ANOTHER LARGE-CAf Y BRITISH CHASSIS

Page 16

Page 17

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

Exclusive Details of the •New 5-6-ton Dt Reinforced Fro Lich has a Highly Efficient Power Unit, Worm Drive.

A IPTER a close inspection and test of the latest pro..ti-duct from the famous Dennis works, at Guildford, we are convinced that this 5-6-ton model will prove a most successful one in the hands of Users. The capabilities of its highly efficient engine are ample, and with 'a gross weight of 10 tons, of which 6 tons was pay load, one of these vehicles has run over average give-and-take roads at eight miles to the gallon, thus giving the very satisfactory figure of 80 ton-miles to the gallon. At a petrol consumption of .58 pt. per b.h.p. 47 b.h.p. can be obtained, whilst a maximum of 70 b.h.p.

can be developed. • The chassis, although of ample strength, is, for its lead capacity, comparatively light, weighing only 3 tons 9 cwt., the main dimensions being : Overall length, 21 ft. 6 ins. ; wheelbase, 14 ft. 2f ; track, 5 ft. 6 ins. ; frame height (laden), 3 ft. # ; clearance, 10f ins.; dash to end of frame, 16 ft. 6# ; turning cintle, 46 ft. 6 ins., the price being £840, or, with a wheelbase of 15 ft. 6 ins., £860. These prices include the following equipment :—Front mudguards, 6-volt .dynamo lighting set, comprising two headlamps, tail lamp and two side lamps (which are provided with oil -burners and can be used as oil lamps immediately in emergency) ; tool kit, lifting jack and electric horn.

We will now describe the chassis in detail. Dealing first with the frame, the side-members are straight but tapered up to the dumb-irons,. at the points of attachment of which the channel is reinforced by channel liners. A narrow reinforcing channel also stretches under each side-member from about the middle of the gearbox to the forward rear-spring bracket, the lower flange of each side-member being bolted at a large number of points to the upper flange of the additional member, thus transferring part of the tensional stresses on It to the lower flange of the reinforcement. There are five channel cross-members with integral end gussets.

Somewhat unusual construction is employed for the channel steel sub-frame which carries the gearbox and the bracket for the foot-brake bell-crank. This subframe is suspended from the rear cross-bearer of the engine, whilst the front end of the power unit is carried in a spherical bearing.

It is notable that the gearbox is suspended by eight bolts, so that it can be dropped clear without interfer

lug with the body. Extending from the engine to the back a the gearbox is the undershield of non-rusting sheet steel, which is supported in position by spring clips hooked into the channels of the sub-frame.

In the new chassis all the leading features which have proved so successful in former Dennis models have been embodied, together with a number of improvements. There is the excellent torque-tube-ball housing, which is mounted in rubber trunnions carried in brackets bolted inside the frame members, whilst one cross-member is slightly arched to clear the torque tube.

There are very stout spring brackets at the rear, each forming a rectangle supporting both ends offthe spring pin. The springs themselves are of special chrome steel, long, and with the second leaf of each supporting the eyes. Neat helicoidaI auxiliary springs are mounted on brackets bolted to the side-members, their ends making contact with the spring plates when the vehicle is loaded. This permits the provision of springs flexible enough to give good riding when the vehicle is light or is only partly loaded.

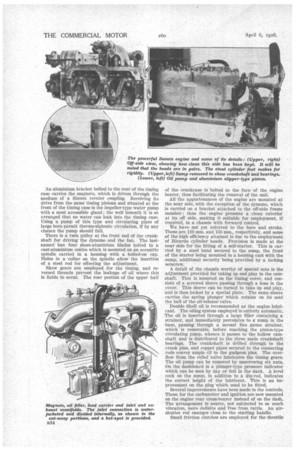

The power unit has four cylinders cast en bloc with detachable heads in pairs, each held by 12 brass cap nuts. There is also a brass outlet branch leading to the radiator. All the valves are at the near side, the tappets being protected by large aluminium covers with Langite cork gaskets, and each held by one knurled nut; lugs are provided for lifting purposes. The tappets and valves are lubricated by oil mist from the crankcase, communication being by drilled holes.

A feature of the design is the unusual thickness of the flange at the feet of the cylinders. This ensures extreme rigidity. Incidentally, castle nuts instead of plain nuts are employed for holding down the cylinders.

The carburetting arrangements are somewhat un usual. The instrument is a Claudel-Hobson with a water-heated inlet pipe divided by a central partition. This is bolted to an aluminium manifold similarly divided and also bolted to a flange on the exhaust manifold, which provides a hot:spot. The arrangement is such that an even flow of mixture to each cylinder is obtained. In many designs this is not possible, and one cylinder may receiVe a bigger charge than another, so that the explosions are not even.

An aluminium bracket bolted to the rear of the timing case carries the magneto, which is driven through the medium of a Simms vernier coupling. Receiving its drive from the same timing pinions and situated at the front of the timing case is the impeller-type water pump with a most accessible gland ; the well beneath it is so arranged that no water can leak into the timing case. Using a pump of this type and circulating pipes of large bore permit thermo-siphonic circulation, if by any chance the 'pump should fail.

There is a twin pulley at the front end of the crankshaft for driving the dynamo and the fan. The lastnamed has four sheet-aluminium blades bolted to a cast-aluminium centre which is mounted on in eccentric spindle carried in a housing with a bolted-on cap. Holes in a 'collar on the spindle allow the insertion of a steel rod for effecting the adjustment.

Skew gears are employed for the timing, and reversed threads prevent the leakage of oil where this is liable to occur. The rear portion of the upper half of the crankcase is bolted to the face of the engine hearer, thus facilitating the removal of the unit.

All the appurtenances of the engine are mounted at the near side, with the exception of the dynamo, which is carried on a bracket attached to the off-side frame member ; thus the engine presents a clean exterior at its off side, making it suitable for employment, if required, in a chassis with forward control.

We have not yet referred to the bore and stroke. These are 110 mm. and 150 mm., respectively, and some of the high efficiency attained iS due to the employment of Ricardo cylinder heads. Provision is made at the near side for the fitting of a self-starter. This is carried by a steel band secured to the sump, the front of the starter being mounted in a housing east with the sump, additional security being provided by a locking setscrew.

A detail of the chassis worthy of special note is the adjustment provided for taking up end play in the camshaft. This is mounted on the timing cover, and consists of a screwed sleeve passing through a boss in the cover. This sleeve can be turned to take up end play, and is then locked by a special plate. The same sleeve carries the spring plunger which retains on its seat the ball of the oil-release valve.

Double Shell oil is recommended as the engine lubricant. The oiling system employed is entirely automatic. The oil is inserted through a large filler containing a strainer, and immediately percolates to a sump in the base, passing_ through a second fine gauze strainer, which is removable, before reaching the pinion-type circulating pump, whence it passes to the hollow camshaft and is distributed to the three main crankshaft hearings. The crankshaft is drilled through to the crank pins, and copper pipes secured to the connecting rods convey ample ell to the gudgeon pins. The overflow from the relief valve lubricates the timing gears. The oil pump can be removed by unscrewing six nuts, On the dashboard is a plunger-type pressure indicator which can be seen by day .or felt in the dark. A level cock on the sump, in addition to a dip-rod, indicates the correct height of the lubricant. This is an improvement on the plug which used to be fitted.

Several improvements have been made in the Controls. Those for the carburetter and ignition are now mounted on the engine rear cross-bearer instead of on the dash. The arrangement is neater, not subjected to so much vibration, more definite and free from rattle. An airshutter rod emerges close to the starting handle.

Small friction clutches are employed for the throttle and ignition levers on the steering column. Incidentally, the carburetter is of the diffuser type with an extra power jet which comes into operation at about three-quarter throttle; the effect of this is -very noticeable, and gives a useful reserve of power.

From the engine the drive is taken through a fabricfaced external cone clutch with three external coil compression springs, each of which can be easily adjusted by a nut and lock-nut, a split-pin forming an additional safeguard. At each side is a Ferodo-faced sprung clutch stop carried ona square spindle passing through a bracket bolted to the sub-frame. Direct clutch withdrawal by two arms connected between two levers on the pedal shaft and a floating collar on the clutch shaft, is employed.

Two triple flexible-fabric joints connect the clutch t.1 gearbox. Fotir speeds are provided, and the box Las a large cover giving the maximum opening, and a smaller cover for the introduction Oflubricant. A level cock allows the oil to be one inch up the largest gearwheel. There are two selector rods with spring-plunger hacks.

At the back of the gearbox is the powerful transmission brake, which is equipped with shoe carriers. having centrally fulcrumed shoes of cast-iron, each balanced by a setscrew. Beyond this is an open propeller shaft with two enclosed universal joints of the all-metal type, the rear one being carried in the spherical end of the torque tube. The final drive is by overhead worm in a pot-type axle casing with bolted-on ends forming the spring carriers, tubes being passed -through these into the centre casting.

A clip passes round each spring and is bolted to the upper spring plate, which, in turn, is bolted to the spring seat. This .centre clip fits into a slot in the seat and thus prevents the spring from moving out of posh ion.

Open brake drums are bolted to the Y-spoked caststeel wheels, and each shoe is located on its fulcrum pin by a setscrew locking into a groove in the pin, this facilitating removal. The brake shaft is carried in spherical bearings and the rods have self-locking adjusters. The shoes are of the all-metal type.

All fork and pin joints liable to cause vibration are fitted with Thackray spring washers, whilst Tecalemit lubricators are provided throughout, except in the ease of the torque-tube ball, which is lubricated from the side of the chassis from an oil cup located on the side member. The round petrol tank, which is of large capacity, is carried under the driver's seat.

Protection is afforded the drive r, and the appearance of the chassis improved by the provision of a steel scuttle dash with neat welded corner pieces.

Worm-and-sector steering gear with ball joints for the link and track rods are provided.

The engine bonnet is given a gradual taper from the dash to the radiator both as regards the top and the sides, and this greatly improves the appearance.

A point in the design of the engine is that an easily removable cover is fitted above the timing ease; this can quickly be lifted and a governor fitted if required. Dunlop tyres—singles at the front and twins at the rear—are fitted as standard, the dimensions being 130 mm. for 850 mm. by 1,000 mm. at the front and 140 mm. for 850 mm. by 1,016 rem. at the rear.

With this chassis the vehicle can accelerate to give a road speed of 20 m.p.h., whilst gradients of 1 in 6 can be climbed with full load.

The new chassis is a worthy addition to the range of Britishbuilt vehicles which is available for heavyloads, and our tests ofits capabilities prove that it is simple to control and provides ample power to meet all contingencies.