KEEPING COOL BEHIND CURTAINS

Page 57

Page 58

If you've noticed an error in this article please click here to report it so we can fix it.

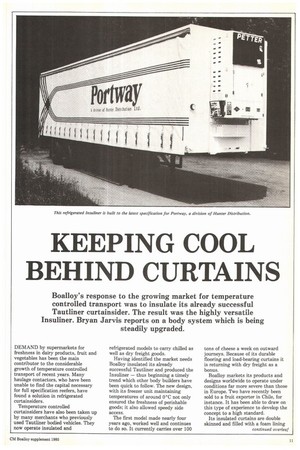

Boalloy's response to the growing market for temperature controlled transport was to insulate its already successful Tautliner curtainsider. The result was the highly versatile Insuliner. Bryan Jarvis reports on a body system which is being steadily upgraded.

DEMAND by supermarkets for freshness in dairy products, fruit and vegetables has been the main contributor to the considerable growth of temperature controlled transport of recent years. Many haulage contactors, who have been unable to find the capital necessary for full specification reefers, have found a solution in refrigerated curtainsiders.

Temperature controlled curtainsiders have also been taken up by many merchants who previously used Tautliner bodied vehicles. They now operate insulated and refrigerated models to carry chilled as well as dry freight goods.

Having identified the market needs Boalloy insulated its already successful Tautliner and produced the Insuliner — thus beginning a timely trend which other body builders have been quick to follow. The new design, with its freezer unit maintaining temperatures of around 0°C not only ensured the freshness of perishable goods; it also allowed speedy side access.

The first model made nearly four years ago, worked well and continues to do so. It currently carries over 100 tons of cheese a week on outward journeys. Because of its durable flooring and load-bearing curtains it is returning with dry freight as a bonus.

Boalloy markets its products and designs worldwide to operate under conditions far more severe than those in Europe. Two have recently been sold to a fruit exporter in Chile, for instance. It has been able to draw on this type of experience to develop the concept to a high standard.

Its insulated curtains are double skinned and filled with a foam lining of closed-cell air bubbles which are moisture resistant. The inner surface of the curtains is lined with a taintfree material. Standard sleeved tensioning straps are used.

Special care has been taken to ensure full air sealing of the curtains. At the bottom a patent double-stage side rave is used. At the head, maximum cold air retention at the top rail is achieved by fitting double weather pelmets which press firmly to the curtains.

Additional reinforcement of the 152mm (6in)-thick bulkhead allows it to take the extra weight of a freezer with external evaporator. There are no internal intrusions so that 22 pallets (44 if double stacked) of chilled or dry-freight goods can be carried.

Rear doors are a standard 75mm (3in) thick. These are double sealed and fitted with anti-rack locking bars and hinges.

Boalloy is continually developing the design. This includes full-scale thermal tests and thermographic exposure work. After a seminar on refrigeration a few years ago, managing director Gerald Broadbent became concerned at the rapid deterioration of the insulation of controlled temperature reefers and containers which can occur when large single panels flex.

"I can now appreciate why certain countries are highly suspicious of thin-wall bodies," he said. "Constant flexing breaks insulation down alarmingly and the resulting loss of efficiency can go undetected for too long."

With this in mind Boalloy has invested £52,000 in machinery to produce its own insulated panels and foam lining. All Insuliners now have 2.4 X 1.2m (8 X 4ft) interlocking roof panels of 75mm (3in) thickness. Their tongue and groove edges allow the structure to absorb the twist and racking effects of severe road use.

The insulated floors have the same degree of flexibility.

Recognition of Boalloy's marketing and innovative design came in 1982, when the Insuliner was awarded the Institute of British Carriage and Automobile Manufacturers' gold medal, beating off competition from conventional refrigerated box vans.

Because of the tremendous success of the Tautliner and the pressures it has placed on the company the Insuliner has yet to reach its full market potential, Boalloy believes. This is rapidly changing, however. Many customers who previously operated Tautliners now use insulated versions, and Boalloy is finding a ready market for refrigerated Insuliners.

This also applies to its rigid truck mounted Insuliner and Linkliner sliding-side bodies.

Boalloy has now become firmly established as a producer of temperature controlled transport. It has every intention of occupying the same market position with it as it does with dry freight distribution bodywork.

"We have the equipment and the staff to ensure it," adds Mr Broadbent.