For DRIVERS, MECHANICS & FOREMEN.

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

PRIZE OF TEN .SHILlittirGS is awarded each week to the sender of the best letter which we publish on this page ; all others are paid for at the rate of a penny a lane, with an allowance for photographs, All notes are edited before bang -ublished. Mention vowemployer's name, in confidence, as evidence of good faith, Address, D., M. and P., "The Commercial Motor," 7-15, Rosebery Avenue, London, E.G. I.

Lamps Alight—

Light your lamps at 4.3 in London, 4.40 in Edinburgh, 4.10 in Newcastle, 4.24 in Liverpool, 4.25 in Birmingham, 4.33 in Bristol, and 5.8 in Dublin.

Front Axle Wear on a Steam Wagon.

The sender of the following communication has been awarded the 108. prize this week.

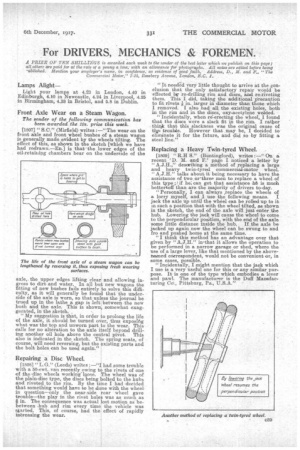

[1807] "5.0." (Mirfield) writes :—" The wear on the front axle and front wheel bushes of a steam wagon is generally made evident by the wheels tilting. 'The effect of this, as shown in the sketch [which we have had redrawn.—En.] is that the lower edges of the oil-retainipg chambers bear on the underside of the axle, the upper edges lifting clew] and allowing ingress to dirt and water. In all but new wagons the fitting of new bushes fails entirely to solve this difficulty, as it will generally be found that the underside of the axle is worn, so that unless the journal be trued up in the lathe a gap is left between the new bush and the axle. This is shown, somewhat exaggerated, in the sketch.

"My suggestion is that, in order to prolong the life of the axle, it should be turned over' thus exposing what was the top and unworn part to the wear. This calls for no alteration to the axle itself beyond drilling another oil hole above the central pivot. This also is indicated in the sketch. The spring seats, of course, will need reversing, but the existing parts and the bolt holes can be used again." ,

Repairing a Disc Wheel.

[1808] " L.G." (Leeds) writes :—"I had some trouble with a 50-cwt. van recently owing to the rivets of one of the, disc wheels working loose. The wheel was of the plain-disc type, the discs being bolted to the hubs and riveted to the rim. By the time I had decided that something would have to be done with the wheel in question—only the near-side rear wheel gave trouble—the play in the rivet holes was as much as

in. The consequence was actual lost motion as bebetween .hub and rim every time the vehicle was started. This, of course, had the effect of rapidly mbreasing the wear.

"It needed very little thought to arrive at the conclusion that the only satisfactory repair would be effected bpre-drilling rim and discs, and re-riveting them. This I did, taking the additional Precaution to fit rivets in. larger in diameter than those which I removed. I also had all the existing holes, both in the rim and in the discs, oxy-acetylene welded. "Incidentally, when re-erecting the wheel, I found that the discs were a slack fit in the rim. I ratlier think that this slackness was the original cause of thtei trouble. However that may be, I decided to eliminate it for the future, and did so by fitting a steel line."

Replacing a Heavy Twin-tyred Wheel.

[1809] "R.H S." (Buntingford), writes :—" On a recent 'D. M. and. F.' page I noticed a letter by " A.J.H.," desoribing a method of replacing a large and heavy twin-tyred commercial-motor wheel. " A.J.H." talks about it being necessary to have the assistance of two or-three men to replace a wheel of this type ;? if he can get that assistance lit is much bettertoff than are the majority of drivers to-day. "Personally, I can always ,replace the wheels of a lorry myself, and J use the following means. I jack the axle up until the wheel can be rolled -up to it in such a position that with the wheel tilted, as shown in the sketch, the end of the axle will just enter the hub. Lowering the jack will cause the wheel to come to the perpendicular position, with the end of the axle some little distance inside the hub. If the axle be jacked up again now the wheel can be swung to and fro and pushed home at the same time.

"I think this method has an advantage over that given by "A.J.H." in-that it allows the operation to be performed in a narrow garage or shed, where the use of a large lever, like that mentioned by the abovenamed correspondent, would not be convenient or, in some cases, possible.

"Incidentally, I might mention that the jack which I use is a very useful one for this or any similar purpose. It is one of the type which embodies a lever and pawl. The manufacturer is the Duff Manufacturing Co, Pittsburg, Pa., 'U.S.A."