CONDITIONS WHICH AFFECT LUBRICATION.

Page 49

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

The Second of a Short Series of Articles on a Vital Subject. The Working Conditions of an Engine are Carefully Analysed.

IN the first article upon the subject of the function ' of lubricants and their choice for given sets of conditions we dealt with the question of the operating costs of commercial motor vehicles and then made the definite assertion that the costs of operation, the life of a vehicle and its availability for employment all largely depend upon the correctness of the lubrication system and upon the right choice of lubricants for the various working parts of the vehicle.

In this, the second article of the series, we shall deal with the engine as a unit, analysing it from a lubrication standpoint and illustrating the features which have to he studied before the correct grades of oil are determined.

Let us take, first of all, the question of heat. All oils thin out under heat. The higher the temperature the thinner becomes the oil subjected to the heat. Some oils lose body quickly, others at a comparatively slow rate, the change depending upon their original body and character. To be correct for any engine, the oil employed for its lubrication must be of such a character that, when it is brought to the extreme temperature encountered in the operation of the engine, it will still possess sufficient body to maintain an unbroken protective film between the frictional surfaces. It follows, therefore, that the oper.ting temperatures of an engine must first be ascertained—that is, within reasonable These factors being known, and with an acquired knowledge of the behaviour of various lubricants at different temperatures, an oil of the correct body and character can he selected to meet the conditions encountered, and it must be remembered that the operating temperatures of an engine are largely affected by the service it performs. For example, farm tractor service entails sustained heavy work interposed with brief idling, i.e., slow-running periods resulting in high temperatwres, whereas commercial vehicle service entails variable loads, sometimes with frequent idling, i.e., slow running and frequent stops, resulting generally in moderate to high temperatures. These, again, are affected by the cooling system employed, because the thermo-siphonic system of water cooling usually promotes higher temperatures than pump circulation. These, however, are not the only points involved. The engine speed, the cylinder bore, the valve arrangement and the materials used in the construction of the engine are other features of design which directly affect operating temperatures.

If all these factors exert their influence towards producing high temperatures, a heavy, bodied lubricant of such character as will function well under heat is, obviously, desirable, and such an oil should be used, provided that further analysis indicates that it will readily reach all the frictional surfaces ; that its use will not result in the formation of excessive carbon deposit, and that it is well adapted to seal the piston rings. Similarly, if analysis from the heat standpoint indicates that a. light or medium oil will suffice, an oil of that grade may be used, provided that it has the body and character demanded to satisfy the conditions which control the effectiveness of the distribution system, tend to limit the formation of carbon and which concern piston-ring sealing.

To consider oil distribution—all oils are not -equally free-flowing. Oils of light body are readily distributed through small passages, whilst heavy-bodied oils are less fluid and demand larger passages. Oils of light body are capable of being readily atomized, but heavy-bodied oils resist the process of atomization which is essential to even distribution in some lubricating systems.

It would be unwise to put into an engine an oil that was not adapted to feed freely and under the most severe conditions through the passages provided to conduct it to the various frictional surfaces. It would be equally short-sighted to use an oil lacking in those qualities necessary to ensure its thorough distribution in some particular lubricating system. The ability of the lubricating system to deal with oils of various grades under service conditions must be determined before the correct oil can be selected.

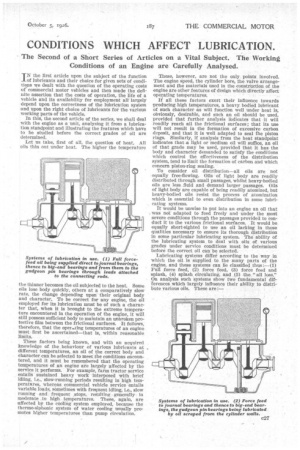

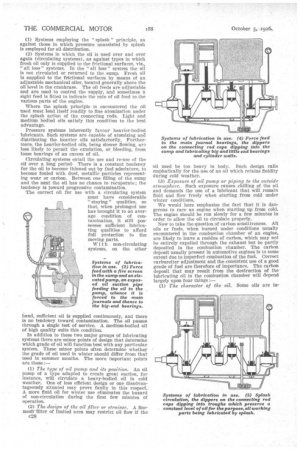

Lubricating systems differ according to the way in which the oil is supplied to the many parts of the engine, and these systems can 15e classified thus :—(1) Full force feed, (2) force feed, (3) force feed and splash, (4) splash circulating, and (5) the "all loss." On analysis such systems show two fundamental differences which largely, influence their ability to distribute various oils. These are (1) Systems employing the " splash" principle, as against those in which pressure unassisted by splash is employed for oil distribution.

(2) Systems in which the oil is used over and over again (circulating systems), as against types in which fresh oil only is supplied to the frictional surfaces, viz., "all loss" systems. In the "all loss" system the oil is not circulated or returned to the sump. Fresh oil is supplied to the frictional surfaces by means of an adjustable mechanical oiler, located generally above the oil level in the crankcase. The oil feeds are adjustable and are used to control the supply, and sometimes a sight feed is fitted to indicate the rate of oil feed to the various parts of the engine.

Where the splash principle is encountered the oil used must lend itself readily to fine atomization under the splash action of the connecting rods. Light and medium bodied oils satisfy this condition to the best advantage.

Pressure systems inherently favour heavier-bodied lubricants. Such systems are capable of atomizing and distributing the heavier oils satisfactorily. Furthermore, the heavier-bodied oils, being slower flowing, are less likely to permit the exudation, or bleeding, from loose bearings of an excess of oil.

Circulating systems entail the use and re-use of the oil over a long period. There is a constant tendency for the oil to become thinned out by fuel admixture, to become fouled with dust, metallic particles representing wear or carbon. Between one filling of the sump and the next the oil has no chance to recuperate ; the tendency is toward progressive contamination.

The correct oil for use with a circulating system must have considerable " staying" qualities, so that, when prolonged use has brought it to an average condition of contamination, it still possesses sufficient lubricating qualities to afford full protection to the moving parts.

With non-circulating Systems, on the other hand, sufficient oil is supplied continuously, and there is no tendency toward contamination. The oil passes through a single test of service. A medium-bodied oil of high quality suits this condition.

In addition to these two major groups of lubricating systems there are minor points of design that determine which grade of oil will function best with any particular system. These minor points often determine whether the grade of oil used in winter should differ from that used In summer months. The more important points are these :—

(1) The type of oil pump and its position. An oil pump of a type adapted to create great suction, for instance, will circulate a heavy-bodied oil in cold weather. One of less efficient design or one disadvantageously situated may prove faulty in this rasped. A more fluid oil for winter use eliminates the hazard of non-circulation • during the first few minutes of operation.

(2) The design of the oil filter or strainer. A flnemestr filter of limited area may restrict oil flow if the c28 oil used be too heavy in body. Such design calls emphatically for the use of an oil which retains fluidity during cold weather.

(3) Exposure of oil pump or piping to the outside atmosphere. Such exposure causes chilling of the oil and demands the use of a lubricant that will remain fluid and flow freely when starting from cold under winter conditions.

We would here emphasize the fact that it is dangerous to race an engine when starting up from cold. The engine should be run slowly for a few minutes In order to allow the oil to circulate properly.

Now to take the question of carbon sensitiveness. All oils or fuels, when burned under conditions usually encountered in the combustion chamber of an engine, are likely to leave a residue of carbon, which may not be entirely expelled through the exhaust but be partly deposited in the combustion chamber. The carbon deposit usually present in automotive engines is to some extent due to imperfect combustion of the fuel. Correct carburetter adjustment and the consistent use of a good grade of fuel are therefore of importance. The carbon deposit that may result from the destruction of the lubricating oil in the combustion chamber will depend largely upon four things :—

(1) The character of the oil. Some oils are in

herently clean-burning; others burn to gummy, sticky masses; others, again, " coke " to a hard, dry carbon formation.

(2) The body of the oil. Usually oils of heavy body tend towards greater carbon formation than the lighter

bodied lubricants.

(3) The engine-operating temperatures. With any oil the tendency to form carbon is greater over a given range of temperatures. Above this the carbon formed is consumed ; below it the formation goes on at a less rapid rate.

(4Y The quantity of oil reachin.g the combustion chamber. The more oil the more carbon. The amount a oil passed depends on engine design, construction and use.

Before the oil of correct body and character can be determined, every feature of engine design affecting carbon formation must be carefully considered.

• The tendency toward carbon formation with an engine must be examined from three standpoints : (1) Do the operating conditions tend to promote carbon accumulation? If so, in average commercial vehicle service, in contrast to farm tractor or aeroplane service, careful consideration must be given to carbon accumulation.

(2) Is the engine construction such that an excessive amount of oil will work past the piston rings into the combustion chamber? Where too much oil is certain to reach the combustion chamber because of features of design which control the oil supply, it is essential that the oil used be of clean-burning character and preferably of light or medium body.

(3) Is the engine of a type in which a slight amount of carbon interferes seriously with its performance? Engines employing high compressions tend to " knock " when carbon is present to a greater extent than do engines of either medium or low-compression types. The shape of the combustion head has an important bearing on the tendency towards fuel detonation, and It is therefore necessary that the greatest care be exercised in the selection of a lubricant to reduce any " knocking " tendency to a minimum.

On the matter of piston ring seal, the ability to spread, adhere, " film " and seal varies with different oil's. These properties depend somewhat on oil body ; more largely, however, on oil character.

Failure of the oil to seal the piston rings is seriously detrimental to satisfactory engine performance. On the compression stroke part of the fuel charge escapes and is wasted, particularly with a cold engine ; compression is reduced and as a result the explosion pressure is lowered. Further, leakage of the burning gases reduces the power and, in escaping by the piston rings, removes part of the lubricating film, which defect, if allowed to continue, will result in premalure wear, and in extreme cases serious damage may occur. Rapid contamination of the oil in the sump also results.

In order to prevent these troubles, the oil must be of the proper body and character to seal the rings under the temperature and pressure conditions prevailing.

The major features affecting piston ring seal are the number and the fit of the rings, the engine load and speed, the operating temperatures and tendency towards fuel dilution. With an adequate number of rings the tendency towards the gases blowing past the piston is minimized and lighter-bodied lubricants provide an• adequate seal. If the engine speed be high there is insufficient time for the gases to displace the oil film, but, on the other hand, with slow-speed engines the greatest possible sealing ability in the oil is desired, particularly if the engine operates under heavy loads.

With high operating temperatures the sealing ability of the oil is reduced, but a much more serious reduction takes place if the conditions are such that unvaporized fuel continually tends to dilute and to thin out the oil film on the cylinder walls and the oil supply in the crankcase. In such cases the utmost possible sealing quality is desirable in the oil, providing that some other detrimental result be not introduced.

It is also important, under normal conditions of design and operation, that too heavy an oil should not be used, as it tends to create excessive carbonization, valve sticking and fluid friction drag, thereby reducing engine efficiency. Each point affecting these conditions must be carefully considered with respect to oil character and oil body before determining the correct grade for use in any given unit.

(To be continued.)