THE SAFE LOADING OF VEHICLES

Page 54

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

LOAD SAFETY is not simply a matter of ropes. chains and twistlocks. The first essentials are a sufficiently skilful driver and a suitable vehicle for the load. An experienced, level-headed driver will get a tricky load of flaxboard over steep and winding roads without mishap while a careless or clumsy man may contrive to shoot the most carefully packed load at the first roundabout.

One still sees 30ft containers sitting on loose dunnage on a platform trailer (though much less often these days) and, less dramatically but nevertheless bad practice, one sees 20ft lengths of wood or metal habitually carried on a 14f1 load bed.

When driver and vehicle are right for the load, it is still necessary to see that the load platform is clean and free from grease; with certain types of cargo. especially flat sheets, it is also important to have a dry platform.

The lavv's demands

For many years the law has required that loads carried by motor vehicles or trailers shall at all times be secured or positioned in such a way that danger is not likely to be caused to any person. (The full legal obligation is set out in Section 90 of The Motor Vehicles (Construction and Use) Regulations 1973.) However, the interpretation of what was, or was not, a safe practice remained largely a matter of opinion and circumstance until the publication in October 1972 of the Department of the Environment's Code of Practice: Safety of loads on vehicles, This Code is not in itself a legal document (and does not carry even the weight of the Highway Code) but its recommendations are likely to be taken very seriously by courts asked to adjudicate on cases of alleged dangerous loading.

The Code (which costs 30p net from HMSO or booksellers) has been compiled with the aid of engineering and transport trade associations, the police, the transport trade unions and government bodies. Its object is to provide operators, drivers and loading staff with guidance on the basic safety principles which must be followed, and also some particular precautions which need to be observed.

Sufficient restraint

The two most common causes of loads shifting or falling are the braking or swerving of the vehicle. The Code recommends that load restraint with a strength at least equal to the static weight of the load is necessary to prevent it moving forward under heavy braking. Sideways or rearward movement needs to be prevented by restraining forces at least equal to half the weight of the total load.

To visualize what this means in practice, a 10-ton load needs to be held back by 10 lashings of at least 1 ton capacity or five of 2 tons capacity — or the equivalent.

The front of a load should be abutted against the headboard or against a baulk fitted transversely across the platform and firmly secured to the chassis frame — not simply to the body. The load should, where possible, be spread to keep the centre of gravity low. Large and heavy items should obviously be at the bottom, and heavy, solid items should be positioned ahead of light, crushable ones.

It is dangerous to position loads at a distance behind the headboard of a platform vehicle, unless they are firmly secured; once a load starts to move the "battering ram" effect increases rapidly with the distance over which it moves. A headboard with 5-ton restraining ability will not stop a 5-ton load which has slid 6ft under heavy braking before hitting it.

The Code recommends that traditional rope hooks should not be regarded as lashing points for load securing. It suggests that load anchorage points with an SWL of 0.5, 1.0 or 2.0 tons should be fitted to the chassis members (as shown in a diagram).

On platform vehicles, headboards should be capable of withstanding a horizontal force, uniformly distributed over the vertical area, equal to half the payload capacity of the truck.

Rope caution The selection of the means for securing a load on a platform will depend to a large extent on the type and construction of the load to be carried. Clamps, special bolts, steel wire rope, chains, webbing straps, cordage and, when used with van bodies, shoring bars, are all suitable devices. Cordage (rope) however, whether made from natural or synthetic fibre, should be used with care as its strength cannot readily be assessed and it can be seriously weakened by age, wear or incorrect use.

The Code gives useful guidance on the selection of lashing devices — including purpose-made webbing, harnesses and nets.

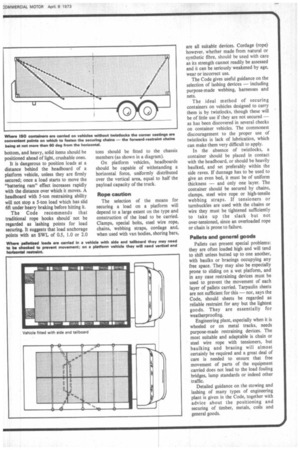

The ideal method of securing containers on vehicles designed to carry them is by twistlocks, though these will be of little use if they are not secured — as has been discovered in several checks on container vehicles. The commonest discouragement to the proper use of twistlocks is lack of lubrication, which can make them very difficult to apply.

In the absence of twistlocks, a container should be placed in contact with the headboard, or should be heavily baulked, and set preferably within the side raves. If dunnage has to be used to give an even bed, it must be of uniform thickness — and only one layer. The container should be secured by chains, clamps, steel wire rope or high-tensile webbing straps. If tensioners or turnbuckles are used with the chains or wire they must be tightened sufficiently to take up the slack but not over-tensioned, since an overloaded rope or chain is prone to failure.

Pallets and general goods Pallets can present special problems: they are often loaded high and will tend to shift unless butted up to one another, with baulks or bracings occupying any free space. They may also be especially prone to sliding on a wet platform, and in any case restraining devices must be used to prevent the movement of each layer of pallets carried. Tarpaulin sheets are not sufficient for this — nor, says the Code, should sheets be regarded as reliable restraint for any but the lightest goods. They are essentially for weatherproofing.

Engineering plant, especially when it is wheeled or on metal tracks, needs purpose-made restraining devices. The most suitable and adaptable is chain or steel wire rope with tensioners, but baulking and bracing will almost certainly be required and a great deal of care is needed to ensure that free movement of parts of the equipment carried does not lead to the load fouling bridges, lamp standards or indeed other traffic.

Detailed guidance on the stowing and lashing of many types of engineering plant is given in the Code, together with advice about the positioning and securing of timber, metals, coils and general goods.