For DRIVERS, MECHANICS & FOREMEN.

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS is paid to the sender of any letter which we publish on this page, and an EXTRA FIVE

SHILLINGS to the sender of the one which we select as being the best each week.. All notes are edited before being

published. Mention your employer's name, in •confidence, as evidence of good faith. Address, 0., M. and F., ."The Commercial Motor,' 7-15, Rosebery Avenue, London, E.G. 1.

Lamps Alight.

On Saturday, April 10th, light your lamps at 8.16 in London, 8.34 in Edinhulgh, 8.26 in Newcastle, 8.31 in Liverpool, 8.24 in Birmingham, 8.26 in Bristol, and 1114 in Dublin.

A Wayside Repair to a Frame Member.

The sender of the following communication has been awarded the extra. payment of 5s. this week..

-(2072) "H.S." (Oston) writes It is rarely pos sible to repair a broken frame, when the breakage happens on the road, as, of course, it -invariably

, does. Fortunately, it is, nowadays, almost as rare for a frame to break at all, so that honours, if not even, are not very unequal. However, the unexpected in this regard happened to me recently, and as I was able to improvise a temporary repair, sufficient at least to get me home, a description xif the method which_ I employed may not be uninteresting to your readers.

The breakage occurred in the usual place, quite close to the driver's seat, on the near side. I used the doctor's methods, fixed it up in splints, and put it in a sling. Reference to the sketch—[Which we have had redrawn.—ED.1—will help readers to understand my story. For the splints 1 used a couple of good stout timbers, placing one on the top member of the frame, and one under the lower flange. Before securing them in place, which I did with rope, I took out my jack, and placed it under the frame, upside down, holding it in place with the same ropes that were used to bind the splints. I had a piece of steel cable in the tool-box, this I tied to the_spring brackets, as shown in the sketch, having madeit of such a, length that when laid over the free end of the jack, which was screwed down to its lowest position, the cable was taut. I then. screwed the Jack up so that in conjunctiv with the cable it acted as a, stiffener or truss for the frame. The job waea most satisfactory one and. lasted for quite a long time."

Starting Without a Handle.

(2073) " S.H.B." (Stokenchurch) -writes:—(` I had an unfortunate accident the other day which might, as a, result, have held me up for quite a considerable time. I was turning the lorry round in a narrow country lane when the starting handle became entangled with &projecting ba,ulk of wood and broke off short in such a manner that I could not repair it there and thbn by any expedient. Of course, in the general excitement, I managed to step my engine, so that something had to be done if I was going to get home that night. Fortunately I had a good jack on board, and with it I lifted up one of the rear wheels, leaving the other on the ground. I,then fixed chocks in front of the wheels on the ground, put the engine into top gear, and gave a swing to the elevated rear wheel.. The 'result was quite satisfactory; the engine started at the first pull. "When starting by this means, and more particularly if the vehicle be a light one, it is -essential to use chocks for the rear wheel which is on the ground, otherwise pulling the back wheel round, and also the vibration of the engine when this-starts, may quite easily make the vehicle overrun the jack, with the result that, if the engine is running slowly, the vehicle will stop, or if it is ranning,fast, it is quite possible that the vehicle may be jerked a yard or two, unless something goes in the transmission, both of which events mayhave drastic re-suits, particularly theformer if the space available is limited."

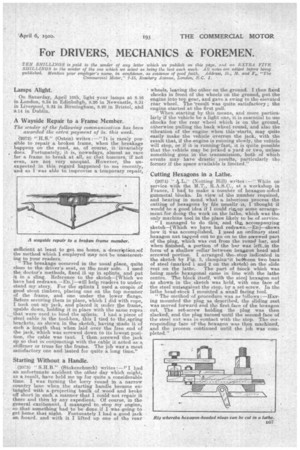

Cutting Hexagons in a Lathe.

(2074) ." 4.14." (Notting Hill) writes:—' While on service with the MT., R.A.S.C., at a workshop in France, I had to make a number of hexagon-sided gunmetal blocks. In view of the number required, and bearing in mind what a.. laborious process the cutting of hexagons by file usually -is, I'thought it would be a goad idea if I could rigop some arrangement for doing the work on the lathe, which was the only machine tool in the place likely to be of service. "I managed to do this, and the, accompanying sketch—{Which we have had redrawm—Enj—shows how it was accomplished. I used an ordinary steel _hexagon nut tapped out to go on to the screwed part of the plug, which was cut from the round bar, and when finished, a portion ef the bar was left_in the form of a shallow collar between hexagon head and screwed portion. I arranged:the...stop indicated in the sketch by Fig. 3, clanapingcit betikeen two bars of steel (marked 1 and 2 on the sketch) on the slide rest on the lathe. The part of block which was being made hexagonal came in line with the lathe centre. The block itself, with the steel hexagon nut as shown in the sketch was held, with one face of the steel nuteagainst the stop, by a set-screw. In the lathe head-stock I mounted a small facing tool.

" The method of procedure was as follows :—Having mounted the plug as described, the sliding rest was moved forward and the first face of the hexagon cut. The set-screw holding the plug was then slacked, and the plug turned until the second face of the steel nut was in contact with the stop. The currespcinding face ofthe hexagon was then machined, and the process continued until the job was completed."