LEADER HOLDS ON TO ITS LOAD

Page 59

Page 60

If you've noticed an error in this article please click here to report it so we can fix it.

The Tautliner set the pace for curtainsided bodies 16 years ago, and the pattern for future Boalloy developments. Bill Brock takes a look at an original design which is still being copied.

BECAUSE Tatliner was the first modern curtainsider does not automatically mean that it is still the best, but as competitors still try to copy the original after 16 years, it might just be true.

The story of Tautliner is one of continuous development since 1969. Before then the best curtainsider could only be expected to keep the cargo dry; loads had to be roped for security.

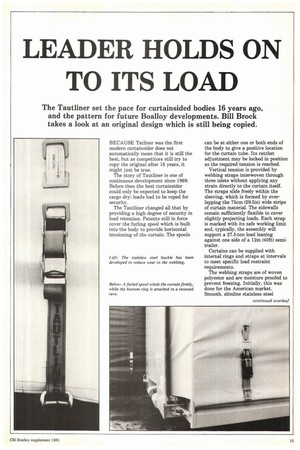

The Tautliner changed all that by providing a high degree of security in load retention. Patents still in force cover the furling spool which is built into the body to provide horizontal tensioning of the curtain. The spools can be at either one or both ends of the body to give a positive location for the curtain tube. Its ratchet adjustment may be locked in position as the required tension is reached.

Vertical tension is provided by webbing straps interwoven through three islets without applying any strain directly to the curtain itself. The straps slide freely within the sleeving, which is formed by overlapping the 75cm (29.5in) wide strips of curtain material. The sidewalls remain sufficiently flexible to cover slightly projecting loads. Each strap is marked with its safe working limit and, typically, the assembly will support a 27.5-ton load leaning against one side of a 12m (40ft) semitrailer.

Curtains can be supplied with internal rings and straps at intervals to meet specific load restraint requirements.

The webbing straps are of woven polyester and are moisture proofed to prevent freezing. Initially, this was done for the American market. Smooth, slimline stainless steel buckles were then developed to reduce strap wear. The lower end of each strap terminates in a closed rave hook, designed to avoid snagging on the curtain or operative's clothing.

In conventional raves the hooks project along the side of the vehicle. In confined spaces, such as ferries, they can rub and snag. Boalloy's stepped side rave gives full protection against this.

At the top end of each strap are high-tensile steel rings. These are waisted, giving a profile which hugs the nylon bobbin rollers and ensures positive alignment within the curtain track.

The standard Tautliner, built to a high specification, meets the requirements of 75 per cent of Boalloy's customers. Most are built on Crane Fruehauf, M and G, Trailor or Van Hool semi-trailers with suitable front and rear cross-member configurations. Indeed, Tautliners are conventionally thought of as 40ft semi-trailers, but the company also builds its curtain sided bodywork on all sizes of rigid chassis.

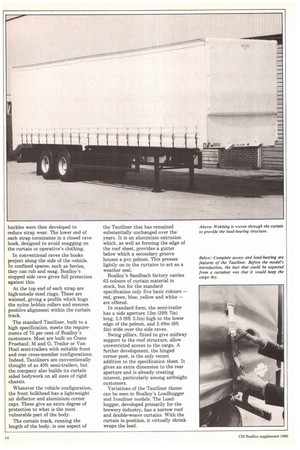

Whatever the vehicle configuration, the front bulkhead has a lightweight air deflector and aluminium corner caps. These give an extra degree of protection to what is the most vulnerable part of the body.

The curtain track, running the length of the body, is one aspect of the Tautliner that has remained substantially unchanged over the years. It is an aluminium extrusion which, as well as forming the edge of the roof sheet, provides a gutter below which a secondary groove houses a pvc pelmet. This presses lightly on to the curtains to act as a weather seal.

Boalloy's Sandbach factory carries 63 colours of curtain material in stock, but for the standard specification only five basic colours — red, green, blue, yellow and white — are offered.

In standard form, the semi-trailer has a side aperture 12m (39ft 71n) long, 2.5 (8ft 2.5in) high to the lower edge of the pelmet, and 2.49m (8ft 2in) wide over the side raves.

Swing pillars, fitted to give midway support to the roof structure, allow unrestricted access to the cargo. A further development, the hinged corner post, is the only recent addition to the specification sheet. It gives an extra dimension to the rear aperture and is already creating interest, particularly among airfreight customers.

Variations of the Tautliner theme can be seen in Boalloy's Loadhugger and Insuliner models. The Loadhugger, developed primarily for the brewery industry, has a narrow roof and double-weave curtains. With the curtain in position, it virtually shrink wraps the load.