Diesel Engines for Commercial Chassis.

Page 7

Page 8

If you've noticed an error in this article please click here to report it so we can fix it.

The Principle upon which the Deisel Engine Operates has Not to Date been Adopted Successfully for Use on Commercial Chassis. It is More than Probable that such a Development Will Occur, and Should It Do So it will Provide a Very Useful Fuel Alternative as a Set-off to Petrol. A Great Many of Our Readers may Hardly Know What Is Meant by the Diesel Principle ; it is Important that They Should Do So. We have had the Article Herewith Written for us in Simple Language with that Object in View.

Little progress has as yet been made . as to the development of the i Diesel engine in making it suitable for installing n commercial chassis. The cost of petrol as fuel for trade vehicles is a considerable item in the running costs, and there is no doubt that a vehicle propelled by an engine working on the Diesel principle, using heavy oil as fuel, would be a boon to users of that class of machine.

Regarding the ultimate development and application of the Diesel principle on a large scale, it is the opinion of most experts that a still greater future exists for this type of engine. Large engines of this class are already used on a wide scale for factory and marine purposes, and it is extensively used for comparatively small powers in various branches of industry. Big strides have been made in the improvement of the design, especially in the larger classes, but the difficulties of design undoubtedly increase as the size of the engine decreases. These difficulties will no doubt in time be overcome as more experience is gained. Some of the disadvantages of the engine will be obvious if we turn to the engine itself..

The principle of working is as follows : The engine is mai_e three forms, viz., as a four-strokecycle single-acting engine, as a two-stroke-cycle single-acting, and as a two-stroke double-acting engine. An essential feature in the actual Diesel engine is that it requires, besides its own cylinders and pistons, an auxiliary air compressor capable of producing a pressure of tip to 700 lb. per sq. in. The principal difference between the Diesel cycle and the ordinary petrol-engine cycle is that air only is compressed in the cylinder instead of .a mixture of air and fuel, as in the petrol or paraffin engine.

In the four-stroke Diesel engine there is an air inlet valve, a fuel • valve, an exhaust valve worked by cams, and a valve for starting purposes. The arrangement will be understood by referring to Fig. 2. The cycle of operations is as follows :— First (down) stroke.—The inlet valve is opened during the whole of the stroke, and the cylinder becomes filled with atmospheric air at atmospheric pressuee.

Second stroke.—The air valve is closed and the piston returns to the top of the cylinder compressing the air. The clearance is so proportioned that in ordinary working the pressure .becomes about 500 lb. per sq. in. and the temperature of the air about 1000 degrees Fahrenheit. Near the end of the stroke a quantity of fuel is injected through the fuel valve into the cylinder by means of a blast of compressed air supplied from the auxiliary air compressor. The construction of the fuel valve is such that the oil is divided into a spray of fine particles. These, coming into contact with the very hot air, ignite automatically, and combustion takes place, increasing the pressure in the cylinder.

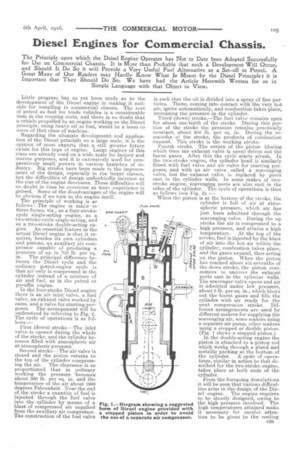

Third (down) stroke.—The fuel valve remains open for about one-tenth of the stroke. During this portion of the stroke the pressure remains practically constant, about 600 lb. per sq. in. During the reinainder of the stroke; the products. of combustion expand. This stroke is the working stroke. Fourth stroke. -The return of the .piston (during which time tee exhaust valve is open) drives out the burnt gases. After this the cycle starts afresh. In the two-stroke engine, the cylinder head is similarly fitted with fuel valve and air valve for starting purposes, and with an air valve called a scavenging valve, but the exhaust valve is replaced by ports cast in the cylinder walls. In some makes of twostroke engine, scavenging ports are also cast in the sides of the cylinder. The cycle of operations is then as follows (see Fig. 3). :— When the piston is at the bottom of the stroke, the cylinder is full of air at atmospheric pressure, which air has just been admitted through the scavenging valve. During the up stroke the air is compressed to a high pressure, and attains a high teniperature. At the top of the stroke, fuel is injected by the bla.st of air into the hot air within the. cylinder, combustion takes place, and the gases expand, thus acting on the piston. When the piston, has reached about six-sevenths of the down stroke, the piston commences to uncover -the exhaust ports cast. in the cylinder walls. The scavenger valve opens and air is admitted under low pressure, about 5 lb. per sq. in., which blows out the burnt gases and fills the cylinder with air ready for the next compression stroke. Different arrangements are used by different makers for supplying the scavenging air, some makers using a separate air pump, other makers using a stepped or double piston. (Fig. 1 shows a stepped piston.)

In the double-acting engine the piston is attached to a piston rod which works through a gland and metallic packing at the bottom of the cylinder, Acycle of operations, similar in action to that described for the two-stroke engine, takes place at both ends of the cylinder.

From the foregoing descriptions it will be seen that various difficulties arise in the design of the Diesel engine. The engine requires to be stoutly designed, owing to the high pressure involved. The high temperatures attained make it necessary for careful attention to be given to the cooling of the various parts of the engine, and the air compressors necessary for supplying the air for starting purposes and for fuel injection, and the fuel valves themselves, all present difficulties which, although overcome in large engines, tend to put the Diesel engine at a great disadvantage when used for comparatively small powers.

Various makes of small-power, send-Diesel engines have appeared which require no compressors for starting or injecting the fuel. These engines have a much lower compression than the purely Diesel engine, varying from about 120 lb. to 200 lb. per sq. in., but they require blow-lamps to heat up the cylinder heads for starting purposes. On the cylinder head a bulb-shaped chamber is formed, which is heated by means of the blow-lamp. Into this chamber the air drawn into the cylinder is compressed. The temperature of the air is increased by the hot bulb and by the increase of the pressure. Fuel is injected into the cylinder by means of an oil pump, and the pressure due to the combustion of the fuel acts on the piston. Various methods have been invented for reducing the compression in small engines intended to work on the Diesel cycle. One of these is illustrated in Fig. 1, showing a section through a two-cylinder, two-stroke engine, having a stepped piston, the larger one acting as an air pump for scavenging. In this particular method the invention is intended to provide a scheme by means of which the engine could be started as an ordinary petrol engine by rotating the crankshaft. It is obvious that in the pure Diesel engine it would be impossible to turn the engine over the centres in such a manner, owing to the high compression. Cast in the cylinder. cover is a chamber (C) which can be put into communication with the working cylinder through the valve (D).

This chamber is used for burning petrol supplied by an ordinary carburetter, and, incidentally, for reducing the high .compression, to that the engine may be started by rotating the crankshaft as in an ordinary petrol engine. A valve is introduced in connection with the inlet valve of the engine, which may allow the engine to draw in pure air, or a mixture from the carburetter.

To start this particular engine, the valve (D) is opened, putting chamber (C) into communication with the cylinder. A mixture of petrol and air is drawn into the chamber (A) through the air inlet on the down stroke of the stepped piston. On the up stroke the gas is transferred into the upper part of the cylinder B) and is compressed into the chamber (C). It is ignited by means of a sparking plug ; the combustion of the gas sets the engine in motion. Heavy oil is now injected into the cylinder through the fuel valve, and the petrol supply is cut off and pure air is drawn into the cylinder The valve (D) is S'hut and the sparking plugs are also put out of action. Exhaust takes place through ports cast in the cylinder walls. The engine is now working on the pure Diesel system.

Such a scheme could probably be applied to the hot-bulb type of engine, so that a, blow-lamp could he dispensed with. The engine would use petrol as fuel until the engine was sufficiently hot for combustion to take place when oil was injected into the air in the cylinder. The petrol supply could then be cut off. After so starting, the engine would run as a hot-bulb engine. It seems probable that if an engine is to be develoPed suitable for use on commercial chassis, it will not run on the pure Diesel cycle, but probably some sort of engine will be evolved that can be started as art ordinary .petrol engine, and afterwards changed over to running on the Diesel or the hot-bulb system, or some combination of these methods. After much experience, a solution to the problem may perhaps he found along these lines, and although the difficulties (which are much greater than appear at first sight) of producing a suitable engine are very great, the proposition is far from hopeless, seeing that the Diesel and semi-Diesel have been adapted to other branches of employment with success.

It is certainly a problem worthy of much thought and experiment on the part of engineers and manufacturers, and in the future we may see many of our motor vehicles running on some modification of the Diesel engine using residual oils as fuel. The high economy of the Diesel and the comparatively cheap' cost of the fuel which can be used would more than compensate for some of the mechanical disadvantages which at present seem to be inseparable from the design