FROZEN ASSETS

Page 40

Page 41

Page 42

If you've noticed an error in this article please click here to report it so we can fix it.

• It's more than two years since the UK Food Hygiene Regulations were put in place, governing temperature requirements for food in transit and demanding "due diligence" from all concerned. The effect on the food distribution industry has been extensive and costly and there are more regulations in the pipeline that might be aligned with ATP laws.

There are EC Frozen and Chilled Foods Directives on the way which are based on UK requirements but could be more stringent. The Department of Transport is believed to be about to start discussions in Geneva to argue for a practical, more acceptable form of the ATP regs rather than simply a blanket adoption.

The present rules, and those due for next April lower the required limit for some foods in transit from -8°C to -5'C, place the onus for compliance on every link in the "cold chain", especially the hauliers who must monitor temperatures and record them to prove their own due diligence.

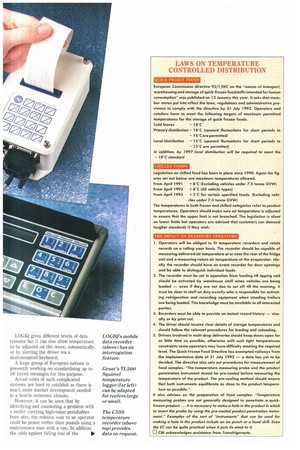

There is an abundance of such data-sensing and logging equipment available, ranging from the long-established Adams disc-type recorders to advanced electronic systems.

This wide choice in the market brings its own problems because of their non-compatibility.

For example, it's no good having a delivery of perishables when the customer does not have the means to down-load the necessary information before receiving them.

STANDARDISATION

Many operators believe that there should be standardisation, even EC type-approval if necessary, along the lines of the early tachographs. In this way, the number of suppliers would be reduced, and with economies of scale, some of the unreclairnable cost of complying with the Food Regs would be clawed back.

Some of the more advanced systems around include those that can be linked via various telephone arrangements and even satellites, providing data that can be digested by complete business management networks.

An example of this type of equipment is the system under evaluation by Hargrave International with its recently acquired fleet of high-specification artic reefers.

Built by Gray and Adams and fitted with RAM electronic monitoring equipment, Hargrave is able to keep a check on air temperatures, defrost cycles and container door openings and closings. In-cab links give audio/visual alarms. Hargrave is also analysing Leyland Daf's LOGIQ vehicle management system which can locate a vehicle and assess its speed and fuel useage. LOGIQ uses an on-board computer linked via a radio/cellnet phone or satellite system to the vehicle's base or central office.

HI can then collect data from one of its vehicles anywhere in the UK or on the Continent, analyse it and alert the driver if necessary. LOGIQ gives different levels of data transfer but it can also allow temperature to be adjusted on the move, automatically, or by alerting the driver via a dash-mounted keyboard.

A large group of European nations is presently working on standardising up to 50 keyed messages for this purpose.

Actual costs of such complicated systems are hard to establish as there is much more market development needed in a hostile economic climate.

However, it can be seen that by identifying and countering a problem with a reefer carrying high-value perishables from afar, the relative cost to an operator could be pence rather than pounds using a maintenance man with a van. In addition the odds against failing foul of the Food Regulations are that much longer.

As far as temperature monitoring and data logging goes, most major food distribution businesses already have their eyes on the ball. they ensure that their vehicles are equipped with suitable monitoring and recording devices that can be freely interrogated.

Any refusal at the cold store can prove expensive. One cold-chain haulier is Novacold, a Transport Development Group member with 26 cold stores from Aberdeen to Plymouth. Its depots hold many millions of pounds worth of food destined for most of the UK's leading supermarkets.

Novacold has a 60-strong truck and 24-pallet trailer fleet to distribute the footstuffs. The trucks mainly have Schmitz body systems with Carrier and ThermoKing fridge units. As a part of its due diligence responsibilities Novacold is fitting Comark's C550 on-board temperature recorders; the latest seven-channel systems which provide a wide range of data.

Each channel has high and low temperature settings with alarms that can be set by the user to suit the application.

Excessive defrost cycles also trigger the alarm. Three channels are switched to cover chiller operation, door security and defrost operation with safeguards against false alarms. Print-outs from the cab-mounted unit can be supplied on request, to give a summary of journey temperatures. A security keyswitch operates the integral keypad and prevents unauthorised alterations to the alarm.

TAMPERING

System security came sharply into focus a couple of years ago when "copycat" tampering of foodstuffs regularly made the headlines.

As the Food Hygiene regs started to take shape, manufacturers began to extend the scope of their sensing and recording equipment, building in safeguards as well as developing and adding to their optional features.

One major company, Woodley Electronics, has a range of temperature recorders to suit just about every application, from refrigerated panel vans to the largest reefer semi-trailers.

Its Vantemp device fits in the cabs of smaller rigids and continuously monitors and displays up to four temperatures. Like several similar systems it works from a variety of sensors inside the body, briefly displaying readings sequentially for the driver's benefit. A diagnostic routine automatically checks out performance white a Keyiogger package or a local printer gives proof of temperatures and "events".

WoocIley's Truktemp for larger reefers is both a temperature monitor and alarm system with print-out and data logging.

Other manufacturers specialising in temperature sensing include Zeal with its RDS Therrnoprint programmable recorder. This is now available with a 32K real-time memory for multi-drop deliveries.

It will produce a full temperature print-out at each drop or at selected intervals and lets the driver run off a full day's work record at his depot.

LOGGING

Grant Instruments has a well-established system aimed at logging temperatures of frozen and chilled foods in vehicles large or small. 500 Series Squirrel recorders can accept up to eight event inputs to monitor door movements and fridge operation and includes a variety of alarms for the driver.

Among the options, Grant offers the use of a Psion organiser to download data from one or more Squirrels via a high-speed infra-red link to a printer.

Most temperature recording devices are designed to oversee the working of the fridge unit and to react accordingly.

There has to be a fair degree of compatibility and the chiller manufacturers are torn between having preferred makes and producing their own devices; they have the technology and in today's climate, it would bring them much-needed work.

The two largest fridge makers, Carrier and ThermoKing each go their own way in this respect. Carrier prefers to market Zeal's Thermoprint system while ThermoKing now produces its own DMS temperature management and recording equipment that can regulate conditions over an entire journey. This package aimed at taking monitoring and decision making away from the driver.

by Bryan Jarvis