PATENTS SUMMARIZED.

Page 22

If you've noticed an error in this article please click here to report it so we can fix it.

A Wick Carburetter.

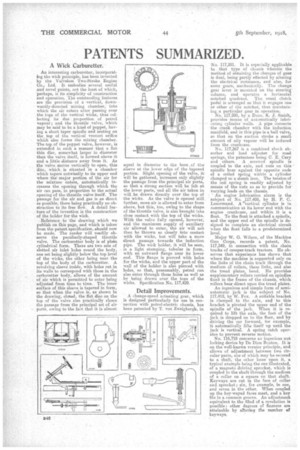

An interesting carburetter, incorporating the wick principle, has been invented by the Valveless Two-Stroke Engine Co., Ltd. It embodies several useful and novel points, not the least of which, perhaps, is its simplicity of construction and operation. The outstanding features are the provision of a vertical, downwardly-directed mixing chamber, into which the air enters after passing over the tops of the vertical wicks, thus collecting its due proportion of petrol vapour; and the throttle valve; which may be said to be a kind of poppet, having a short taper spindle and seating on the top of the vertical venturi orifice which also forms the mixing chamber. The top of the poppet valve, however, is extended in such a manner that a fiat thin disc, somewhat larger in diameter than the valve itself, is formed above it and a little distance away from it. As the valve moves vertically to open, this disc, which is situated in a chamber which tapers outwardly to its upper end where the major portion of the air for the mixture enters, automatically increases the opening through which the air can pass, in proportion to the actual opening of the throttle valve itself. The passage for the air and gas is as direct as possible, there being practically no obstruction to its free flow. A detail feature of the invention is the construction of the holder for the wick.

. Reference to the drawing which we publish on this page, and which is taken from the patent specification, should now be made. The reader will readily observe the peculiarly-shaped throttle valve. The carburetter body is of plain. cylindrical form. There are two sets of slotted air inlet holes round the body, one set being slightly below the top level of the wicks, the other being near the top of the body of the carburetter. A revolving sleeve inside, with holes cut in its walls to correspond with those in the carburetter body, allows of the amount of air which is permitted to enter being adjusted from time to time. The inner surface of this sleeve is tapered in form, BO that when the valve is, as shown in the drawing, closed, the flat disc on the top of the valve also practically closes the passage from the principal set of air ports. owing to the fact that it is almost equal in diameter to the bore of the sleeve at the lower edge of the tapered portion. Slight opening of the valve, it will be gathered, increases only slightly the passage from the principal air ports, so that a strong suction will be felt at the lower ports, and all the air taken in will be drawn directly over the top of the wicks. As the valve is opened still further, more air is allowed to enter from above, but this, too, owing to the shape of the throttle valve, is also brought into close contact with the top of the wicks. With the valve fully opened, however; and the maximum supply of auxiliary air allowed to enter, the air will not then be thrown so closely into contact with the wicks, but will take a more direct passage towards the induction pipe. The wick holder, it will be seen, is a light stamping, tubular in form, with an outward flange near its lower end. This flange is pierced with holes for the wicks, and the upper part of the wall of the holder is also pierced with holes, so that, presumably, petrol can also enter through these holes as well as by being drawn over the tops of the wicks. Specification No.. 117,429.

Detail Improvements.

A change-speed actuating gear, which is designed particularly for use in connettion with petrol-electric chassis, has been patented by T. von ZWeigbergk, in No. 117,291. It is especially applicable to . that type of chassis wherein the method of obtaining the changes of gear is dual, being partly effected by altering the electrical resistance, and also, for sonic gears, mechanically. The change gear lever is mounted on the steering column, and operates a horizontal notched quadrant. The usual clutch pedal is arranged so that it engages one or other of the notches', thus maintaining a particular gear in operation. • No. 117,295, by a Dane, K. J. Smidt, provides means of automatically lubri cating cylinder walls. A pipe connects the crank chamber with the induction manifold, and in this pipe is a hall valve, so that on the suction stroke a small amount of oily vapour will be induced from the crankcase.

No. 117,367 is a combined shock absorber and load adjuster for road springs, the patentees being C. E. Cary and others. A screwed spindle is coupled to the axis, and nuts on this spindle bear against the opposite ends of a coiled spring within a cylinder clamped to a dumb iron. The tension of the coil spring is readily adjusted by means of the nuts so as to provide for varying loads on the chassis.

' An engine lubrication alarm is the subject of No. _117,408, by H. P. C. Lennrmand. A 'vertical cylinder is in communication at its lower end with the engine crankcase, and within it is a float. To the float is attached a spindle, and the upper end of the spindle is designed to complete an electrical circuit when the float falls to a predetermined level.

Major W. G. Wilson, of the Machine Gun Corps, records a patent, No.

117,349, in connection with the chain tracks of creeper-track tractors. He observes that experience has shown that where the machine is supported only on the links of the chain track through the medium ca rollers, these links, and also the tread plates, bend. He provides supplementary rollers carried on spindles fixed in the frame of the chassis, which rollers bear direct upon the tread plates. An ingenious and simple form of semiautomatic jack is the subject of No. 117,412, by W. Fox. A suitable bracket is clamped to the axle, and ' to this bracket is pivoted the upper end of the spindle of the jack. When it is re quired to lift the axle, the foot of the jack is dropped on to the floor, and by driving the car forward, for example, it automatically lifts itself up until the jack is vertical. A spring catch operates to prevent reverse motion.

No. 116,719 concerns an ingenious nut. locking device by De Dion Bo.uton. It is

on the well-known vernier principle, and allows of adjustment between two circular parts, one of which may be secured to a shaft., the other loose upon it, a typical example being the one illustrated, of a magneto driving sprocket, which is coupled to the shaft through the medium of a collar on a square on that shaft. Keyways are cut in the face of collar and sprocket; six, for example, in one, and seven in the other. When coupled up the key-wayed faces meet, and a key fits in a common groove. An adjustment equivalent to the 42nd of a revolution is possible other degrees of fineness are attainable by altermg the number of keyways.