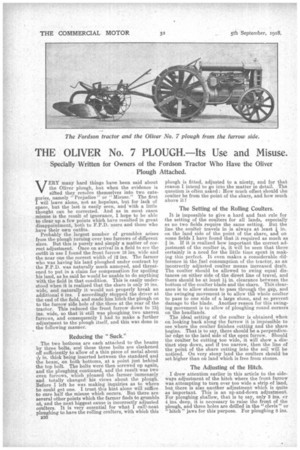

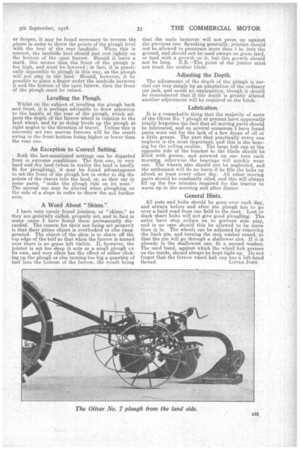

THE OLIVER No. 7 PLOUGH.—Its Use and Misuse.

Page 10

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

Specially Written for Owners of the Fordson Tractor Who Have the Oliver Plough Attached.

VERY many bard things have been said about the Oliver plough, but when the evidence is sifted they resolve themselves into two categories, namely " Prejudice " or "Misuse.!' The first I will leave alone, not as hopeless, but for lack of space, but the last is easily seen, and with a little thought can be corrected. And as in most cases misuse is the result of ignorance, I hope to be able to clear up a few points which have resulted in great disappointment, both to F.P.D. users and those who have their awn outfits.

Probably the largest number of grumbles arises from the plough turning over two furrows of different sizes. But this is purely and simply a matter of correct adjustment. Once on arrival in a field to see the outfit in use I found the front furrow 16 ins, wide and the near one the correct width of 12 ins. The farmer who was having his land ploughed under contract by the F.P.D. was naturally much annoyed, and threatened to put in a claim for compenss;tion for spoiling his land, as he said he would be unable to do anything with the field in that condition. This is easily understood when it is realized that the share is only 10 ins. wide, and naturally it would not properly break an additional 6 ins. I accordingly stopped the driver at the end of the field, and made him hitch the plough on to the furrow side hole of the three at the rear of the tractor. This reduced the front furrow down to 14 ins, wide, so that it still was ploughing two uneven furrows, and consequently I had to make a, further adjustment to the plough itself, and this was done in the following mariner.

Reducing the "Suck."

The two bottoms are each attached to the beams by three bolts, and these three bolts are slackened off sufficiently to allow of a thin piece of metal about sls in. thick being inserted between the standard and the beam on both .bottoms, at a point just behind the top bolt. The bolts were then screwed up again, and the ploughing continued, and the result was two even furrows, which pleased the farmer immensely and totally changed his views about the plough. Before I left he was making inquiries as to where he could get one. I trust this hint alone will suffice to cure half the misuse which occurs. But there are several other points which the farmer finds to grumble at, and the next biggest cause is incorrectly adjusted coulters. It is very essential for what I call' neat ploughing to have the rolling coulters, with which this

B30 plough is fitted, adjusted to a nicety, and for that reason I intend to go into the matter in detail. The question is often asked : How much offset should she coulter be from the point of the share, and how much above it 1

The Setting of the Rolling Coulters.

It is impossible to give a hard and fast rule for the setting of the coulters for all lands, especially as no two fields require the same setting. .But the line the coultel. travels in is always at least in. on the land side of the point of the share, and on some fields I have found that it required as much as

in. If it is realized how important the correct adjustment of the coulter is, it will be seen that there certainly is a need for the little time spent in making this perfect. It even makes a considerable difference in the fuel consumption of the tractor, as an incorrectly adjusted coulter means increased draft. The coulter should be allowed to swing equal distances on either side of the direct line of travel, and there should be at least i in. clearance between the bottom of the coulter blade and the share. This clearance is to allow stones to pass througlh the gap, and the swinging movement is to allow the whole coulter to pass to one side of a large stone, and so prevent damage to the blade. Another reason for this swinging movement is to allow of ploughing round corners on the headlands.

• The ideal setting of the coulter is obtained when on looking back along the furrow it is impossible to see where the coulter finishes cutting and the share begins. That is to say, there should be a, perpendicular edge to the land side of the open furrow. Should the coulter be cutting too wide, it will show a tinct step down, and if too narrow, then the line of the point of the share cutting into the soil will be noticed. On very stony land the coulters should be set higher than on land which is free from stones.

The Adjusting of the Hitch.

I drew attention earlier in this article to the sideways adjustment of the hitch where the front furrow was attemptmg to turn over too wide a strip of land, but there is also another adjustment which is quite as important. This is an up-and-down adjustment. For ploughing shallow, that is to say, only 3 ins. cr 4 ins, deep, it is necessary to raise the front of the plough, and three holes are drilled in the "clevis " or " hitch " jaws for this purpose. For ploughing 8 ins. or deeper, it may be found necessary to reverse the plates in order to throw the points of the plough level with the heel of the rear landside. When this is correct, the landside heel should just rest lightly on the bottom of the open furrow. Should it leave a mark, this means that the front of the plough is too high, and must be lowered ; in fact, it is practically impossible to plough in this way, as the plough will not stay in the land. Should, however, it be possible to place a finger under the landside between it and the bottom of the open furrow, then the front of the plough must be raised.

Levelling the Plough.

Whilst on the subject of levelling the plough back and front, it is perhaps advisable to draw attention to the handle at the rear of the plough, which adjusts the depth of the furrow wheel in relation to the land wheel, and by so doing levels up the plough at right angles to the direction of travel. Unless this is correctly set two uneven furrows will be the result owing to the front bottom being higher or lower than the rear one.

An Exception to Correct Setting.

Both the last-mentioned settings can be departed from in extreme conditions. The first one, in very hard and dry land (when in reality the land is hardly fit for ploughing), it may be found advantageous to set the front of the plough low in order to dig the points of the shares into the land, or, as they say in some parts, "make the plough ride on its nose!' The second one may be altered when ploughing on the side of a slope in order to throw the soil further over.

A Word About "Skims."

I have very rarely found jointers, or "skims," as they are generally called, properly set, and in fact in many cases I have found them permanently discarded. The reason for their not being set properly is that their prime object is overlooked or else exaggerated. The object of the skim is to shave off the top edge of the turf so that when the furrow is turned over there is no grass left visible. If, however, the jointer is set too deep it acts as a small plough cn its own, and very often has the effect of either choking up the plough or else turning too big a quantity, of turf into the bottom of the furrow, the result being that the main turnover will not press. up against the previous one. Speaking generally, jointers should not be allowed to penetrate more than 1 in. into the ground, and should not be used except on grass land, or land with a growth on it, but this growth should not be long. N.B. —The point of the jointer must not touch the coulter blade.

Adjusting the Depth.

The adjustment of the depth of the plough is carried out very simply by an adaptation of the ordinary ear jack, and needs no explanation, though it should be remembered that if the depth is greatly altered another adjustment will be required at the hitch.

Lubrication.

It is a remarkable thing that the majority of users of the Oliver No. 7 plough at present have apparently totally forgotten the fact that all moving parts should be lubricated, and on several occasions I have found parts worn out for the lack of a few drops of oil or a little grease. The part that practically every one neglects is the most important, and this is the bearing for the rolling coulter. The large hub cap at the opposite side of the bracket to the blade should be filled with grease, and screwed up one turn each morning, otherwise the bearings will quickly wear out. The wheels also should not be neglected, and the enthusiast will do no harm if he fills the hubs up afresh at least every other day. All other moving parts should be constantly oiled, and this will always fill up the few minutes required for the tractor to warm up in the morning and after dinner.

General Hints.

All nuts and bolts should be gone over each day, and always before and after the plough has to go over a hard road from one field to the next. Lost or slack share bolts will not give good ploughing. The axles have stop collars on to prevent side play, and in no case should this be allowed to be more than lig in. The wheels can be adjusted by removing the linch pin, and turning the step washer round, so that the pin will go through a shallower slot. If it is already in the shallowest one, fit a second washer. The sand band, against which the wheel hub presses on the inside, should always be kept tight up. Do not forget that the furrow wheel hub cap has a left-hand

thread. LITTLE JOHN.