I.—C. ENGINE VALVES.

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

Some Instructive Contributions from Our Driver and Mechanic Readers.

T"E"s. prize is awarded this week to " D.W.R.," of Bradford-onAvon. He sends us an ingenious slag* gestian for 'a spacer for the valves and tappets of the Ford car, van, or lorry. At least, he puts the suggestion forward in that way, although it is obviously of value in. connection with any engine which has no means of adjustment for the clearance between the valves, and tappets.

Take a piece of On, sheet steel,

ins, long by ins, broad, and drill eight 5-16 in. holes in it, spaced as indicated in the sketch, namely, with the line of centres f in. from one longitudinal edge, and with the holes equally spaced along that line,.

Heat the metal and bend it, along its centre-line until double, as shown. Then cut into eight equal pieces, with a hole in each. The pieces thus formed make :admirable spacers for the valves. They can .be fitted quite easily, without disturbing the cylinder head. All that is necessary is to lift the valves, using the ordinary valve lifter and applying it under the spring-retaining pin, and slip

the packing piece in place. if it is too thick, as is very likely, it must be filed down on the plain, flat side until, when it is in plate, the clearance between valve and stem, with the engine cold, is 1-32 in

"W.H.T.," of Bradford, Yorks., had trouble with a broken exhaust valve, it had broken at the junction between head . and stern, and had been run in that condition for a time not for long, but long enough to get the valve seat into such a state that it was necessary to reface it. Our correspondent was without any tool with which ho could do the refacing; and it was not considered to be worth while to purchase one especially for the job. He therefore set about making one from the available material, procured, as is generally the case, from the scrap. heap.

The actual cutting tool was made from a small file, section * in. by 3-16 in. This was carefully made, and the cutting edge ground to the correct angle for facing the seat. The spindle of the actual broken valve was utilized as a cutter bar, and the tool made a good fit in the cotter hole. When so located, the cutting edge 'projected from the spindle an amount equal to the radius of the valve, and was thus ready for use.

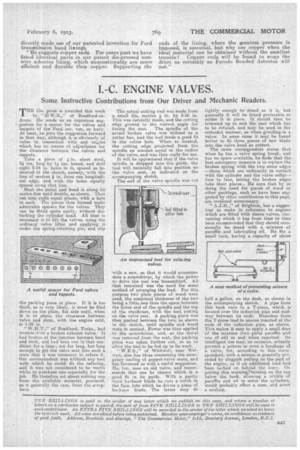

It will be appreciated that if the valve spindle is dropped into the guide, the tool will naturally fall into position on the valve seat, as indicated on the ' accompanying sketch. The end of the valve spindle was cut

with a saw, so that it would accommodate a screwdriver, by which the power to drive the tool was transmitted._ All that remained was the need for some method of arranging the feed. For this purpose two plain pieces of wood were used, the combined thickness of the two being a little less than the space between the lower end of the spindle and the top of the crankcase, with the tool resting on the valve seat. A packing piece was then pushed between the two, as shown in the sketch, until spindle arid wood were in contact. Power was then applied to the screwdriver, and, as the metal was removed from the seat, the packing piece was taken further out, so as to allow the tool to be fed up to its work. " of Whitwell, near Welwyn, also has ideas concerning the mei.; gency tooling of poppet-valve seats, and. has favoured us with a useful suggestion. He, too, uses an old valve, and recommends that one be chosen which is a good fit in its guide. With a partly worn hacksaw blade he cuts a notch in the face, into which he drive a Piece of hacksaw black. The latter may fit

tightly enough to stand as it is, but generally it will be found preferable, to solder it. in place. It should then be trimmed up to suit the seat which has to be refaced, and may be used in the orthodox manner, as when grinding-in a valve, in some cases it may be found better to fit three pieces of saw blade into the valve head as cutters.

The same correspondent states that when he has a valve spring break, and has no spare available, he finds that the best emergency measure is to replace the broken spring with the two outer edges —those which are ordinarily in contact with the cylinder and the valve collar— face to face, letting the broken edges take their places. He says that by so doing the need for pieces of, wood or other packings, such as have been suggested by other contributors to this page, are rendered unnecessary.

" of Brighton, has a suggestion to make in reference to engines which are fitted with sleeve valves, concerning which it. has from time to time been recommended that they should occ.asionally bei dosed with a mixture of paraffin and lubricating oil. He fits a small tank, having is capacity of about half a gallon, on the dash, as shown in the accompanying sketch. A pipe from this tank runs to a. T'-piece, which is located over the induction pipe and midway between its ends. Branches from the T-pieee lead to unions inserted at the ends of the induction pipe, as shown. This makes it easy to apply a small dose of the mixture (two parts paraffin and one of oil) as and when required. its intelligent use may, on occasion, actually prevent a seizure or even a breakage of a valve, for, according to this correspondent, such a seizure is generally peeceded by sluggish pulling on the part of the engine, as if an additional load had been tacked on behind the lorry. On getting this Nvarning,*turning on the tap below the tank, allowing a trickle of paraffin and oil to enter the cylinders, would probably effect a cure, and avert a mishap,