Rear-engined and Roomy

Page 52

Page 53

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

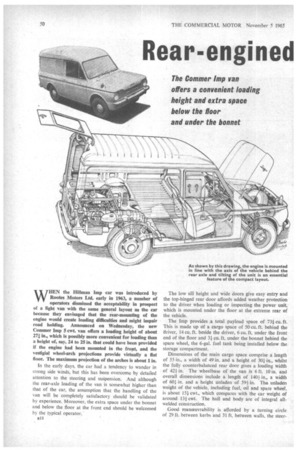

WHEN the Hillman Imp car was introduced by Rootes Motors Ltd. early in 1963, a number of operators dismissed the acceptability in prospect of a light van with the same general layout as the car because they envisaged that the rear-mounting of the engine would create loading difficulties and might impair road holding. Announced on Wednesday, the new Commer Imp 5 cwt. van offers a loading height of about 27+ in., which is possibly more convenient for loading than a height of, say, 24 to 25 in. that could have been provided if the engine had been mounted in the front, and the vestigial wheel-arch projections provide virtually a flat floor. The maximum projection of the arches is about 1 in.

In the early days. the car had a tendency to wander in strong side winds, but this has been overcome by detailed attention to the steering and suspension. And although the rear-axle loading of the van is somewhat higher than that of the car, the assumption that the handling of the van will be completely satisfactory should be validated by experience. Moreover, the extra space under the bonnet and below the floor at the front end should be welcomed by the typical operator.

B18 The low sill height and wide doors give easy entry and the top-hinged rear door affords added weather protection to the driver when loading or inspecting the power unit, which is mounted under the floor at the extreme rear of the vehicle.

The Imp provides ,a total payload space of 731 Cu. ft. This is made up of a cargo space of 50 cu. ft. behind the driver, 14 cu. ft. beside the driver, 6 cu. ft. under the front end of the floor and 31 cu. ft. under the bonnet behind the spare wheel, the 6-gal. fuel tank being installed below the storage compartment.

Dimensions of the main cargo space comprise a length of 55 in., a width of 49 in. and a height of 301-in., whilst the fully counterbalanced rear door gives a loading width of 42+ in. The wheelbase of the van is 6 ft. 10in, and overall dimensions include a length of 140+ in., a width of 601 in. and a height unladen of 594 in. Thu unladen weight of the vehicle, including fuel, oil and spare wheel, is about 151 cwt., which compares with the car weight of around 131 cwt. The hull and body are of integral allwelded construction.

Good manceuvrability is afforded by a turning circle of 29 ft. between kerbs and 31 ft. between walls, the steer ing ratio being 144-15 to 1. A 151 in.-diameter steering rolates 2.6 times from lock to lock.

A notable operational Advantage of rear-engine location as employed on the Imp is that changes_ in the ratio of front-axle to rear-axle loading are relatively small with variations of payload compared with a front-et-Tined vehicle. This reduces variations in handling and braking as between the laden and unladen condition. With an evenly distributed load, the maximum variation in the ratio is plus or minus 7 per cent compared with 2 per cent with the car. When laden, the ratio is 28 per cent front and 72 per cent rear, the car ratio being 35 per cent and 65 per cent respectively.

The engine is mounted in line with the axis of the vehicle at an angle of about 45° to the vertical, the torque being transmitted through a Laycock 51-in.-diaphragm clutch to an all-synchromesh four-speed gearbox in front of the axle. It is significant that the use of aluminium die castings for both units reduces their combined weight to approximately 236 lb. Employing aluminium gives a weight saving of substantially more than -I cwt. compared with typical counterparts and thus correspondingly reduces rear-axle loading. Handling stability is enhanced by employing an independent front suspension giving inherently low cornering power and an independent sYstern at the rear providing high cornering power, the roll centre at the rear being considerably lower than the roll centre of the front end.

Basically similar to the power unit of the standard Imp car, the four-cylinder engine has a bore of 2.677 in. (68 mm.) and a stroke of 2.377 in. (60.375 mm.) which gives a capacity of 53.41 Cu. in. (875 c.c.). Whereas the car engine has a compression ratio of 10 to 1 and develops 39 b.h.p. (net) at 5,000 r.p.m., the ratio of the van unit is reduced to 8 to 1 and its output is derated to 33 b.h.p. (net) at 4,500 r.p.m. Maximum torque rating is 48 lb. ft. at 2,500 r.p.m. which compares with a car-engine rating of 52 lb. ft. at 2,800 r.p.m.

Thermal distortion of the cylinder-block is reduced to a minimum by virtue. of the symmetry of the block about the centre plain, which is facilitated by operation of the valves by overhead camshaft. The cylinder block, a low. pressure aluminium die-casting, has cast-in iron liners. whilst the robust forged-steel crankshaft is carried in three indium-lined, lead-bronze main bearings, the big-end bearings being of similar material. The flat-tapped pistons are equipped with two compression rings and an oil ring above the gudgeon pin.

The wedge-shaped combustion chamber has a substantial squish area and the inclined valves enable the inlet and exhaust ports to be arranged to give "easy flow conditions " for the mixture charge and exhaust gases. The carburetter is a Solex downdraught unit.

Housed in the engine compartment, on the left of the unit, the cowlal radiator is of the no-loss type (water is circulated by a centrifugal pump) and is cooled by a belt-driven fan. Detachable floor panels give ready access to all components requiring routine servicing. The oil filler and dipstick are inset into the floor close to the rear door.

All the four ratios of the gearbox give indirect drive, and the crown wheel of the hypoid final drive, located between the engine and gearbox, meshes with a pinion on the rear end of the layshaft. A high overdrive ratio of 0.852 to I is employed, the third, second and first ratios being 1.174 to 1, 1.833 to 1 and 3.417 to 1 respectively, whilst reverse is 2-846 to 1 and the final drive has a ratioof 4.857 to 1.

Conventional universal joints are used at the outer ends of the articulated half-shafts and Metalastik rubber couplings at the inner ends. The latter give a cushion drive and dispense with the need for splines to accommodate shaft movement.

Because the drive wheels are not steered, constant-velocity joints are not required and this is a favourable cost factor compared with a conventional front-wheel-drive vehicle. The pressed-steel disc wheels are equipped with Dunlop G.72 van type 5.50-12 6-ply tyres.

Of the swing-axle type, the front suspension incorporates curved box-section wishbones with pivots close to the centre line and coil 'springs at the outer ends, telescopic shock absorbers being housed in the springs. The special rack-and-pinion unit of the steering gear has a springloaded nylon damper pad that holds the rack in contact with the pinion and automatically takes up wear.

In the case of the rear wheels, the hubs are mounted on semi-trailing wishbones, the pivot axis of which is angled rearwards so that the extended centre line of each wishbone passes through the wheel hub on the opposite side. Camber and toe-in changes with deflection of the spring and are, therefore, reduced to a minimum; the weight transfer on corners is low and the system tends to cancel brake dive.

The coil springs are located in front of the outer universaljoints and the telescopic shock absorbers are mounted inboard and to the rear of the springs. At both front and rear the springs have a higher rating than the car springs, heavier wishbones are fitted at the rear and the dampers of the rear axles have modified settings to accommodate -the increase_ in loading. At the front, the spring rate is 2451b. per in., whilst the rear springs are rated at .578 lb. per in. Recommended tyre pressures are 25,p.s.i. for the front and 40 p.s.i. for the rear.

:n20 Routine maintenance has been reduced to a minimum by the elimination of greasing points and extension of the oil-drainage mileage interval to 5,000. This interval is also the basis of the remainder of the service schedules.

Hydraulically operated two-leading-shoe brakes are employed at the front and leading-trailing shoes at the rear, which are actuated by a pendant pedal and provide a total lining area of 75 sq. in., the drums in each case having a diameter of 8 in. and a width of 14• in. The pull-up handbrake lever is mounted on the •left of the driver's seat and operates the rear brakes by. means of cables.

Of orthodox unitary construction, the welded steel shell ,. incorporates two built-in cross-members in the front and . a rear cross-member which support the pivots of the front and rear wishbones respectively. The rear member (which.. is of Z-section and bowed forward) also provides support . for the front mounting of the gearbox.

Support for a cross-bearer at the back of the engine compartment, on which the rear of the engine is pedestalmounted, is afforded by two channel-section members bolted to the body structure at the front which extend rearwards to this bearer. At the front and rear, the bump loads are transmitted to the side panels, thence to the roof structure.

The flooring is of ribbed steel sheet and the side, panels are stiffened to reduce drumming by two felt-backed vertical members of top-hat section that mate with a tophat roof stick. The tatter is bonded to the roof with adhesive in the interests of cleanliness and to provide additional stiffness. A doubling panel is welded to the full-length display panel at each end and is also bonded to this panel with adhesive. Additional stiffening of the roof is provided by incorporating multiple transverse ribbing in the panel.

In common with the car, the two front-hinged doors incorporate swivelling quarter-lights and give a free-gap width of 3 ft. 1 in. The instruments are mounted on a facia directly in front of the driver, whilst the levers operating the fights, horn and indicators are within reach of the driver's hands without him removing them from the wheel.

The 32 a.h. battery of the 12-volt negative-earth system is housed on the right of the engine compartment, whilst• the lighting equipment comprises single wing-mounted headlamps, combined flasher and side-lamp units at the front and indicators combined with stop and side lamps on the rear wings.