Long-life bogie rides on rubber

Page 48

Page 49

Page 50

If you've noticed an error in this article please click here to report it so we can fix it.

Tipper operators should turn to a new leaf-rubber's all the rage Fodens for prolonging active tipper life.

Join Steve Gray in the fight against premature failure....

THE BANE of every tipper or cement mixer operator must without doubt be the maintenance of his vehicles. Working in harsh on/off road conditions, day in, day out they are subject to more abuse than virtually any other type of vehicle. Abrasive sand, cement dust and other foreign bodies wreak havoc with all moving parts of the truck, drastically reducing the effective life of many components.

One of the most susceptible parts of the running gear, on both six and eight-wheelers, is the rear bogie. Not only is it, too, subjected to ingress of abrasive material, but its very construction lends itself to wear.

On a typical four-spring bogie, there are numerous moving parts which are constantly subject to wear. Spring anchors, shackle-pins and bushes and locating bars all move and thus are liable to accelerated premature failure. In addition, the springs themselves wear as the leaves move and in winter, when salt is on the roads, an electrolytic action can occur between the spring leaves, again causing failure.

Finally, of course, there is the ever-present possibility of broken spring leaves as the vehicle bounces unladen over rough terrain. In pure financial terms, the cost of replacing these components is high, but worse still is the inevitable dovl time and loss of use.

Now, in a bold move, Fade have standardised on rubL suspension for their Haulmas' six-wheeler and offer rubh suspension as an option on t eight-wheeler Haulmast( These vehicles are shown for t first time this year at the Fn. Tipper Convention, Harrogate To find out why Fodens ha decided on rubber, and to c. the feel of the new suspensior visited the company's Elwoi works at Sandbach, talked the design engineers respor ible and took a prototype s wheeler round Fodens nom road-test circuit and test track

Basically Fodens use two c ferent types of rubber susp( sion for the six and eigl wheelers — the FF20 on the and the FR20 on the eight. T FF20 is Fodens' own design, while the FR20 is a development of the Rydewell system manufactured under licence. As the forces involved on the eight-wheeler are greater, Rydewell was chosen as an established design which needed little development.

However, its heavier weight, which was acceptable on an eight-legger would have detracted from the payload of the six. For this reason Foden developed the FF20 using Dunlop Metalastik units. The design is based around that of Dunlop, which is protected by prior use and is not patentable. The rubber units are supplied by Dunlop and all the rest is of Foden manufacture .

But by far the best news is that Fodens' engineers have succeeded in keeping the weight of the bogie down. Using rubber suspension units invariably means an increase in

weight over conventional tot spring or two-spring bogies. Fodens case only 1 3kg (1/4cvi has been added en the unladi weight of the 6x4, compared one equipped with a taper-le four-spring bogie.

This is no small achiev ment, as it must be remem ered that conventional multi-le springs weigh more and ti rubber set-up is virtually no reactive.

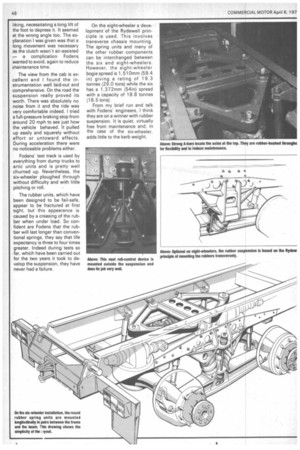

(talked to John Gerrard, tl designer who worked on tl FF20, about its design featur and operation. First of all, Jot told me, the rubber units, whii are of round section, a arranged in pairs longitudinal between the frame arid the su pension beam centre. The su pension beams are attached the axles and the axles a located by two A-bars at the tc of the chassis.

Rubber bushes are us( throughout to obviate maim nance. No lower torque rods a necessary. To reduce roll, a ne roll control device is fitted, co sisting simply of twin rubbe linked by a rod and mounted the outside of the bogie. rubber doesn't have any in-bu damping, shock absorbers a fitted to both axles and a loi sensing device is standard.

The rubber suspension bog is virtually non-reactive braking and acceleration force John Gerrard told me, and bog hop has been eliminated. A other distinct advantage is th the rubber bushing of the A-ba provides a certain flexibilit which in turn gives irnprov( tyre life because of less scru From a comfort viewpoint, tl bogie is silent in its operati( with none of the clankin, rattles and squeaks associato with spring bogies.

I took a six-wheeler chas; on a run around Fodens te track and on the road route ti factory normally use.

It was not fitted with a boc but was loaded with test weigh to its maximum 24.4 tonn, (24 tons) gvvv. It was the fir time I had had an opportunity drive a Foden with the ne grp /steel composite cab. I mu say that I was very favourab impressed with both its interi noise levels and general level comfort.

Fodens stressed that this w a pre-production prototype ar a few of the minor criticisms raised about it — such as a d gree of flexibility in the tops the doors — had been correct( for production models.

However, I found the clut( pedal a little too high for n

liking, necessitating a long lift of the foot to depress it. It seemed at the wrong angle too. The explanation I was given was that a long movement was necessary as the clutch wasn't air-assisted a complication Fodens wanted to avoid, again to reduce maintenance time.

The view from the cab is excellent and I found the instrumentation well laid-out and comprehensive. On the road the suspension really proved its worth. There was absolutely no noise from it and the ride was very comfortable indeed. I tried a full-pressure braking stop from around 20 mph to see just how the vehicle behaved. It pulled up easily and squarely without effort or untoward effects. During acceleration there were no noticeable problems either.

Fodens' test track is used by everything from dump trucks to artic units and is pretty well churned up. Nevertheless, the six-wheeler ploughed through without difficulty and with little pitching or roll.

The rubber units, which have been designed to be fail-safe, appear to be fractured at first sight, but this appearance is caused by a creasing of the rubber when under load. So confident are Fodens that the rubber will last longer than conventional springs, they say that life expectancy is three to four times greater. Indeed during tests so .far, which have been carried out for the two years it took to develop the suspension, they have never had a failure. On the eight-wheeler a development of the Rydewell principle is used. This involves transverse chassis mounting. The spring units and many of the other rubber components can be interchanged between the six and eight-wheelers. However, the eight-wheeler bogie spread is 1,510mm (59.4 in) giving a rating of 19.3 tonnes (29.0 tons) while the six has a 1,372mm (54in) spread with a capacity of 18.8 tonnes (18.5 tons).

From my brief run and talk with Fodens' engineers, I think they are on a winner with rubber suspension. It is quiet, virtually free from maintenance and, in the case of the six-wheeler, adds little to the kerb weight.