Seddon makes first use of Perkins V8 in standard r

Page 58

Page 59

Page 60

If you've noticed an error in this article please click here to report it so we can fix it.

THE first use of the new Perkins V8.5I0 engine in a range of commercial vehicles has been made by Seddon Diesel Vehicles Ltd. This unit is used in the new Seddon 16:four announced today (Friday), the range i of four-wheelers including three rigids designed for operation at 16 tons gross and a tractive unit suitable foruse . at 28 tons gross train weight. In the latter case, the model

, designation is 28-4-V8 and an example of this chassis will 1 I be featured at the Glasgow Show on the stand of Central I Motors (Calderbank) Ltd.

The tractive unit has a wheelbase of 9 ft. 3 in. and the other three models in the range are a 12-ft. 6-in.-wheelbase , tipper chassis and two for normal haulage with wheelbases of 14 ft. 8 in. and 16 ft. 9 in. Estimated weights of chassis/cabs range from 4 tons to 4 tons 4 cwt., according to wheelbase.

Similarity to 13:four Like the 13:four, which was introduced for last year's Earls Court Commercial Motor Show, the 16:four is based on a design concept which includes the requirement that the same components shall be used on each of the four models where possible and that there shall be little variation from the standard specification. As a result of this there is no difference between the four models at the forward end and manufacturing chassis in the different wheelbases is made easier.

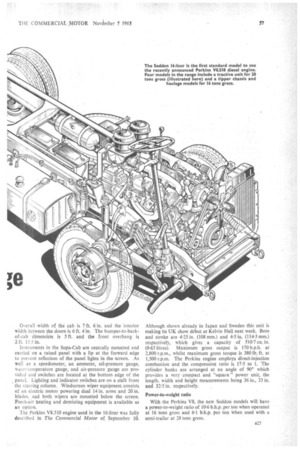

a24 The cab used on the 16:four is the one which was produced for the 13:four, the only difference being in the model name plate. It is called the Seddon Supa-Cab and is of all-steel construction with boxed perimeter framing and one-piece pressed door frames. A forward-entry layout gives easy access into the cab, whilst access across the cab is not difficult because of the low height of the engine cover. The cab is mounted on two Silentbloc bonded rubber/steel units at the rear and rubber cushions at the front which absorb vibration and flexing of the chassis frame.

Internal fittings and trim are to a good standard and excellent forward visibility is provided by a 26 in. by 6 ft. 6 in. one-piece " wrap-round " windscreen. All. round visibility is helped by two deep, rear quarter lights and a central rear window, whilst the forward-binged doors have full-drop windows and opening quarter lights. Tho doors run the full depth of the cab to cover the entrance steps when they are closed. Overall width of the cab is 7 ft. 6 in. and the interior width between the doors is 6 ft. 4 in. The bumper-to-backof-cab dimension is 5 ft. and the front overhang is 2 ft, 11.5 in.

Instruments in the Supa-Cab are centrally mounted and carried on a raised panel with a lip at the forward edge to prevent reflection of the panel lights in the screen. As well as a speedometer, an ammeter, oil-pressure gauge, water-temperature gauge, and air-pressure gauge are provided and switches are located at the bottom edge of the panel. Lighting and indicator switches are on a stalk from the steering column. Windscreen wiper equipment consists of an electric motor powering dual 14 in. arms and 20 in, blades, and both wipers are mounted below the screen. Fresh-air heating and demisting equipment is available as an option.

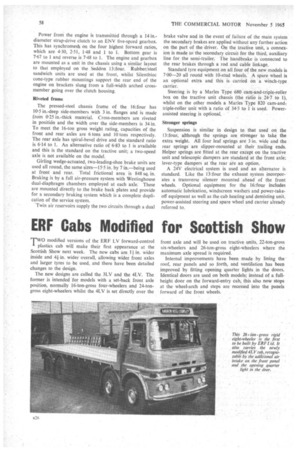

The Perkins V8.510 engine used in the 16:four was fully described in The Commercial Motor of September 10.

Although shown already in Japan and Sweden this unit is making its UK show debut at Kelvin Hall next week. Bore and stroke are 4-25 in. (108 mm.) and 4.5 in. (114.3 mm.) respectively, which gives a capacity of 510.7 cu. in.

(8.63 litres). Maximum gross output is 170 b.p.h. at 2,800 r.p.m., whilst maximum gross torque is 380 lb. ft. at 1,500 r.p.m. The Perkins engine employs direct-injection combustion and the compression ratio is 17.5 to 1. The cylinder banks are arranged at an angle of 90° which provides a very compact and "square" power unit, the length, width and height measurements being 36 in., 33 in. and 32.5 in. respectively.

Power-to-weight ratio

With the Perkins V8, the new Seddon models will have a power-to-weight ratio of 10.6 b.h.p. per ton when operated at 16 tons gross and 6.1 b.h.p. per ton When used with a semi-trailer at 28 tons gross. Power from the engine is transmitted through a 14 in.diameter strap-drive clutch to an ENV five-speed gearbox. This has synchromesh on the four highest forward ratios, which are 4-30, 2.51, 1-48 and I to 1. Bottom gear is 7.67 to 1 and reverse is 7-48 to I. The engine and gearbox are mounted as a unit in the chassis using a similar layout to that employed on the Seddon 13:four. Rubber/steel sandwich units are used at the front, whilst Silentbioc cone-type rubber mountings support the rear end of the engine on brackets slung from a full-width arched crossmember going over the clutch housing.

Riveted frame The pressed-steel chassis frame of the 16:four has 10.5 in.-deep side-members with 3 in. flanges and is made frOm 0.25 in.-thick material. Cross-members are riveted in position and the width over the side-members is 34 in. To meet the 16-ton gross weight rating, capacities of the front and rear axles are 6 tons and 10 tons respectively. The rear axle has spiral-bevel drive and the standard ratio is 6-14 to 1. An alternative ratio of 6.83 to 1 is available and this is the standard on the tractive unit; a two-speed axle is not available on the model.

Girling wedge-actuated, two-leading-shoe brake units are used all round, the same sizes-15-5 in. by 7 in.—being used at front and rear. Total frictional area is 848 sq. in. Braking is by a full air-pressure system with Westinghouse dual-diaphragm chambers employed at each axle. These are mounted directly to the brake back plates and provide for a secondary braking system which is a complete duplication of the service system.

Twin air reservoirs supply the two circuits through a dual

brake valve and in the event of failure of the main system the secondary brakes are applied without any further action on the part of the driver. On the tractive unit, 'a connexion is made to the secondary circuit for the third, auxiliary line for the semi-trailer. The handbrake is -Connected to the rear brakes through a rod and cable linkage.

Standard tyre equipment on all four of the new models is 7.00-20 all round with 10-stud wheels. A spare wheel is an optional extra and this is carried on a winch-type carrier.

Steering is by a Marks Type 680 cam-and-triple-roller box on the tractive unit chassis (the ratio is .24-7 to 1), whilst on the other models a Manes Type 820 "cam-and, triple-roller unit with -a ratio of 34.5 to 1 is used. Powerassisted steering is optional.

Stronger springs Suspension is similar in design to that used on the 131our, although the springs are stronger to take the extra weight. All four leaf springs are 3 in. wide and the rear springs are slipper-mounted at their trailing ends. Helper springs are fitted at the rear except on the tractive unit and telescopic dampers are standard at the front axle; lever-type dampers at the rear are an option.

A 24V electrical system is used and an alternator is standard. Like the 13:four the exhaust system incorporates a transverse silencer mounted ahead of the front wheels. Optional equipment for the 16:four includes automatic lubrication, windscreen washers and power-takeoff equipment as well as the cab heating and demisting unit, power-assisted steering and spare wheel and carrier already referred to.