• THE UPKEEP OF STEAM WAGONS.

Page 15

Page 16

If you've noticed an error in this article please click here to report it so we can fix it.

No. 3.—Steam Production and the Perfect Combustion of Fuel in the Firebox.

TO GET THE BEST running results from the wagon, the driver must understand the functions of the various parts of the machine. Steam Production.

The first function is the production of steam in the boiler, and to understand this thoroughly it is necessary to grasp the fact that the boiler converts the heat given out by the burning fuel into mechanical energy or power, in the form of steam under high pressure. Therefore, the main principle is to get perfect combustion of the fuel in the firebox, and this requires (1) a sufficient quantity, of air, (2) air and gases from the fuel to be well mixed, and (3) the mixture to be at a high temperature. The heat is caused by the carbon in the fuel conabining with the oxygen in the air and forming carbon-dioxide gas.

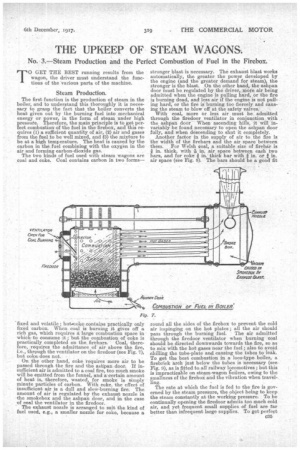

The two kinds of fuel used with steam wagons are coal and coke. Coal contains carbon in two forms— 'fixed and volatile ; but,Peokecontains practically only fixed carbon. When coal is burning it gives off a rich gas, which requires a large combustion space in whiCh to Consume it ; but the combustion of coke is practically completed on the firebars. Coal, therefore, requires the admittance of air above the fire, i.e.' through the ventilator on the firedoor (see Fig. 7), but coke. does not.

On the other hand, coke requires more air to be passed through. the fire and the ashpan door. If insufficient air is admitted to a coal fire, too Much smoke will be emitted from the funnel, and a certain amount of heat is, therefore, wasted, for smoke is simply minute particles of carbon. With coke, the effect of insufficient air is a dull and slow-burning fire. The amount of air is regulated by the exhaust nozzle in the smokebox and the ashpan door, and in the ease of coal the ventilator in the firedoor.

The exhaust nozzle is arranged to suit the kind of fuel used, e.g., a smaller nozzle for coke, because a stronger blast is necessary. The exhaust blast works automatically, the greater the power developed by the engine (and the greater demand for steam), the stronger is the blast,. On the other hand, the ashpan door Must be regulated by the driver, more air being admitted when the engine is pulling hard, or the fire is burning dead, and less air if the engine is not pulling hard", or the fire is burning too fiercely and caus ing the steam to blow off at the safety valves. • With coal, more or less air must be admitted through the firedoor ventilator in conjunction with the ashpan door When ascending hills, it will invariably be found necessary to open the ashpan door fully, and when descending to shut it completely.

Another factor in the supply of air to the fire is the width of the firebars and the air space between them. For Welsh coal, a suitable size of firebar is

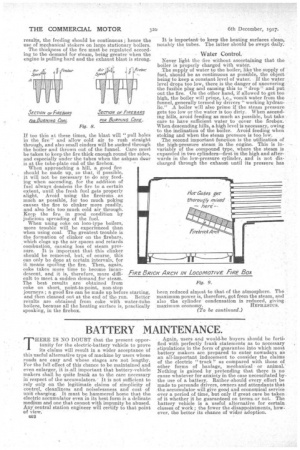

in. thick, with-r-6 in. air space between each two bars, and for coke in. thick bar with I in. or I hi. air space (see Fig. 8). The bars should be a good fit round all the sides of the firebox to prevent the cold air impinging on the hot plates ; all the air should pass through the burning fuel. The air admitted through the firedoor ventilator when burning coal should be directed downwards towards the fire, so as to mix with the hot gases near the fuel; also to avoid chilling the tube-plate and causing the tubes to leak. To get the best combustion in a loco-type boiler, a firebrick arch just below the tubes is necessary (see• Fig. 9), as is fitted to all railway locomotives; but this is impracticable on steam-wagon toilers, owing to the smallness of the firebox and the vibration when travelling.

The rate at which the fuel is fed to the fire is governed by the steam pressure, the object being to keep the steam constantly at the working pressure. To be continually opening the firedoor admits too much cold air, and yet frequent small supplies of fuel are far better than infrequent large supplies. To get perfect

results, the feeding should he continuous ; hence the use a mechanical stokers on large stationary boilers.

The thickness of the fire must be regulated according to the demand for steam, being greater When the engine is pulling hard and the exhaust blast is strong.

If too thin at these times, the blast will " pull holes in the fire" and allow cold air to rush straight through, and also small cinders will be mucked through the boiler and thrown out of the funnel. Care must be taken to keep the fire thick enough round the sides, and especially under the tubes when the ashpan door is at the tube-plate end of the firebox.

When approaching a hill, a good fire should be made up, so that, if possible, it will not be necessary to do any feeding when ascending, for the addition of fuel always deadens the fire to a certain extent, until the fresh fuel gets properly alight. Avoid using the &mons as much as possible, for too much poking causes the fire to clinker more readily, and also lets too much cold air through. Keep the fire in good condition by judicious spreading of the fuel.

When using coke on loco-type boilers, more trouble will be experrenced than when using coal. The greatest trouble is the formation of clinker on the firebars, which clogs up the air spaces and retards combustion, causing loss of steam pressure. It is important that this clinker should be removed, but of course, this can only be done at certain intervals, for it means spoiling the fire. Then, again, coke takes more time to become incandescent, and it is, therefore, more difficult to meet a sudden demand for steam. The best results are obtained from coke on short, point-to-point, non-stop journeys; a good fire can be made up before starting, and then cleaned out at the end of the run. Better results are obtained from coke with water-tube boilers, because all the heating surface is, practically speaking, in the firebox.

It is important-to keep the heating surfaces clean; notably the tubes. The latter should be swept daily.

• Water Control.

Never, light thefire without ascertaining that the boiler is properly charged with water. .The supply of water to the boiler, like "the supply of fuel, should be as continuous as possible, the object being to keep a constant level of water. If the water level drops too low, there is the danger of uncovering the fusible plug and causing this to " drop " and put out the fire. On the other hand, if allowed to get too high, the boiler will prime, i.e., vomit water from the funnel, generally termed by drivers "working hydraulic." A boiler will also prime if the steam pressure gets too low or the water is too dirty. When ascending hills, avoid feeding as much as possible, but take care to have sufficient water to cover the firebox. When descending hills, a, high level is necessary, owing to the inclination of the boiler. Avoid feeding when stoking and when the steam pressure is too low. . The second important function is the utilization of the high-pressure steam in the engine. This is invariably of the compound type, where the steam is expanded in two cylinders—first in the high and afterwards in the low-pressure cylinder, and is not discharged through the exhaust until its pressure has been reduced almost to that of the atmosphere. The maximum power is, therefore, got from the steam, and also the cylinder condensation is reduced, giving maximum economy. HEPHIESTCS.