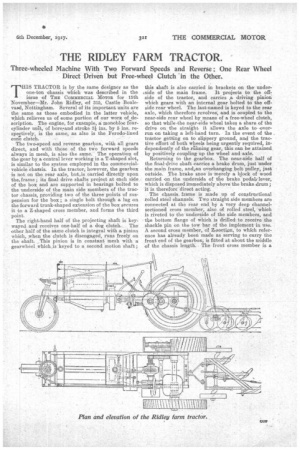

THE RIDLEY FARM TRACTOR.

Page 19

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

Three-wheeled Machine With Two Forward Speeds and Reverse ; One Rear Wheel Direct Driven but Free-wheel Clutch -in the Other.

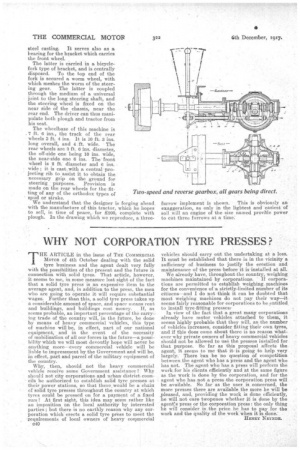

THIS TRACTOR is by the same designer as the one-ton chassis -which was described in the issue of TEE COMMERCIAL MOTOR for 15th November—Mr. John Ridley, .of 316, Castle Boolevaikel, Nottingham. Several of its important units are the same as those embodied in the latter vehicle, which relieves us of some portion of our worn of description. The engine, for example, a rnonobloc furcylinder unit, of bore!and stroke 3± ins. by 5 ins. respectively, is the same, as also is the Ferodo-lined cone clutch. , The two-speed and reverse gearbox, with all gears direct, and with those of the two forward speeds always in mesh, is also the same.' The operation of the gear by a central lever working in a T-shaped slot, is similar to the system employed in the commercialvehicle chagsis. In the tractor, however, the gearbox is not on the rear axle, but,is carried directly upon the, frame ; its final drive shafts project at each side of the box and are supported in bearings bolted to the underside of the main side members of the tractor chassis, providing two of the three points of suspension for the box a a single bolt through a lug on the forward trunk-shaped extension of the box secures it to a Z-shaped cross member, and forms the third point. The right-hand half of the projecting shaft is key-: wayed and receives one-half of a dog clutch. The other half of the same clutch is integral with a pinion which, when the clutch is disengaged, runs freely on the shaft. , This pinion is in constant mesh with a gearwheel which_is 'keyed to a second motion shaft ; this shaft is also carried in brackets on the under 4side of the main frame. It projects to the off side of the tractor, and carries driving pinion which gears with an internal gear bolted to the offside rear wheel. The last-named is keyed to the rear axle, which therefore revolves, and is coupled to the near-side rear wheel by means of a free-wheel clutch, so that while .the near-side wheel takes a share of the drive on the straight it allows the axle to .over. run on taking a left-hand turn. In the event of the tractor getting on to slippery ground, and the tractive effort of both wheels being urgently required, independently of the running gear, this can be attained by positively coupling up the wheel and axle.

Returning to the gearbox.. The near-side half of the final-drive shaft carries a brake drum, just under the main frame, and,an overhanging belt pulley, just outside. The brake. aloe is merely a block of wood carried on the underside of the brake pedaLcIever, which is disposed immediately above the brake drum ; it is therefore direct acting.

The chassis, frame is made up of con,structional rolled steel channels. Two straight side members are connected at the rear end, by a very deep channelsectioned cross member, also of rolled steel, which is riveted to. the underside of the side members, and the bottom flange of which is drilled to receive the shackle pin on the tow bar of the implement in use. A second cross member, of §ion, to which reference has already been made as serving to carry the front end of the gearbox, is fitted at about the middle of the chassis length. The front cross member is a steel casting. It serves also as a

bearing for the bracket which carries the front wheel. - The latter is carried in a bicyclefork type of bracket, and is centrally disposed. To the top end of the fork is secured a worm wheel, with which meshes the worm of the.steer ing gear. The latter is coupled through the medium of a universal joint to the long steering shaft, and the steering wheel is fixed on the near side of the chassis, near the rear end. The driver can thus manipulate both plough and tractor from his seat.

The wheelbase of this machine is . 7 ft. 6 ins., the track of the rear

• wheels 3 ft. 4 ins, it is 10 ft. 3 ins. long overall, and 4 ft. wide. The rear wheels are 3 ft. 6 ins. diameter, the off-side one being 10 ins, wide, the near-side one 6 ins. The' front wheel is 2 ft. diameter and 6 ins. wide ; it is cast with a central projecting rib to assist it to obtain the necessary grip on the ground for steering purposes. Provision is made on the rear wheels for the fitting of any of the orthodox types of spud or strake.

We understand that the designer is forging ahead with the manufacture of this tractor, which he hopes to sell, in time of peace, for 2200, complete with plough. In the drawing which we reproduce, a three

furrow implement is shown. • This is obviously an exaggeration, as only in the lightest and easiest of soil will an engine of the size named provikle power to cut three furrows at a time: