ENGINES: PAST, PRESENT AND FUTURE.

Page 20

Page 21

Page 22

If you've noticed an error in this article please click here to report it so we can fix it.

An Epitome of the Chief Improvements. Why Lighter Engines Produce More Power. The Possibilities of the Unit with Horizontally Opposed Cylinders.

THAT a difference is presented by the exterior of the present-day commercial vehicle when compared with that of the types in use at the time of the inauguration of The Commercial Motor in 1905. Then steam wagons with unsprung wheels, no tyres and an exposed position for the driver were at least as popular as, if not more so than, the rather elementary types of vehicle driven by internal-combustion engines.

All the old types of vehicle were, without exception, equipped with large, slow-speed engines, some with two cylinders, others with four, but this latter figure represented the maximum in general use, whilst a revolution speed of 1,200 was considered quite high. Efforts at improvement were characterized more by an attempt on the part of designers to obtain more power per stroke rather than by crowding more strokes into a given time, thereby increasing revolution speed.

To increase the power of one of the old types of engine at low speeds was exceedingly difficult, as practically all alterations had to be made to the der head, and it was not then appreciated that the exact shape of the combustion chamber and the disposition of the valves were of such vital importance as is now known to be the ease. Compression ratios as low as 3.5 to 1 were the general order of the day, and if this amount were increased detonation, or what is more commonly known as knocking, commenced. This, then, proved to be a difficulty which required years of research to rectify, but the moment the right lines were struck the field of development enlarged immediately.

Briefly to summarize these possibilities, it might be mentioned that gas velocity, compression ratio, the shape and size of the combustion chamber and the number and disposition of the cylinders are all interconnected in the sekreh for thermal efficiency, and if any one point be neglected the effect upon the engine is one of retrogression rather than progress. So far only thermal efficiency has been considered, but mechanical efficiency also plays a very large part in the performance of an internal-combustion engine, not cpaly from the point 236 of view of actual power output, but also from considerations such as silence, sweetness during running, acceleration, etc.

To return for a moment to the consideration of the old type of engine in which, hitherto, revolution speeds were not sought after to any marked extent, it is perhaps as well to trace the cause for it. It is to be found rather in the mechanical side than in the thermal, the limiting factors being excessive vibration, resulting from very heavy reciprocating parts. In the first place the engines had of necessity to be of large dimensions (both in bore and stroke), reeniting in bulky and, consequently, heavy pistons, connecting rods and valves, whilst the revolving masses, such as the crankshaft, • big-ends of the connecting rods, flywheel, etc., were of such huge dimensions that rapid acceleration was also affected.

By the introduction of aluminium alloys suitable for piston construction a new field of development was *opened up, which, of course, immediately made permissible an increase in revolution speeds, even with the old large-bore type of engine. This increase in speed then threw into relief the necessity for a fast-burning mixture to cope with the increased expansion rates, so that efforts were made to incorporate in the design of the combustion chamber a sufficiently smooth and compact surface to encourage turbulence—probably one of the greatest factors in the functioning of the internalcombustion engine.

The progress made in engine design since the war has been much greater and farther reaching in its effects than that during the preceding eight years, as the modern vehicle is, without doubt, a most reliable, comfortable and useful means of transport and will run for long periods without requiring the attentions of the repair shop. In some of the later engines brakehorse-powers in excess of 70 have been obtained at 2,000 r.p.m. for a piston-swept volume of under six litres, whilst 80 b.h.p. has been obtained at a similar revolution speed from six and a half litres. Thesc figures compare very favourably indeed with some oi the older types made even only a few years ago, it which the maximum revolution speed was in the ordei of 1,400 and the maximum power round about 40 b.h.p. for similar capacities. Petrol consumption, too, has,

by virtue of the increased thermal efficiency of the unit, been improved out of all recognition. In the example , just quoted the most " efficient" engine speed is obtained at about 1,000 r.p.m., where the consumption per b.h.p.-hour is only .65 pint.

The weight of the modern engine as a whole for a

given b.h.p. output is, of course, . considerably lower than in the older types, thereby allowing a lighter chassis generally to be adopted, so that the advantage of a reduction in engine size gives twofold benefits. Howwill this quality affect future developmlent? Will further reductions in size be permissible for a given output, and, if so, What effect will that produce on the design of the chassis? To answer these question it will, perhaps, be an advantage to refer to the development of the racing car engine. Here the great tendency is towards a continual reduction in engine size, yet the power output is steadily increasing, despite the reduction. At the same tiny the number of cylinders per engine is being greatly increased to make higher piston speeds attainable without overloading the bearings of the engine by excessive inertia stresses.

It is well known that the weight of a component such as a piston varies roughly as the cube of the diameter, so it can easily be -seen that, as this is increased, the weight rises very rapidly', and, of course, this rule acts equally when applied conversely.

Inertia is dependent upon weight and velocity7. it is obvious, therefore, that for a given total piston-swept volume a large number of pistons can operate at a higher speed than a small number, so that the multicylinder engine should not only run much more smoothly, but should also provide a considerably increased power output. Various limitations in construction become apparent when attempts are made in this direction, and whilst it is well known that the design of the internal-combustion engine is a compromise, several factors, other than those already enumerated, enter into the question and alter it somewhat. For instance, with many cylinders the housing of the bigends of the connecting rods on the crankshaft, with bearings of sufficient size to allow them to be run for prolonged periods without wear, calls for great care in the layout and often proves to be the factor. determining the total length of the engine.

Several of the two-litre engines in the 1024-1925 Grand Prix racing cars have developed 150-200 b.h.p. and have proved themselves capable of running practically all out for hundreds of miles at a stretch, demonstrating thereby that, although they run at colossal revolution speeds, it is only a matter of time before reliability at those speeds can be obtained, troubles being eliminated by degrees during the course of time.

Whilst it is not intended to convey the impression that engines such as these are suitable for commercial vehicles, a modified edition will, without doubt, eventtially be developed in a few years' time, and two-litre engines developing 100 b.h.p. (only half the power already attained by a racing engine of the same size) should be commercially practicable, and would greatly improve the performance and utility of the vehicle in Which such engines were installed.

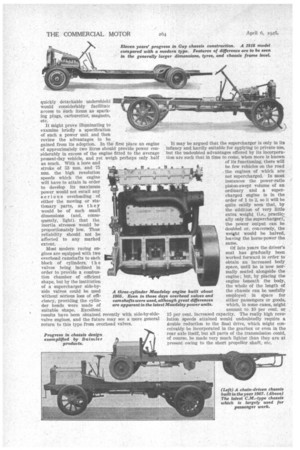

The advantages of dynamic balance of the reciprocating parts are too well known tu need recapitulation, and it is rather extraordinary that no great tendency has been shown towards the adoption of the horizontally opposed layout for the cylinders. With this scheme the pistons are perfectly balanced, both between themselves and on the crankshaft, which enables a very light construction for the engine as a whole to be adopted; further, it is possible so to construct the unit that its vertical dimension is very small.

• If a horizontally opposed engine were adopted it would he possible to dispense with the conventional bonnet as at present almost universally used and position the engine midway along the chassis. The only serious disadvantage of this layout would be inaccessibility, but engines nowadays are becoming so reliable that the amount of attention required by them is decreasing steadily but surely, and it can almost be said that roadside repairs or adjustments are now nonextant. Arrangements could be made whereby a quickly detachable undershield would considerably facilitate access to such items as sparking plugs, carburetter, magneto, etc.

It might prove illuminating to examine briefly a specification of such a power unit and then review the advantages to be gained from its adoption. In the first place an engine of approximately two litres should provide power considerably in excess of the engine fitted to the average present-clay vehicle, and yet weigh perhaps only half as much. With a bore and stroke of 53 mm. and 75 ram. the high revolution speeds which the engine will have to attain in order to develop its maximum power would not entail any serious overloading of either the moving or stationary parts, as they would be of such small dimensions (and, consequently, light) that the inertia stresses would be proportionately low. Thus reliability should not be affected to any marked extent.

Most modern racing engines are equipped with two overhead camshafts to each block of cylinders, t h e valves being inclined in order to provide a combustion chamber of efficient shape, but by the institution of a supercharger side-byside valves could be used without serious loss of efficiency, providing the cylinder heads were made of suitable shape. Excellent results have been obtained recently with side-by-sidevalve engines, and the future may see a more general return to this type from overhead valves. , It may be argued that the supercharger is only in its Infancy and hardly suitable for applying to private use, but the undoubted advantages offered by its incorporation are such that in time to come, when more is known of its functioning, there will be few vehicles on the road the engines of which are not supercharged. In most instances the power-ratio piston-swept volume of an ordinary and a supercharged engine is in the order of 1 to 2, so it will be quite edsily seen that, by the addition of very little extra weight (i.e., practically only the supercharger); the power output can be doubled or, conversely, the weight would be halved, leaving the horse-power the same.

Of late years the driver's seat has gradually been worked forward in order to obtain an increased body space, until he is now normally seated alongside the engine; but, by placing the engine beneath the body, the whole of the length of the chassis can be usefully employed• in space for either passengers or goods, which, in some cases, might amount to 10 per cent. or 15 per cent, increased capacity. The really high revolution speeds attained would undoubtedly require a double reduction to the final drive, which might conceivably be incorporated in the gearbox or even in the rear axle itself, but all parts of the transmission could, of course, be made very much lighter than they are at present owing to the short propeller shaft, etc.