TEANITUR108 Flywheel power

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

The lack of a suitable type of infinitely variable reversible transmission has hindered the use of flywheel energy as an auxiliary source of power. Paul Brockington looks at the SRF drive-line developed in Isreal, which could point the way to bigger things

'SEVERAL MANU

FACTURERS have belittled the flywheel as the main or auxiliary form of motive power for commercial vehicles since I wrote a Technitopics on "Flywheel aided power surge" (CM October 30, 1970).

They have done this despite the repeated claim by some manufacturers that the flywheel could be successful in one form or another given the development of the reversible indefinitely variable type of transmission.

The operational viability of the Oerlikon Gyrobus flywheel-propelled vehicle as demonstrated in Switzerland and the then Belgian Congo over 10 or more years has never been seriously regarded as an indication of the potential of the system for general • application. The need for it to re-energize at stops every halfmile is a necessity which could only be justified in a very special application.

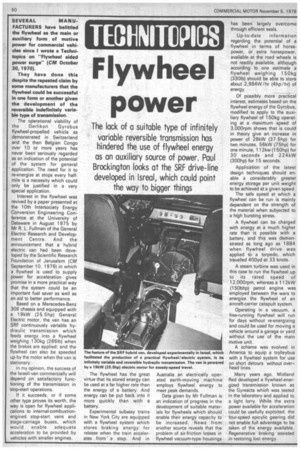

Interest in the flywheel was revived by a paper presented at the 10th Intersociety Energy Conversion Engineering Conference at the University of Delaware in August 1975 by Mr R. L. Fullman of the General Electric Research and Development Centre. And the announcement that a hybrid electric van had been developed by the Scientific Research .Foundation of Jerusalem (CM September 10, 1976) in which a flywheel is used to supply power for acceleration gives promise in a more practical way that the system could be an important fuel saver as well as an aid to better performance.

Based on a Merecedes-Benz 306 chassis and equipped with a 19kW (25.5hp) General Electric motor, the van has an SRF continuously variable hydraulic transmission which feeds energy into a flywheel weighing 130kg (2861b) when the brakes are applied; and the flywheel can also be speeded up by the motor when the van is stationary.

In my opinion, the success of the Israeli van commercially will depend on satisfactory functioning of the transmission in stop-start operations.

If it succeeds, or if some other type proves its worth, the way is open for flywheel applications to internal-combustionengined stop-start vans and stage-carriage buses, which would enable adequate acceleration to be provided by vehicles with smaller engines. The flywheel has the great virtue that its stored energy can be used at a far higher rate than the energy of a battery. And energy can be put back into it more quickly than with a battery.

Experimental subway trains in New York City are equipped with a flywheel system which stores braking energy for release when the train accelerates from a stop. And in Australia an electrically operated earth-moving machine employs flywheel energy to meet peak demands.

Data given by Mr Fullman is an indication of progress in the development of suitable materials for flywheels which should enable their energy capacity to be increased. News from another source reveals that the problem of air-friction losses in flywheel vacuum-type housings has been largely overcome through efficient seals.

Up-to-date information regarding the potential of a flywheel in terms of horsepower, or extra horsepower, available at the road wheels is not readily available, although according to one estimate a flywheel weighing 150kg (330Ib) should be able to store about 2,984W /hr (4hp/hr) of energy.

Of possibly more practical interest, estimates based on the flywheel energy of the Gyrobus, modified to apply to the auxiliary flywheel of 150kg operating at a maximum speed of 3,000rpm shows that is could in theory give an increase in power of 28kW (37.5hp) for two minutes, 56kW (75hp) for one minute, 112kw (150hp) for 30 seconds and 224kW (300hp) for 15 seconds.

Application of the latest design techniques should enable a considerably greater energy storage per unit weight to be achieved at a given speed.

The safe speed at which a flywheel can be run is mainly dependent on the strength of the material when subjected to a high bursting stress.

A flywheel can be charged with energy at a much higher rate than is possible with a battery, and this was demonstrated as long ago as 1884 when flywheel drive was applied to a torpedo, which travelled 400yd at 33 knots.

A steam turbine was used in this case to run the flywheel up to its rated speed of 12,000rpm, whereas a 112kW (150bhp) petrol engine was employed between the wars to energize the flywheel of an aircraft-carrier catapult system.

Operating in a vacuum, a free-running flywheel will run for days without re-energizing and could be used for moving a vehicle around a garage or yard without the use of the main motive unit.

A scheme was evolved in America to equip a trolleybus with a flywheel system for use on short detours without overhead lines.

Many years ago, Midland Red developed a flywheel-energized transmission known as the Gyreacta which was tested in the laboratory and applied to a light lorry. While the extra power available for acceleration could be usefully exploited, the four-speed epicylic gearing did not enable full advantage to be taken of the energy available_ Regenerative braking assisted in restoring lost energy.