An Improved Gasifier for heavy fuels

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

An Instrument that Employs External Combustion for Generating Gas from Heavy Oils for Use in Internal-combustion Spark-ignition Engines

T"generation of gas from vaporizing oil by bringing the oil into direct contact with independently produced hot gases is the principle employed in the Rector Gasifier, made in Waukesha, U.S.A.., and now handled in this country by the Br-amber Engineering Co., Ltd., Waterloo Road, Cricklewood, London, N.W.2. The device, in its original form, was described in The Commercial Motor in January, 1932, but since then numerous improvements have been effected.

The maker states that it is incorrect to call the instrument a vaporizer—the term usually applied to apparatus for enabling petrol engines to run on heavy fuels—because the process is claimed to subject the fuel to both physical and chemical changes so that the resultant gases do not readily condense. The intense heat to which the fuel is raised is said to have a cracking rather than a purely vaporizing effect.

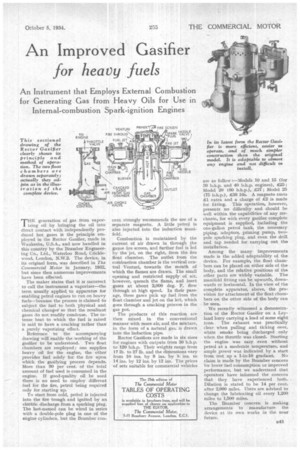

Reference to the accompanying drawing will enable the working of the gasifier to be understood. Two float chambers are employed; one supplies heavy oil for the engine, the other provides fuel solely for the fire upon which the gasifying process depends. More than 90 per cent. of the total amount of fuel used is consumed in the engine. If good-quality oil be used there is no need to employ different fuel for the fire, petrol being required only for starting up.

To start from cold, peti-ol is injected into the fire trough and ignited by an eleetric discharge from a sparking plug. The last-named can be wired in series with a double-pole plug in one of the engine cylinders, but the Bramber con

cern strongly recommends the use of a separate magneto. A little petrol is also injected into the induction manifold.

Combustion is maintained by the current of air drawn in through the gauze fire screen, and further fuel is fed by the jet, on the right, from the fire float chamber. The outlet from the combustion chamber is the vertical central Venturi, towards the mouth of which the flames are drawn. The small opening and restricted supply of air, however, quench the flame, and inert gases at about 2,000 deg. F. flow through at high speed. In their passage, these gases pick up fuel from the float chamber and jet on the left, which goes through a cracking process in the gas pot.

• The products of this reaction are then mixed in the conventional manner with more air, and the mixture, in the form of a natural gas, is drawn into the induction pipe.

Rector Gasifiers are made in six sizes for engines with outputs from 30 b.h.p. to 120 b.h.p. Their weights range from 17 lb. to 27 lb. and the dimensions vary from 10 ins. by 9 ins. by 8 ins. to 14 ins. by 12 ins. by 12 ins. The prices of sets suitable for commercial vehicles are as follow :—Models 10 and 15 (for 30 b.h.p. and 40 b.h.p. engines), £25; Model 20 (60 b.h.p.), £27; Model 25 (75 b.h.p.), £30 10s. A magneto costs £1 extra and a charge of £2 is made for fitting. This operation, however, presents no difficulty and should be well within the capabilities of any mechanic, for with every gasifier complete equipment is supplied, including the one-gallon petrol tank, the necessary piping, adapters, priming pump, twopole sparking plug, and even the drill and tap needed for carrying out the installation.

Among the many improvements made is the added adaptability of the device. For example, the float chambers can be placed on either side of the body, and the relative positions of the other parts are widely variable. The manifold fitting can be upwards, downwards or horizontal. In the view of the complete apparatus, above, the provision for attachment of the float charnbers on the other side of the body can be seen.

We recently witnessed a demonstration of the Rector Gasifier on a Leyland lorry carrying a load of some eight tons. The exhaust was practically clear when pulling arid ticking over, white smoke being discharged only when the throttle was closed. Starting the engine was easy even without petrol at a moderate temperature, and ample power was indicated by a start from rest up a 1-in-10 gradient No claim is made by the Bramber concern for lower fuel consumption or improved performance, but we understand that operators have informed the concern that theyhave experienced both. Dilution is stated to be 14 per cent. after 2,000 miles. Users are advised to change the lubricating oil every 1,200 miles to 1,500 miles.

The Bramber concern is making arrangements to manufacture the device at its own works in the near future,