FULL SIDE ACCESS WITH SECURITY

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

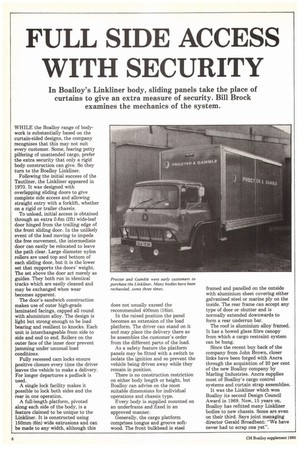

In Boalloy's Linkliner body, sliding panels take the place of curtains to give an extra measure of security. Bill Brock examines the mechanics of the system.

WHILE the Boalloy range of bodywork is substantially based on the curtain-sided designs, the company recognises that this may not suit every customer. Some, fearing petty pilfering of unattended cargo, prefer the extra security that only a rigid body construction can give. So they turn to the Boalloy Linkliner.

Following the initial success of the Tautliner, the Linkliner appeared in 1970. It was designed with overlapping sliding doors to give complete side access and allowing straight entry with a forklift, whether on a rigid or trailer chassis.

To unload, initial access is obtained through an extra 0.6m (2ft) wide-leaf door hinged from the trailing edge of the front sliding door. In the unlikely event of the load moving to impede the free movement, the intermediate door can easily be relocated to leave the path clear. Large diameter nylon rollers are used top and bottom of each sliding door, but it is the lower set that supports the doors' weight. The set above the door act merely as guides. They both run in identical tracks which are easily cleaned and may be exchanged when wear becomes apparent.

The door's sandwich construction makes use of outer high-grade laminated facings, capped all round with aluminium alloy. The design is light but strong enough to be load bearing and resilient to knocks. Each unit is interchangeable from side to side and end to end. Rollers on the outer face of the inner door prevent jamming under unusual load conditions.

Fully recessed cam locks ensure positive closure every time the driver leaves the vehicle to make a delivery. For longer departures a padlock is used.

A single lock facility makes it possible to lock both sides and the rear in one operation.

A full-length platform, pivoted along each side of the body, is a feature claimed to be unique to the Linkliner. It is constructed using 150mm (6in) wide extrusions and can be made to any width, although this does not usually exceed the recommended 400mm (16in).

In the raised position the panel becomes an extension of the load platform. The driver can stand on it and may place the delivery there as he assembles the customer's order from the different parts of the load.

As a safety feature the platform panels may be fitted with a switch to isolate the ignition and so prevent the vehicle being driven away while they remain in position.

There is no construction restriction on either body length or height, but Boalloy can advise on the most suitable dimensions for individual operations and chassis type.

Every body is supplied mounted on an underframe and fixed in an approved manner.

Generally, the cargo platform comprises tongue and groove softwood. The front bulkhead is steel framed and panelled on the outside with aluminium sheet covering either galvanised steel or marine ply on the inside. The rear frame can accept any type of door or shutter and is normally extended downwards to form a rear underrun bar.

The roof is aluminium alloy framed. It has a bowed glass fibre canopy from which a cargo restraint system can be hung.

Since the recent buy back of the company from John Brown, closer links have been forged with Ancra through the acquisition of 20 per cent of the new Boalloy company by Marling Industries. Ancra supplies most of Boalloy's cargo control systems and curtain strap assemblies.

It was the Linkliner which won Boalloy its second Design Council Award in 1969. Now, 15 years on, Boalloy has refitted many Linkliner bodies to new chassis. Some are even on their third. Says joint managing director Gerald Broadbent: "We have never had to scrap one yet".