PUTTING A GLOSS ON IT

Page 103

Page 104

If you've noticed an error in this article please click here to report it so we can fix it.

A CV spray booth will be the most expensive item in any paint shop — so picking the right model is essential.

The economics of setting up a CV spraying business are hardly likely to get the hordes clamouring for a piece of the action. Compared with setting up to spray cars you need four times the space, four times the money and four limes the paint — but you can't charge four times as much for the job.

Because margins are so tight a CV painting business must run at maximum efficiency if it is to be viable. To achieve that efficiency, not only must the paintshop layout be right: you'll also need the right booth.

All CV booths and plant are built to order, usually from modules or standard products. To decide which booth he needs, a wouldbe paintshop manager should start by defining the type of work he expects to undertake. If he is just spraying panel vans then a large car oven would suffice. On the other hand if he only expects to paint trailers or large rigids, it would be wasteful to opt for a versatile, but expensive, oven. Remember that a partitionable booth must have two diagonally opposite escape doors in each section, adding to cost and design problems.

Air changes

A major consideration when specifying your booth is airflow. Manufacturers give differing figures: some say it should be 23m/sec: others suggest 9-14m/sec. Others express their requirement as 3.5-5.5 air changes per minute.

Whatever the figure, note it down and check it with other CV paintshops.

It is desirable for the entire ceiling to act as an air inlet to avoid distorted airflows that can be set up when a tall vehicle is placed under central ducts.

Exhausting air from the booth should be via one or two pits as wall vents take up space. On the two-pit design the vehicle's wheels often run over the gratings which can eventually start to sag. In a single pit design the sprayer can drop into it to paint the bottom of a chassis.

Heating cycle

There are two main heating systems, direct and indirect. In some countries the direct method, whereby air passing over the flame goes into the booth, is being questioned because of the gases that enter the working area. Whichever system is chosen the air should be recirculated on the heating cycle with a 10% bleed off to meet regulations.

Imminent regulations will limit the amount of solvent emission allowed from a paintshop. lithe regs express the contamination limit in quantities per cubic metre of air, then the higher the quantity of air throughput the better. Fans with spare capacity will also be useful if a filter system has to be attached.

Regardless of the terms of the regs, the new generation of low-velocity/high-volume air spray guns will help. They produce less overspray, resulting in lower emissions — and higher profit potential. This is especially useful for CV spraying due to the large quantity of paint required.

Other likely regulations will restrict the proportion of solvent in paint, which will speed up the introduction of water based paints. These paints will not air dry in the UK's humid weather so a booth with a retrofitable climate control capability could be a good bet in the longer term.

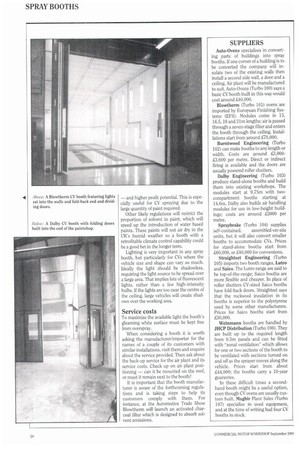

Lighting is very important in any spray booth, but particularly for CVs where the vehicle size and shape can vary so much. Ideally the light should be shadowless, requiring the light source to be spread over a large area. That implies lots of fluorescent lights, rather than a few high-intensity bulbs. If the lights are too near the centre of the ceiling, large vehicles will create shadows over the working area.

Service costs

To maximise the available light the booth's gleaming white surface must be kept free from overspray.

When considering a booth it is worth asking the manufacturer/importer for the names of a couple of its customers with similar installations, visit them and enquire about the service provided. Then ask about the back-up service for the air plant and its service costs. Check up on air plant positioning — can it be mounted on the roof, or must it remain next to the booth?

It is important that the booth manufacturer is aware of the forthcoming regulations and is taking steps to help its customers comply with them. For instance, at the Automotive Trade Show Blowtherm will launch an activated charcoal filter which is designed to absorb solvent emissions.