably rigid structure, the sicte members being of high-tensile steel of 4-in. section. It is well reinforced throughout its length by four deep-section pressed-steel cross

members and two tubular members Advantage has been taken to make the frame as wide as possible and to obtain a wide spring anchorage which will provide stability in the suspension.

Spring-hanger brackets of noticeably robust construction link the heavy-duty springs to the frame. This chassis has a standard wheelbase of 13 ft. 7 ins and, in keeping with its capacity, is shod with 34-in. by 7-in. tyres.

All chassis lubrication points are readily accessible to be charged funn a high-pressure gun. An 18-gallon fuel tank is mounted on the near-side frame member, the fuel being supplied to the engine through a mechanically operated fuel pump. Two six-volt batteries connected in series are mounted on the off-side frame member. Electrical components of C.A.V. make include a 12-volt 140-watt dynamo with control box and fuse, and an axial-type starter.

Walker Bros.(Wigan), Ltd., which has had wide experience in designing vehicles for the arduous conditions of municipal service, has used this knowledge in producing the Overseas chassis, and one cannot fail to be impressed by its sturdy design.

It is obvious that the chassis has been produced to withstand adverse road conditions, and that no attempt has been made to sacrifice strength in favour of a reduction in weight. Unladen weight of the chassis, less body and cab, is in the region of 2 tons 8 cwt