WAYS AND MEANS.

Page 67

If you've noticed an error in this article please click here to report it so we can fix it.

Useful Contributions From Our Driver and Mechanic Readers

THE following useful tip is sent by " C.H.J.," of Exeter :—The fitting of keys is not an easy matter, even when' done by men who are well used to such work and when done by a driver who has to do the best he can without much practice, and with a very indifferent kit of tools it is still more difficult. To add to these difficulties, the motor driver-mechanic has so often to fit keys to taper shafts, which is a more difficult job than with a parallel shaft, and is one that is not often met with outside motor work. Some good fitters would not find it easy to fit such a key and be sure that it is bearing properly and yet is not throwing the boss out of truth.

As in most other mechanical matters, there is a right way and there is a wrong way of setting about it, and in this case there is only one way of doing the job properly.

The shaft should be held tightly in the vice, and the part, such as a universal joint or sprocket wheel, to be keyed on should be driven on as hard as possible ; when in place a plain mark with a hard scriber should be made on the shaft, showing how far the boss goes on the taper. The boss should then be removed, and the key fitted tightly in the recess made for it in the shaft. Care should be taken that the corners of the key are well bevelled, as the cutters which form the key seating can never keep a perfectly sharp corner, so there is always a radius where the sides of the recess meet the bottom. It is the neglect of this point that is responsible for much bad key fitting, as if the edges of the key be not bevelled it will not be possible to ensure the key reaching the bottom of the recess.

When the key is fitted, and well driven into its recesS, the boss should then be offered on to the shaft. If matters be as they should it will not go on the taper up to the scriber mark. The inside of the keyway in the boss should then be smeared with some colour so that it will leave a mark where it bears on the key and show where metal should be filed off the key. Here, again, bevelling of the key edges is necessary, as a key that only bears on its extreme edges is no good. By gradual stages the key can be brought to a perfect fit and at the same time allow the boss to come home to the scriber mark, which is an indication that all is correct, that the boss is bearing on conical part and key evenly and that the boss win be running true on its shaft.

How to Avoid Slipping Fan Belts.

MOST drivers have at some time or

other been troubled with slipping fan belts. This trouble is often not easy to diagnose, as a fan may appear to be running at its proper speed whilst in reality it may be revolving at only 75 per cent, of its original speed.

Boiling troubles are often due to fanbelt slip, and the eye is not always able to detect the diminished speed.

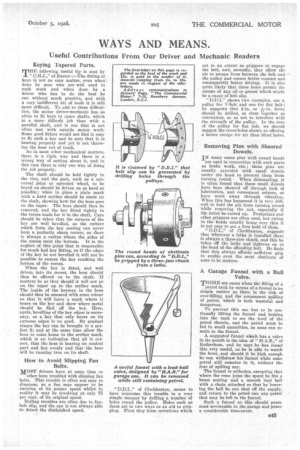

" D.D.I.," of Cleckheaton, seems to have overcome this trouble in a very simple manner by drilling a number of holes round the pulley. Holes such as these act in two ways as an aid to gripping. First they form serrations which

act to an extent as grippers to engage the belt, and, secondly, they allow the air to escape from between the belt and the pulley and ensure better contact and consequently better driving. It is also quite likely that these holes permit the escape _of any oil or grease which might be a cause of belt slip.

" D.D.I." shows two examples, one a Pulley for V-belt and one for fiat belt ; he suggests that fin, or h-in. holes should be drilled, as close together as convenient, so as not to interfere with the strength of the pulley. In the case of the pulley for fiat belt, we should suggest the cross-holes shown as offering a better escape for air than blind holes.

Removing Pins with Sheared Dowels.

IN many eases pins with round heads

are used in connection with such parts as brake work, etc.; these pins are usually provided with small dowels under the head to prevent them from turning round. When dismantling, it is often found that these small dowels have been sheared off through lack of lubrication, and consequent seizure, or have worn away through vibration. When this has happened it is very difficult to hold the pin from turning round while removing the nut, especially if the latter be rusted up. Footprints and other grippers are often used, but owing to the heads usually being very thin it is not easy to get a firm hold of them.

" D.D.I.," of Cleckheaton, suggests that wherever a lathe is installed there is always a three-jaw chuck, and this he takes off the lathe and tightens on to the head of the offending bolt. He finds that this always affords sufficient grip to enable even the most obstinate of nuts to be undone.

A Garage Funnel with a Ball Valve.

THERE are oases when the filling of a petrol tank by means of a funnel is no simple matter as there is the risk of over-filling, and the consequent spilling of petrol, which is both wasteful and dangerous.

To prevent this one has to be continually lifting the funnel and looking into the tank to see the level of the petrol therein, and the petrol must be fed in small quantities, as none can remain in the funnel.

A suggested funnel wkich has a valve in its mouth is the idea of " H.A.B.," of Rotherham, and he says he has found this very useful, as he is able to watch the level, and should it be high enough he can withdraw his funnel while some petrol still remains in it, without the fear of spilling any.

The funnel is orthodox, excepting that where the cone joins the spout he fits a brass seating and a smooth lead ball with a chain attached so that by lowering the ball he can shut off the supply, and return to the petrol can any petrol that may be left in the funnel.

Such a funnel as this should prove most serviceable in the garage and prove a considerable time-saver.