PAINTING BY NUMBERS

Page 92

Page 93

If you've noticed an error in this article please click here to report it so we can fix it.

New regulations coupled with the introduction of two-pack paints will see an end to the brush and paint pot in the corner in return for a major investment in commercial vehicle spray shops.

many operators realise that their vehicles are the most visible part of their business, that's why they want them to be clean and have smart paintwork. But un(ortunately, frequently washed paintwork can fade quickly and vehicles get knocked and scratched during their service life, Even with new vehicles, it's only operators who choose white trucks that avoid paint costs.

In the past, when repairing synthetic (one-pack) paintwork it has been a case of a quick slosh with a paint brush. Now, with the introduction of two-pack and COSHH, it is not so easy; there is no way round spraying two-pack paints without a booth, unless you want to break the law.

Two-pack is not like a traditional paint, it is similar to mixing up an epoxy resin and spraying it on. Once applied the paint undergoes a chemical reaction and hardens rather than dries.

So why are fleet operators moving to two-pack paint? The main reason is that vehicles stay looking good for longer; a two-pack can withstand regular washing without fading for up to five years. That can save the price of a respray for two) and reduces downtime by up to 10 days.

Livery service

However, anyone offering a repainting or livery service must equip accordingly. Under the COSIII1 regulations fresh air breathing equipment must be provided for those spraying the paint: rules concerning solvent emissions are also in the pipeline. The practice of spraying a vehicle in an open shop and leaving it to dry overnight will soon die.

Some forward-thinking operators and paintshops are now looking at installing CV-sized spray booths enabling them to handle the new paints. This is a large investment for any business and to use the booth efficiently it needs to be capable of baking the paint, drying the topcoat in about 40 minutes.

Spray/bake booths for CVs can cost more than £100,000, so they have to be worked hard to get a reasonable return. That's why it is essential to lay out the paintshop for easy throughput. This is not as simple as it might appear as the size of the CV booth often limits its position.

Paint companies, spray booth manufacturers and independents will all offer a prospective CV paintshop owner help. Glasurit, Herberts and ICI, for example, all have bodyshop design consultancies. Charges vary up to £350 although sometimes these are waived. Architects and independents charge full market rate.

The paint companies have started to detect a rise in the number of CV booths being installed. ICI is setting up a network of CV specialists called Fleetwatch (see feature on page 6).

Glasurit's Brian Pye has been involved with bodyshop design for many years. He admits that when he first started work with a booth manufacturer he wanted to minimise the installation work rather than optimise the paintshop design for productivity. Now working for a paint company his work philosophy has reversed: "The more vehicles they spray, the more paint they use," he says.

Tight space

The majority of CV pain tshops are fitted into existing buildings, such as fleet mechanical workshops or car respraying premises, which imposes limitations on the layout. Most people want to fit too many vehicles into the shop," says Herberts' George Rogers. "One roan can push a car but it takes two to manoeuvre a commercial vehicle into a tight space — that's a lot of unproductive time."

It is far better, he says, to have fewer vehicles in the shop making quicker movements and not blowing dust all over the place.

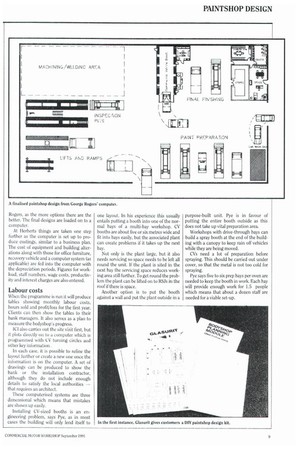

Glasurit produces a bodyshop design kit which contains a board marked with a grid and stick-on spray booths, vehicles, lifts. Although these are based on car sizes, a CV pack should be available soon. A site visit will follow and the design will he transferred to a computer.

Herberts' system transfers measurements from a site visit on to a magnetic board marked with a grid. Walls, roof supports and doors are put in first then the magnetic pieces representing the vehicles (also showing the turning circles) and spray booth are juggled around to find the most efficient positioning.

It is useful to get as many people to take part in this exercise as possible, says

Rogers, as the more options there are the better. The final designs are loaded on to a computer.

At Herberts things are taken one step further as the computer is set up to produce costings, similar to a business plan. The cost of equipment and building alterations along with those for office furniture, recovery vehicle and a computer system (as applicable) are fed into the computer with the depreciation periods. Figures for workload, staff numbers, wage costs, productivity and interest charges are also entered.

Labour costs

When the programme is run it will produce tables showing monthly labour costs, hours sold and profit/loss for the first year. Clients can then show the tables to their bank managers. It also serves as a plan to measure the bodyshop's progress.

ICI also carries out the site visit first, but it plots directly on to a computer which is programmed with CV turning circles and other key information In each case, it is possible to refine lhe layout further or create a new one once the information is on the computer. A set of drawings can be produced to show the bank or the installation contractor, although they do not include enough details to satisfy the local authorities -that requires an architect.

These computerised systems are three dimensional which means that mistakes are shown up easily.

Installing CV-sized booths is an engineering problem, says Pye, as in most cases the building will only lend itself to

one layout. In his experience this usually entails putting a booth into one of the normal bays of a multi-bay workshop. CV booths are about five or six metres wide and fit into bays easily, but the associated plant can create problems if it takes up the next bay.

Not only is the plant large, but it also needs servicing so space needs to be left all round the unit. If the plant is sited in the next bay the servicing space reduces working area still further. To get round the problem the plant can be lifted on to RSJs in the roof if there is space.

Another option is to put the booth against a wall and put the plant outside in a purpose-built unit. Pye is in favour of putting the entire booth outside as this does not take up vital preparation area.

Workshops with drive-through bays can build a spray booth at the end of the building with a canopy to keep rain off vehicles while they are being moved.

CVs need a lot of preparation before spraying. This should be carried out under cover, so that the metal is not too cold for spraying.

Pye says five to six prep hays per oven are needed to keep the booth in work. Each bay will provide enough work for 1.5 people which means that about a dozen staff are needed for a viable set-up.