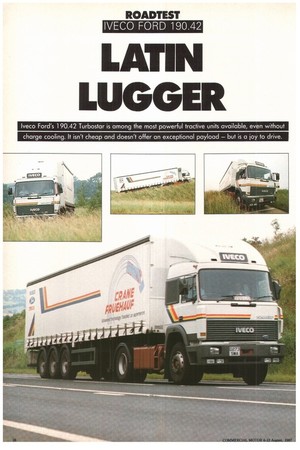

LATIN LUGGER

Page 30

Page 31

Page 32

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

• Iveco Ford's Turbostar 190.42 has more torque, over a wider engine speed range, than any other tractive unit available in the UK. Its 17.2-litre capacity engine, in vee-eight configuration, achieves an installed power output of 309kW (430hp) at a relaxed 1,800rpm and massive torque of 1,898Nm (1,4001bft) at only 1,100rpm. Its twin turbochargers, one on each bank of cylinders, are more responsive than a single one of equal capacity. With the possibility of a higher degree of turbocharging, or the introduction of charge cooling, it is clear that this power unit has even greater potential yet to be realised.

Do operators really want more performance? If MAN's order book for the 470 is to be believed, the answer is yes. The benefits of any such development will need to be measured in terms of overall cost and payback from reduced fuel consumption and the improved journey times which might be provided. In the meantime, the 19(142 Turbostar is one of a handful of 300kW-plus tractors available, and one of the most highly specified. The question is, does its performance match its looks and specification?

• PERFORMANCE

To see how well the 190.42 performs, it must be compared with other highpowered machines. Only the Mercedes 1644 is in the same class, producing slightly more power but slightly less torque from a smaller, 14.6-litre turbocharged but charge-cooled vee-eight power unit.

Overall, the Mercedes-Benz is slightly more economical, averaging 40.411t/100km (7.0mpg) compared with the Turbostar's 41.01it/100km (6.9mpg), but marginally slower at an average 73.0km/h (45.4mph) compared with the 73.21an/h (45.53mph) of the Turbostar.

The high-torque concept gives rise to a more relaxed mode of driving with fewer gear changes. At cruising speeds, engine revs are slower as well, contributing to lower noise levels and improved longevity.

Our best acceleration times, recorded while containing engine speed within the 1,100-1,600rpm green band, though busier through the gears, were faster than we achieved using a larger slice of the power range.

On the road, with acceleration in hand to out-perform most other commercial traffic, there were few occasions where we ventured outside of the green segment. On the motorway once in top gear, other gears became almost redundant. We climbed over Shan heading north at an impressive 881cm/h (55mph) and took only half a gear on Brough. Motorway speeds can be maintained indefinitely at an easy 1,475rpm and need only to drop down to just about 1,200rpm to maintain maximum speed on dual carriageways, still comfortably above maximum torque.

Fuller does not yet offer its twinsplitter gearbox to match the enormous torque of the Fiat vee-eight engine. Instead, a 13-speed constant mesh box with a direct top is specified in conjunction with a Rockwell high-ratio, single-reduction, hypoid axle — reminders of the nowextinct Ford Transcontinental.

Over the timed hillclimbs the 1644 appeared to be generally quicker but we were left with the impression that the Turbostar might have improved upon its performance had we dropped an extra half a gear and made fuller use of the power available, rather than allowing the engine to pull strongly at lower revs.

If there is a weak link in the power train, it is the single-plate clutch. On our first attempt to make a restart on the MIRA (20%) 1-in-5 test hill we failed. The clutch slipped, but held the vehicle stationary. Trying a second time with difflock engaged we were able to pull away by feeding the clutch in more slowly. In general the Fuller Multimesh gearbox was a joy to use. In the top range the split gears are downwards and we found that having to select fifth-high before descending through the range change to direct fourth is an unnecessary complication in the sequence.

• BRAKING

Braking gave us problems too. From the first slow speed maximum braking stop it was clear that the drive axle was locking up long before the front axle. At 48km/h the degree of instability worsened, and at 641crn/h we were forced to abort the braking stop to avoid a full jacknife. On a dry clear track we had both time and room to do so — in a real-life situation there may not be. Peak decelerations show that the twin-wedge brakes operating on fully floating shoes are capable of providing satisfactory performance, but greater attention should be given to obtaining a more compatible front-to-rear ratio in relation to stability.

All was not well on the road when using the exhaust brake, either. The twin butterfly valves proved to be efficient enough in checking vehicle speed on long downhill gradients but the problem arose when selecting a lower gear to provide increased retardation. The initial application of the exhaust brake foot valve pushes the fuel rack back and holds it, cutting off the feed to the engine. lithe clutch is then dipped to select a lower gear, without first touching the accelerator, the engine stops and power steering is lost. We had a similar experience two weeks before with the new 190.36 Turbostar.

• HANDLING

The cab's four-point suspension combines with the chassis parabolic springs front and rear and the lsringhausen air suspension seats to give a very comfortable ride. Even with the seat suspension locked out, the remaining suspension was adequate for almost all occasions.

Front and rear cab suspension points, mounted a long way apart, prevent any suggestion of pitching moment but the overhang on either side contributes to the large degree of cab roll when negotiating any but the shallowest bends. Once the driver became accustomed to this aspect of the vehicle's handling it had little influence on steering or journey times.

With our regular semi-trailer in for ser vice, we made use of Iveco Ford's Crane Fruehauf air-suspended tri-axle trailer which can only have improved the overall ride characteristics.

• CAB COMFORT

If the Turbostar is outstanding for anything other than its high-torque engine, it is the number of items it incorporates as standard features. It has a roof-mounted spoiler; the steering wheel can be adjusted through 10° of rake and 100mm of height and in the header rail the Italian engineers have incorporated lockable radio and CB radio cubicles.

Other lockable compartments are included in the centre console, a wardrobe is sited at the end of the bunk and there is a strongbox bolted through the cab floor beneath the bunk. Windows operate electrically and the large rear-view mirrors not only contain heated elements and have a wash/wipe facility, but can be adjusted remotely from within the cab and can be programmed to assume a preset position.

The air conditioning can renew all the air in the 6.3m3 cab every 50 seconds and the heater with its 13 outlets can raise the in-cab temperature to 22°C while the ambient temperature is as low as —30°C. In addition, an Eberspacher night heater provides heating while the engine is not operating. An electric socket is fitted in the centre of the oddment tray, the passenger's footrest has ratchet adjustment, and the front screen roller blind is full width. There are also side roller blinds to shade the driver from the sun. Curtains all around and in front of the twin bunks ensure privacy.

Vertically louvered windows behind the B-posts add to rearside visibility but full use of the nearside rear view mirror is obstructed by the siting of the kerb mirror.

The driver sits surrounded by a console neatly displaying instruments, warning lights and switches. Gear lever, park brake and difflock controls are positioned close together.

Smart interior trim strikes a good balance between opulence and practicality and should be easy to keep clean. Above: Switches and instrumentation are neatly displayed on the sweeping fascia and all controls are within easy reach. Below the cab, the power-steering pump and compressor are neatly installed at the rear of each set of cylinders.

In addition to three paper cartridge filters, the oil-filtration system, which is designed to prolong engine life, uses a cotton-filled cartridge to remove even the smallest contaminating particles.

SUMMARY

Since October 1984 more than 12,000 Turbostars have gone into service throughout Europe. Now it is available in right-hand drive, sales in the UK will no doubt reflect its established popularity on the Continent.

The high power arid torque output of the large-capacity engine make it one of the easiest vehicles to drive that we have tested. There is little that can be added to the standard specification. Indeed, Iveco Ford lists only alloy wheels and the alternative ZF gearbox as options.

Over fast motorway and easy dual carriageway section where it is able to make the most of its high-torque output at low revs, the Torbostar returns good fuel consumptions at high average speeds.

We are less impressed by the gear sequence, emergency braking and the exhaust brake: all need to be improved. The Turbostar's cab roll was something we came to live with.

Such a large-capacity engine, still relatively lightly stressed, matched to wellproven drive line components (apart from the single-plate clutch) should put the question of reliability beyond doubt. The Turbostar 190.42 is, however, heavy and good payload can't be listed among its attributes.

It is difficult to justify the cost except to say it has everything — and for sheer driving pleasure this unit really will take some beating.

0 by Bill Brock