Road Transport for Railway Vehicles

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

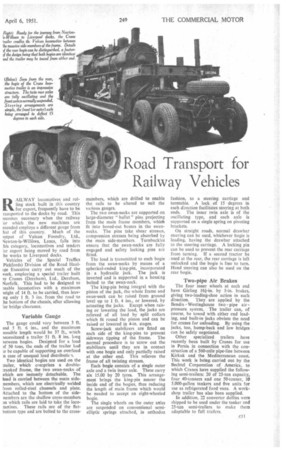

RAILWAY locomotives and rolling stock built in this country for export, frequently have to be ransported to the docks by road. This iecomes necessary when the railway or which _ the new machines are ntended employs a different gauge from

hat of this country. Much of the iutput of Vulcan Foundry, Ltd., Newton-le-Willows, Lanes, falls into his category, locomotives and tenders or export being moved by road from he works to Liverpool docks.

Vehicles of the Special Traffics Pickfords) Division of the Road Haultge Executive carry out much of the vork, employing a special trailer built ry Cranes (Dereham), Ltd., Dereham, Norfolk. This had to be designed to inable locomotives with a maximum teight of 14 ft. to be carried, thus leavng only 1 ft. 3 ins, from the road -to he bottom of the chassis, after allowing 'or bridge clearance.

Variable Gauge The gauge could vary between 3 ft. Ind 5 ft. 6 ins., and the maximum )ossible length would be 37 ft., wnich iecessitated a trailer 51 ft. 8 ins. long Jetween bogies. Designed for a load )f 50 tons, the ends of the trailer had :o be capable of supporting an overload n case of unequal load distributicl. Two identical bogies are used on the railer, which comprises a double:ranked frame, the two swan-necks of which are instantly detachable. The load is carried between the main sidemembers, which are electrically welded from rolled-steel channels and plate. Attached to the bottom of the sidenembers are the shallow cross-members 3n which rails are laid to take the locomotives. These rails are of the fiatbottom type and are bolted to the cross members, which are drilled to enable the rails to be altered to suit the various gauges.

The two swan-necks are supported on large-diameter " bullet " pins projecting from the main frame members, which fit into bored-out bosses in the swannecks. The pins take shear stresses, compression stresses being absorbed by the main side-members. Turnbuckles ensure that the swan-necks are fully engaged and safety locking pins are fitted.

The load is transmitted to each bogie from the swan-necks by means of a spherical-ended king-pin, incorporated in a hydraulic jack. The jack is inverted and is supported in a housing bolted to the swan-neck.

The king-pin being integral with the piston of the jack, the whole frame and swan-neck can be raised from ground level up to 1 ft. 4 ins., or lowered, by actuating the jacks. Except when raising or lowering the load, the jacks are relieved of all load by split collars which fit round the piston and can be raised or lowered in 4-in. stages.

Screw-jack stabilizers are fitted on each side of the king-pins to prevent sideways tipping of the frame. The normal procedure is to screw out the stabilizers until they are in contact with one bogie and only partially raised at the other end. This relieves the frame of all twisting stresses.

Each bogie consists of a single outer axle and a twin inner axle. These carry six 15.00 by 20 tyres. This arrangement brings the king-pin nearer the inside end of the bogies, thus reducing the length of main frame which would be needed to accept an eight-wheeled bogie.

The single wheels on the outer ales are suspended on conventional semielliptic springs attached, in orthodox fashion, to a steering carriage and turntable. A lock of 15 degrees in each directionfacilitates steering at both ends. The inner twin axle is of the oscillating type, and each axle is supported on a single spring on pivoting brackets.

On straight roads, normal drawbar steering can be used, whichever bogie is leading, having the drawbar attached to the steering carriage. A locking pin can be used to prevent the rear carriage from turning. If a second tractor be • used at the rear, the rear carriage is left unlocked and the bogie is free to turn. Hand steering can also be used on the rear bogie.

Two-pipe Air Brakes

The four inner wheels at each end have Girling 16+-in, by 5-in, brakes, giving two-leading-shoe action in each direction. They are applied by the Bendix Westinghouse two pipe air pressure system. The trailer can, of course, be towed with either end leading, and built-in jacks obviate the need for cranes for unloading. By using the jacks, too, bump-back and low bridges can be safely negotiated.

Other specialized trailers have recently been built by Cranes for use in Persia in connection with the construction of a 560-mile pipe-line between Kirkuk and the Mediterranean coast. This work is being carried out by the Bechtel Corporation of America, to which Cranes have supplied the following semi-trailers: 20 of 25-ton capacity, four 40-tonners and one 50-tonner, 10 5,000-gallon tankers and five units for use as refrigerated food vans. A workshop trailer has also been supplied.

In addition, 22 converter dollies were shipped to be used under the tanker and 25-ton semi-trailers to make them adaptable to full trailers.