PATENTS SUMMARIZED.

Page 32

If you've noticed an error in this article please click here to report it so we can fix it.

Introducing Steam Into a Petrol Engine.

C. B. Olson, of 1919, South Michigan Avenue, Chicago, Illinois, describes, in specification No. 110,416, a method of introducing dry steam with the mixture of petrol and air, or paraffin and air into an internal-combustion engine.

A small water tank is clipped to the exhaust manifold by any suitable means. The tank, which is shown in section in the drawing which we reproduce from the specification, is fitted with three ball valves. • That-on the right-isamerely a back-pressure valve, which prevents the steam returning to the tank. In the centre is a safety valve, which is carried in, the filler cap of the tank. That on the left is arsnifting valve.; it allows air to enter as the steam is withdrawn. All three valves are spring controlled, the tension of each spring being easily adinstable. The left-hand valve, besides acting as stated above, also performs, in some degree, the function of a control valve. It may be left almost free to open, so that the least degree of suction in the tank will cause air to enter. It will, in these circumstances, be necessary for the temperature of the water to rise to 100 degrees Centigrade, the boiling point of water at atmospheric pressure, before steam commences to be induced with the explosive charge.

The delivery pipe from the tank is of small bore, and it is wrapped many times round the exhaust manifold, forming a coil. In this manner superheating of the steam is arranged, and in consequence it issues to the engine cylinders in a perfectly dry state.

Another Heavy Fuel Vaporizer.

A. S. Hickox, an American citizen, of Ilopland, Mendocino, California, describes fn specification No. 110,431 a very complete outfit for the carburization end vaporization of heavy oils like kerosene and, coal or tar oils. The device would be more correctly described as a two-fuel carburetter, inasmuch as it provides for starting on petrol, and switching over to the heavier fuel when the engine has warmed up. The details of the invention have been carefully worked out, and everything,

down to the three-way cock which• controls the fuel supply, is most clearly described in the specification. Naturally, the most important detail is the heater axd vaporizer. This is an exhaustheated jacket which entirely surrounds the whole of the induction pipe. The exhaust gas is conducted to this jacket through a branch pipe from the engine. manifold, a second pipe leading the gases from the jacket back to a point in the exhaust pipe nearer to the silencer. Between these two pipes, in the exhaust manifold, is placed a butterfly valve, by. means of which the quantity of gas which is being ly-passed through the jacket may be regulated.

A water tank is carried on the dash, a pipe leading therefrom to the induction manifold. In the pipe is fitted a needle valve, which is oontvolled by a hand wheel and sorew. In this manner a small quantity of water, can be provided, to be taken. into each combustion chain her with the mixture.

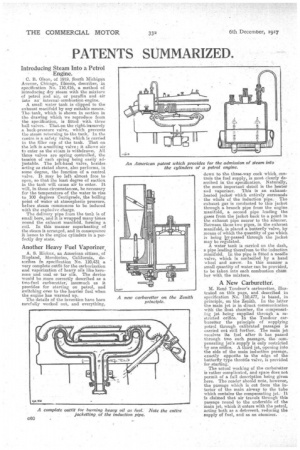

A New Carburetter.

M. Rea Tondeur's carburetter, illustrated on this page, and, described in specification No. 110,477, is based, in principle, on the Zenith. In the latter the Main jet is in direct communication with the' float chamber, the compensating jet being supplied through ' a restricted orifice. In the Tondeur carburetter the principle of supplying petrol through calibrated passages is carried ou%. still further. The main jet receives its fnel after it has passed through two such passages, the compensating jet's supply is only restricted by one orifice. A third jet, opening into the side of the main induction passage, exactly opposite to the edge of the butterfly type throttle valve, is presided for starting. The actual working of the carburetter is rather complicated, and space does not permit of a full description being given here. The reader should note, however, the passage which is cut from the interior of the main airway to the tube which contains the compensating jet. It is claimed that air travels through this passage round to the underside of the main jet, which it enters with the petrel, acting both as a deterrent, reducing the supply of fuel, and as an atomiser.