Don't do the dirty OF

Page 29

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

your filter

— by Trevor Longcroft

:IT'S SURPRISING how often air filters are neglected during the normal service routine. If the filter is not cleaned or changed regularly, according to manufacturer's recommendations, poor fuel consumption, loss of power and smoke are the inevitable results — perhaps sooner rather than later.

On the other hand running without an air filter is courting disaster. It requires only a cupful of dust to reduce an efficient engine into a hulk of useless metal which could cost a fortune to repair.

Coopers Filters are explicit in their explanations how fitters can ensure optimum filter efficiency without detriment to service life. And they have described and given me the relative merits of the different. types of filters that a fitter is likely to come across in the workshop.

Although manufacturers recommend that filters be cleaned or 'replaced at regular intervals depending on service conditions it is tempting to ignore these instructions: the more so, when a visual inspection shows nothing untoward.

Do not be duped! The only sure way to check filter condition is to use a service indicator or vacuum gauge and read off the filter restriction.

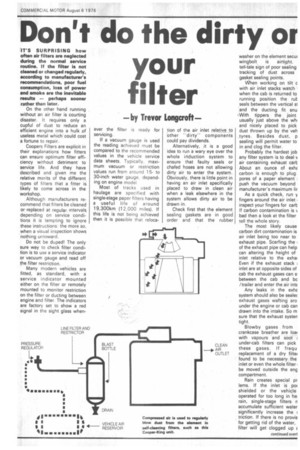

Many modern vehicles are fitted, as standard, with a service indicator mounted either on the filter or remotely mounted to monitor restriction on the filter or ducting between engine and filter. The indicators are factory set to show a red signal in the sight glass when

ever the filter is ready for servicing.

If a vacuum gauge is used the reading achieved must be compared to the recommended values in the vehicle service data sheets. Typically, maximum vacuum or restriction values run from around 15to 30-inch water gauge, depending on engine model

Most of tracks used in haulage are specified with single-stage paper filters having a useful life of around 19,300km (12.000 miles). If this life is not being achieved then it is possible that reloca tion of the air inlet relative to other "dirty" components could pay dividends.

Alternatively, it is a good idea to run a wary eye over the whole induction system to ensure that faulty seals or chafed hoses are not allowing dirty air to enter the system. Obviously, there is little point in having an air inlet specifically placed to draw in clean air when a leak elsewhere in the system allows dirty air to be drawn in.

Check first that the element. sealing gaskets are in good order and that the rubber

washer on the element secui wingbolt is airtight. tell-tale sign of poor sealing tracking of dust across gasket sealing points.

When working on tilt c

with air inlet stacks watch when the cab is returned to running position the rut .seals between the vertical st and the ducting fit snu With tippers the joint usually just above the whi and nicely placed to pick dust thrown up by the veh tyres. Besides dust, p sealing will permit water to in and clog the filter.

Probably the hardest job any filter system is to deal v air containing exhaust cart About an ounce of exhe carbon is enough to plug pores of a paper element push the vacuum beyond manufacturer's maximum hr As a quick check, run y fingers around the air inlet ; inspect your fingers for cart If carbon contamination is N. bad then a look at the filter tell the whole story.

The most likely cause carbon dirt contamination is air inlet being too near to exhaust pipe. Scarfing the of the exhaust pipe can help can altering the height of inlet relative to the exhal Even if the exhaust stack ; inlet are at opposite sides of cab the exhaust gases can si between the cab and bc /trailer and enter the air inte Any leaks in the exhe system should also be sealec exhaust gases wafting aro under the engine or cab can drawn into the intake. So m sure that the exhaust systen tight.

Blowby gases from crankcase breather are low with vapours and soot under-cab filters can pick these gases. If frequ replacement of a dry filtei found to be necessary the inlet or even the whole filter be moved outside the eng compartment.

Rain creates special pr

lems. If the inlet is poi shielded or the vehicle operated for too long in he; rain, single-stage filters n accumulate sufficient water significantly increase the I triction. If there is no provis for getting rid of the water, filter will get clogged up e

the engine will lose power and will smoke.

If the air intake is mounted about level with the cab roof, rain drops can splash into the intake. The best remedy here is to lift -the air intake by as much as a foot or 18 inches beyond splash reach.

Side-mounted air cleaners are sometimes located to conveniently catch any water thrown off by water blades.

The best thing to have too is to raise the intake or, alternatively relocate the filter: One further point: when hosing down a vehicle be careful not to play the hose on the air inlet. Its surprising how much water can be inadvertently played into the filter by a careless fitter.

Air filters can be divided into four main groups; the oil bath; single-stage paper element; two-stage paper; and self-cleaning types.

At its best an oil-bath air cleaner has an efficiency of around 98 per cent. The efficiency of the filter decreases as engine speed diminishes and maximum efficiency is reached at maximum engine speed.

There is a risk with this type of filter of the toreign particles collected in the filter being able to enter the inlet manifold — and as such the system leaves much to be desired.

The single-stage paper element-type filter is constructed in pleated form to maximise paper filter area for the given filter volume. Its efficiency is not restricted by engine speed and the element is simply replaced at the end of its useful life — usually around 19,300km (12,000 miles).

A useful life of around 64,400km (40,000 miles) is expected from two-stage paper element-type filters. They are dubbed "off-highway" filters, and first-stage filtration is carried out by a cyclonic cleaner which effectively induces the induction air to swirl to centrifuge out 80 per cent of the dust particles into a separate bowl.

Other more specialised twostage filters for site vehicles are capable of removing up to 98 per cent of the dust entering the filter before the air reaches the paper element. This on its own, is as good as the oil-bath filter and the air has yet to pass through the final paper element.

The self-cleaning filter is ideally suited to vehicles working in extremely dusty conditions and though the initial outlay is greater the cost is recouped by lower maintenance costs and an element life of up to 15,000 hours.

The Cooper-King self-clean filter has a dense woven wool filter element and each minute a blast of compressed air blows clean one of the eight filter segments.