Tipper body in cab for two pins

Page 73

Page 74

Page 75

If you've noticed an error in this article please click here to report it so we can fix it.

Three-way tippers offer substantial a antages for operators-but

the sys-em ts Achilles heel, Graham Montgomerie repot

iREE-WAY tipping gears are ry useful when a load is to be opped in an awkward place iere manoeuvring the vehicle tip to the rear is impossible. r this reason, the municipal ctor is the three-way system's Nest customer.

On the Continent, however, ? system is very popular and es not just depend on local thorities for success. I have en talking to Edbro about the sign and operation of such a out as well as about the adntages and disadvantages.

edition As far as the UK tipping gear irket is concerned, Edbro curitly accounts for about 80 per It. Of that figure, less than 10 r cent of the tipping gears sold ! of the three-way variety. In rope however, the reverse D lies.

Taking Germany as a specific Imple, over 80 per cent of the pers are three-way and the ne applies to Holland. Much his is just tradition of course, owing the way -the market ;.always gone". As an aside, iimilar situation applies with ;es — on the Continent, the iculated bus is popular, ereas the UK has a long dition of operating double :kers.

unnions

Edbro rams — which can inde up to eight extensions — Isist of a number of steel les telescoped inside each er with replaceable fabric Is supported by retainer ;hes fitted to each tube. Inporated in each bush at the id of every tube are wiper Is to prevent the ingress of tign matter. The top of the ram terminate in a ball-and-socket joint to alloy for universal movement. At thi bottom, a trunnion arm i welded to the outer diameter o the base tube which in turn i located in semi-circular U shaped slots in a box-sectior cradle unit. A securing plate then bolted over the slots t( secure the trunnion to th( cradle.

The cradle unit incorporate! two trunnion arms which ar( positioned on the outside of the cradle at 90 to the ram trun nions. On assembly of the complete cradle inside a chassi. subframe, the trunnions enable the ram unit to pivot in three directions.

Subframe

As the total load is being thrust through the centre of the chassis, ie at its weakest point, a reinforcing subframe is essential with a three-way tipper. This subframe embodies booms for the side and end tipping pivots and an underfloor tank containing the hydraulic oil.

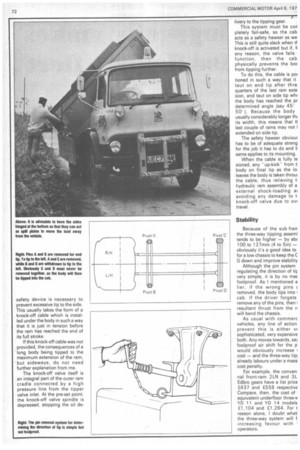

The corner pedestals for fixing to the body incorporate removable locking pins. Removal of these pins in the correct pattern determines the direction of tip as shown in the diagram). Obviously pins C and D must never be removed together, otherwise the body will be tipped straight into the back of the cab!

Edbro's latest type of threeway tipper, the YD series, comes complete with integral pto and multi-cylinder hydraulic pump. There are six basic sizes with lifting capacities ranging from five to 20 tons. The operating pressure for the ram is in the region of 170 bar (2,500psi).

Safety

Because a three-way tipper tips further to the rear than it does to the sides, some form of safety device is necessary to prevent excessive tip to the side. This usually takes the form of a knock-off cable which is installed under the body in such a way that it is just in tension before the ram has reached the end of its full stroke.

If this knock-off cable was not provided, the consequences of a long body being tipped to the maximum extension of the ram, but sideways, do not need further explanation from me.

The knock-off valve itself is an integral part of the outer ram cradle connected by a high pressure line from the tipper valve inlet. At the pre-set point, the knock-off valve spindle is depressed, stopping the oil de livery to the tipping gear.

This system must be con pletely fail-safe, so the cab acts as a safety hawser as we This is still quite slack when tt knock-off is activated but if, f any reason, the valve fails function, then the cab physically prevents the boc from tipping further.

To do this, the cable is poi toned in such a way that it taut on end tip after thre quarters of the last ram exte sion, and taut on side tip wh( the body has reached the pr determined angle (say 45' 50-). Because the body usually considerably longer thi its width, this means that tl last couple of rams may not I extended on side tip.

The safety hawser obviout has to be of adequate streng for the job it has to do and tl same applies to its mounting.

When the cable is fully te sioned, any "up-kick" from t body on final tip as the la leaves the body is taken throu■ the cable, thus relieving t hydraulic ram assembly of a external shock-loading ai avoiding any damage to t knock-off valve due to ovi travel.

Stability

Because of the sub fran the three-way tipping asseml tends to be higher — by ab( 100 to 127mm to 5in) — obviously it's a good idea to for a low chassis to keep the C G down and improve stability Although the pin system regulating the direction of tir very simple, it is by no meE foolproof. As I mentioned e lier, if the wrong pins removed, the body tips into 1 cab. If the driver forgets remove any of the pins, then1 resultant thrust from the ri will bend the chassis.

As usual with commerc vehicles, any line of action prevent this is either v( sophisticated, very expensive both. Any moves towards, sat foolproof air shift for the p would obviously increase I cost — and the three-way tip! already labours under a mass cost penalty.

For example, the conven. nal front-ram 2LN and 3L Edbro gears have a list price

£437 and £558 respectivE Compare, then, the cost of equivalent underfloor three-v YD 11 and YD 14 models £1,104 and £1,264. For t reason alone, I doubt whet the three-way system will f increasing favour with operators. 1E CAPABILITY to move 3terials swiftly to get maxiirn utilisation of high capital st equipment is of paramount portance when a transport mager has to operate a fleet of hides during periods of mornic unrest.

For tipper and skip operators, ire is a vast range of standard uipment available, but with a le ingenuity it is possible to Ike the fleet more adaptable, increasing the range of work it can be tackled.

Several tipper operators have ind that productivity can be reased by fitting grab-loaders that one man can move soil ickly at road works and ilding sites, particularly ere space is limited. Doing job with a gang of men is iensive and where skips are id on road works, they tend to ;ome semi-permanent on the foughfare, which causes a at deal of resentment from idents and shop keepers, as I as dislocating traffic flow. Three-way tipper bodies are :oming increasingly popular h local authorities, particuwhen offloading materials to the roadside. This usually ninates stopping the cornte traffic flow while the icle is moved into position I the load discharged from rear in the more usual man Nhen a vehicle is purchased a specific contract the body ign and construction can be .ched to the job and type of i, provided that there is an rnative use at the end of the tract period.

)therwise this means dispoof the complete vehicle or Ddying the chassis, which affect profitability of the tract.