A Popular EXTENSION UNIT

Page 69

If you've noticed an error in this article please click here to report it so we can fix it.

for Light Goods Chassis

WE have frequently described successfulcessful conversion sets which are available on the British market for the adaptation of four-wheeled chassis so that, with an additional axle, they may carry larger and heavier loads. On page 574 of our issue dated June 4th, for example, we mentioned two or three types of extension unit, the use of which enabled a wood-wool manufacturer to deal with very bulky 2-ton loads, utilizing adapted Chevrolet and Ford 30-cwt. chassis, and, in the heavier class, we treated (on page 531 of our issue dated May 28th) with a method of converting a 4-ton Dennis lorry I..4a that 10 tons could be carried.

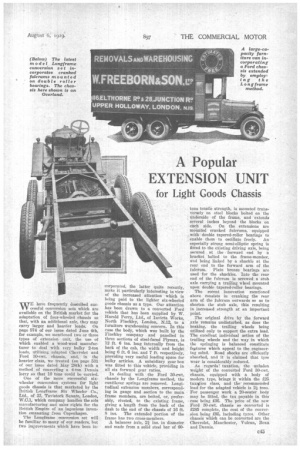

One of the more successful sixwheeler conversion systems for light goods chassis is that marketed by the British Loneframe Six Wheeler Co., Ltd., of 23, Tavistoek Square, London, W.C.1, which company handles the sole manufacturing and sales rights for the British Empire of an ingenious invention emanating from Copenhagen.

The Longframe conversion set will be familiar to many of our readers, but two improvements which have been in

corporated, the latter quite recently, make it particularly interesting in view of the increased attention which is being paid to the lighter six-wheeled goods chassis as a type. Our attention has been drawn to a converted Ford vehicle that has been supplied by W. Harold Perry, Ltd., of Invicta Works, North Finchley, London, N.12, to a furniture warehousing concern. In this ease the body, which was built by the Finchley company and panelled in three sections of steel-faced Plymax, is 12 ft. 6 ins, long internally from the back of the cab, the width and height being 6 ft. 6 ins. and 7 ft. respectively, providing very useful loading space for bulky articles. A subsidiary gear box was fitted to this vehicle, providing in all six forward gear ratios.

In dealing with the Ford 30-evet. chassis by the Longframe method, the cantilever springs are removed. Longitudinal extension members, corresponding in gauge and section to the main frame members, are bolted, or, preferably, riveted, to the existing frame, giving a length from the back of the dash to the end of the chassis of 16 ft. 8 ins. The extended portion of the frame has two cross-members.

A balancer axle, 2f ins, in diameter and made front a solid steel bar of (30

tons tensile strength, is mounted transversely on steel blocks bolted on the underside of the frame' and extends several inches beyond the blocks on each side. On the extensions are mounted cranked fulcrums, equipped _ with double tapered-roller bearings to enable them to oscillate freely. An especially strong semi-elliptic spring is fitted to the existing driving axle, being secured at the forward end by a bracket bolted to the frame-member, and being linked by a shackle at the rear end to the forward arm of the fulcrum. Plain bronze bearings are used for the shackles. Into the rear end of the fulcrum is screwed a stub axle carrying a trailing wheel mounted upon double tapered-roller bearings.

The recent innovation mentioned above consists in cranking the rear arm of the fulcrum outwards so as to shorten the stub axle, this resulting in increased strength at an important point.

The original drive by the forward axle remains undisturbed, as does the braking, the trailing wheels being utilized only to support the extra load. The excellent individual action of the trailing wheels and the way in which the springing is balanced constitute features which appeal to the engineering mind. Road shocks are efficiently absorbed, and it is claimed that tyee wear is considerably reduced.

As regards': taxation, the unladen weight of the converted Ford 30-ewt. chassis, equipped with a body of modern type, brings it within the £25 taxettion class, and the recommended load for the adapted vehicle is 2i tons. For passenger work a 20-seater body may be fitted, the tax payable in this case being £36. The price of the new Ford 30-cwt. chassis so converted is £285 complete, the cost of the conversion being £05, including tyres. Other chassis which can be converted are the Chevrolet, Manchester, Vulcan,. Bean and Dennis.